Safety device of automatic machinery system

By configuring a detection device in the automatic machinery system to determine and stop the automatic machinery, the safety hazard problem of operators entering the working area is solved, efficient operator supply and equipment operation are achieved, and costs and downtime are reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The above and other objects and features of the present invention can be more clearly understood through the following description of the embodiments with reference to the accompanying drawings.

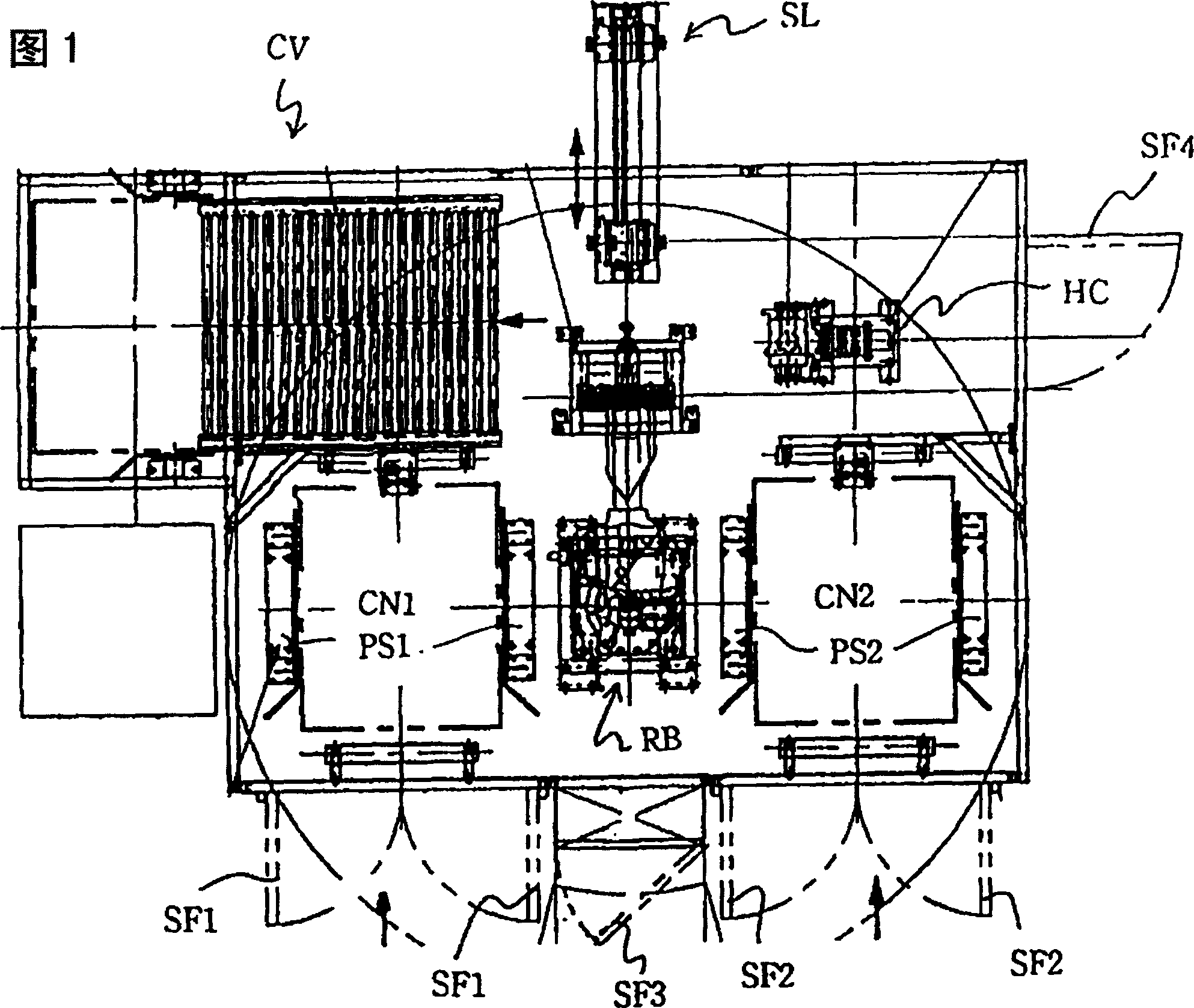

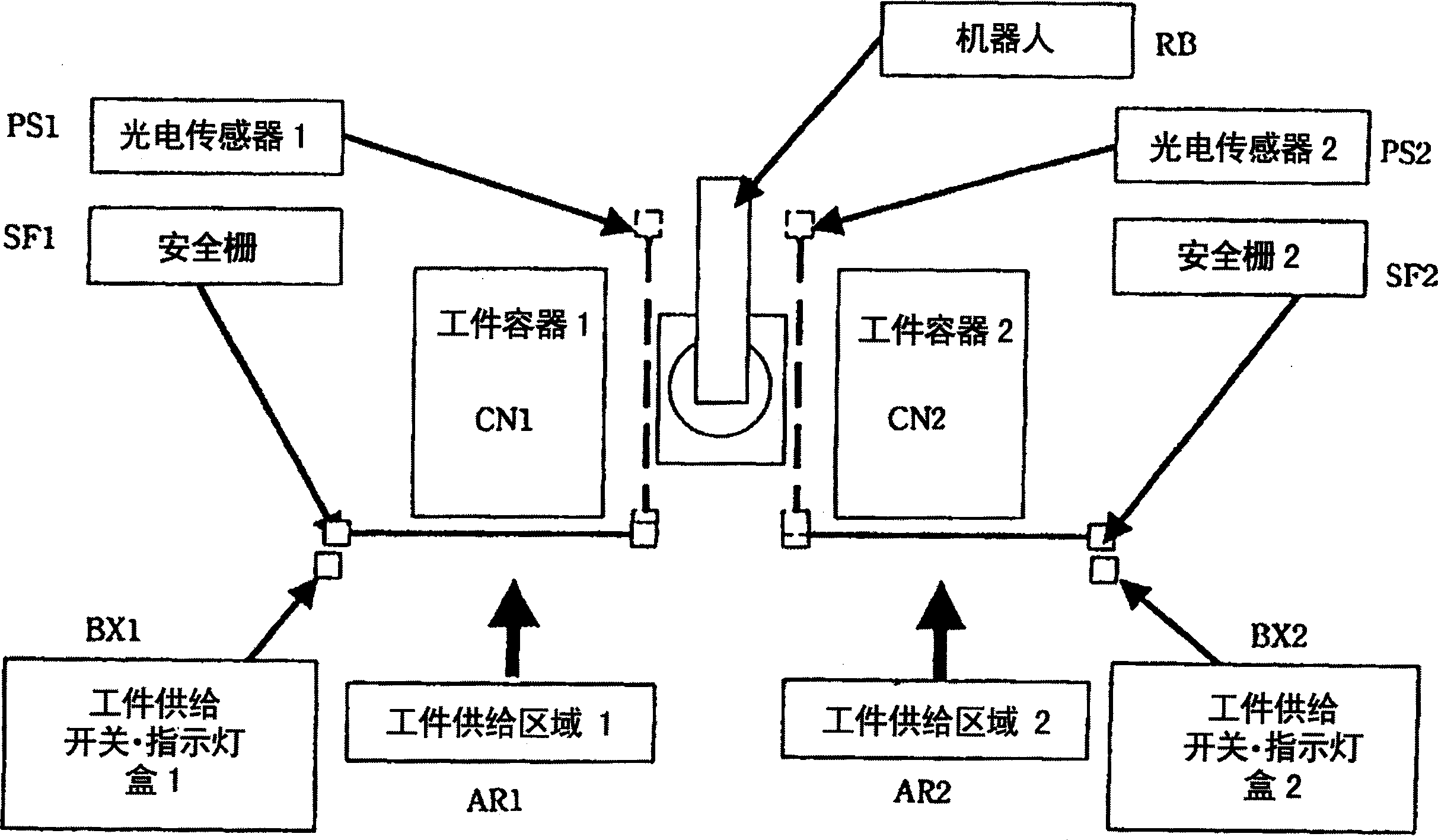

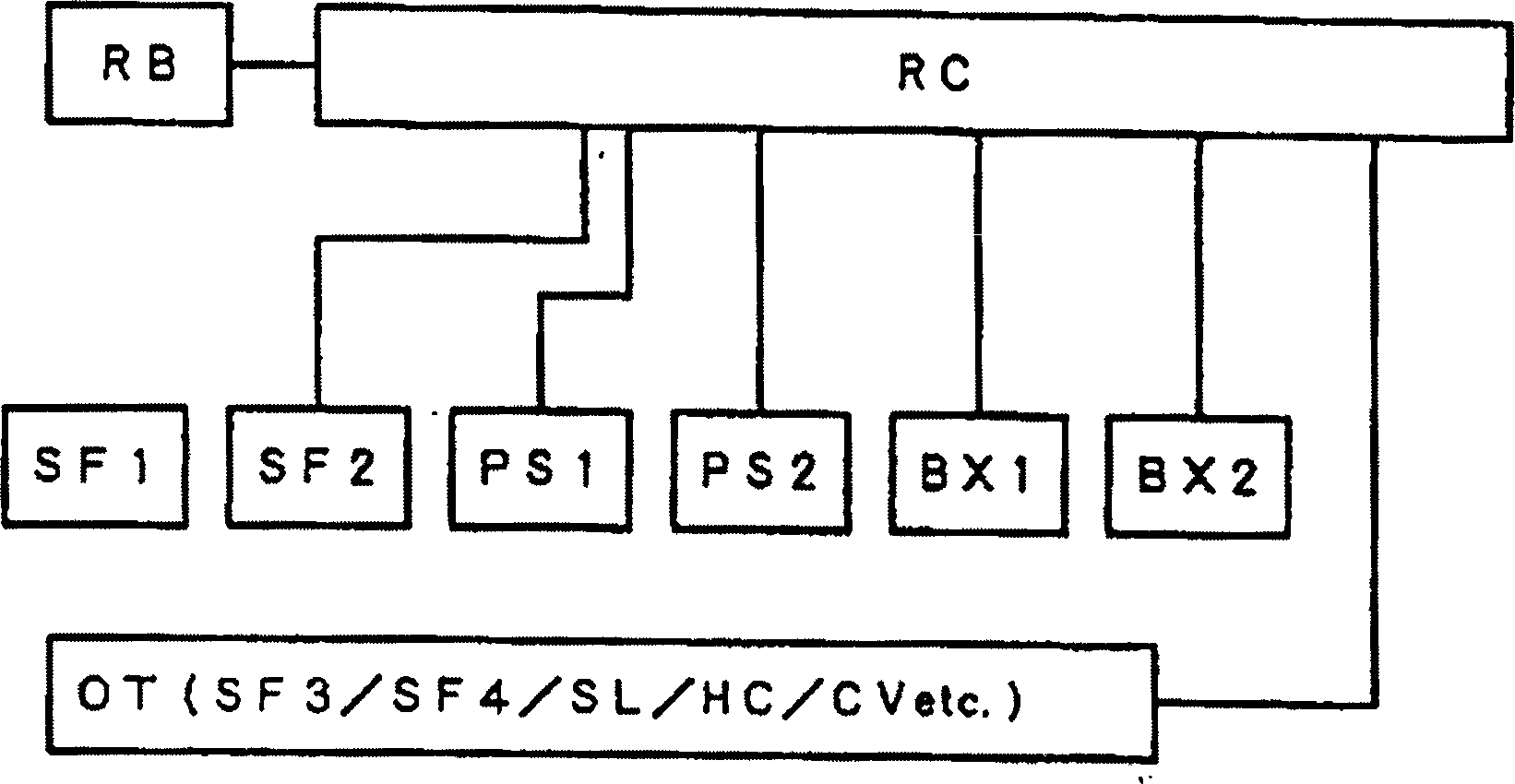

[0015] FIG. 1 is a schematic diagram showing an overall layout of a robot system to which a safety device according to an embodiment of the present invention is applied. figure 2 It is a block diagram that extracts the parts related to the present invention from the general arrangement shown in FIG. 1 and briefly describes them. in addition, image 3 It is a diagram showing the connection relationship between each part of the system and the control device (robot controller) of the system. The present embodiment will be described below with reference to these figures. In addition, although in this embodiment, the automatic machine is used as a robot, and the operation is described as holding and conveying the workpiece, it may also be other automatic machines that perform oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com