Air supply apparatus for air jet loom

A technology of air supply and air injection, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of complicated air supply device, electrical failure of control system, increase of injection pressure loss, etc., to achieve simplification and reduction Effect of using quantity and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0039] [Example 1: Air supply device for monochrome loom]

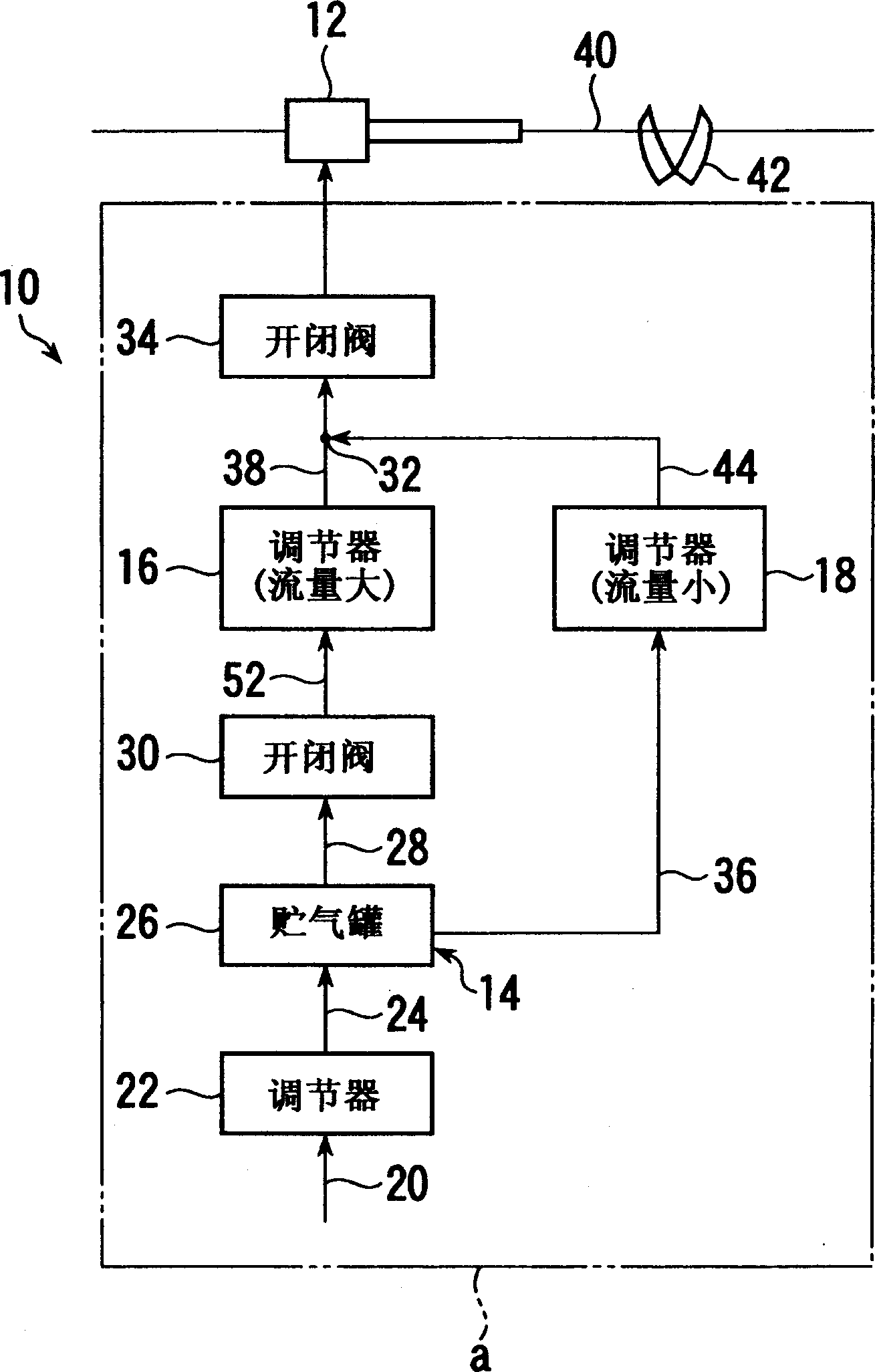

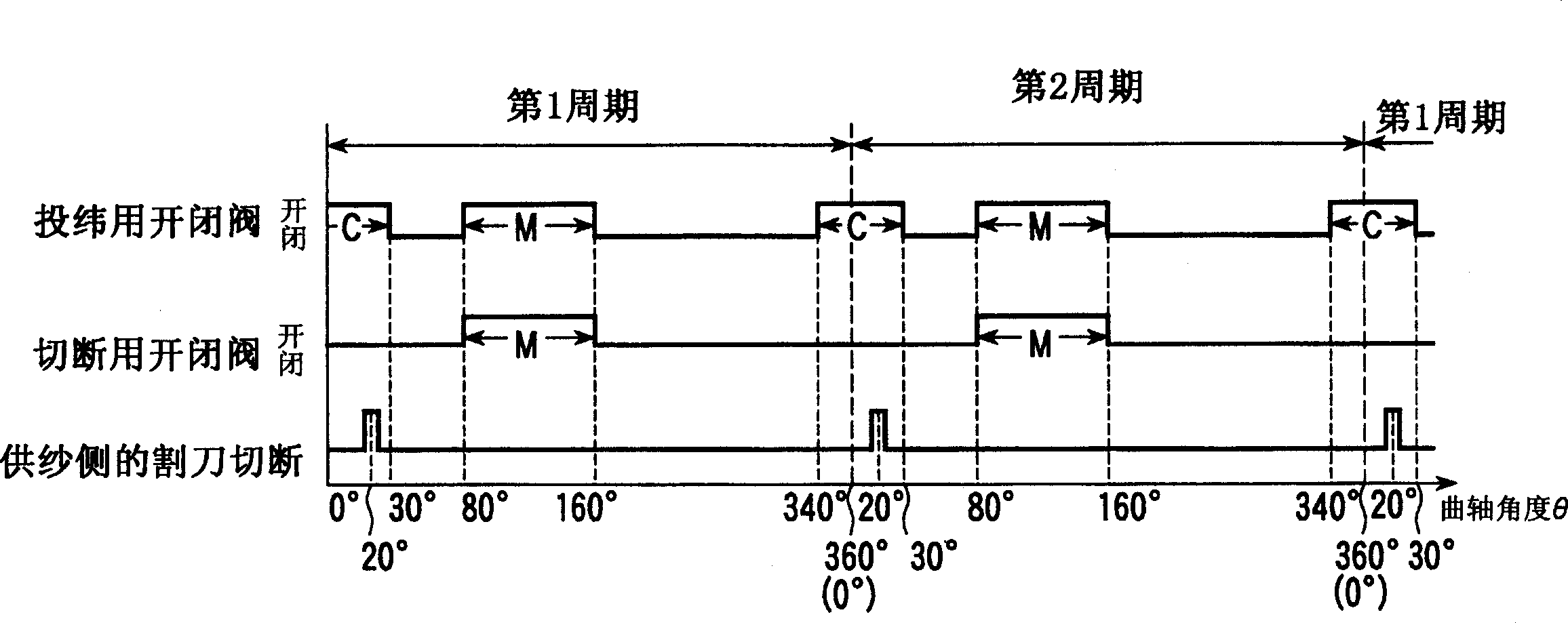

[0040] refer to figure 1 and figure 2 , the air supply device 10 is used for a monochrome loom having one main nozzle 12 .

[0041] The air supply device 10 has a piping circuit a in which compressed air regulators 16 and 18 for weft insertion and cutting are connected in parallel between the compressed air supply source 14 and the main nozzle 12 .

[0042] The compressed air supply source 14 includes: a pressure source (not shown) such as a compressor; an auxiliary compressed air regulator (hereinafter simply referred to as "regulator") 22 connected to the air outlet of the pressure source through a piping 20; A compressed air tank (hereinafter simply referred to as “air tank”) 26 connected to the air outlet of the regulator 22 through a pipe 24 .

[0043] The pipe 28 protruding from one air outlet of the air tank 26 goes from the air tank 26 to the downstream side, passes through the on-off valve 30, the compres...

no. 2 Embodiment

[0055] [Second embodiment: Air supply device for two-color loom]

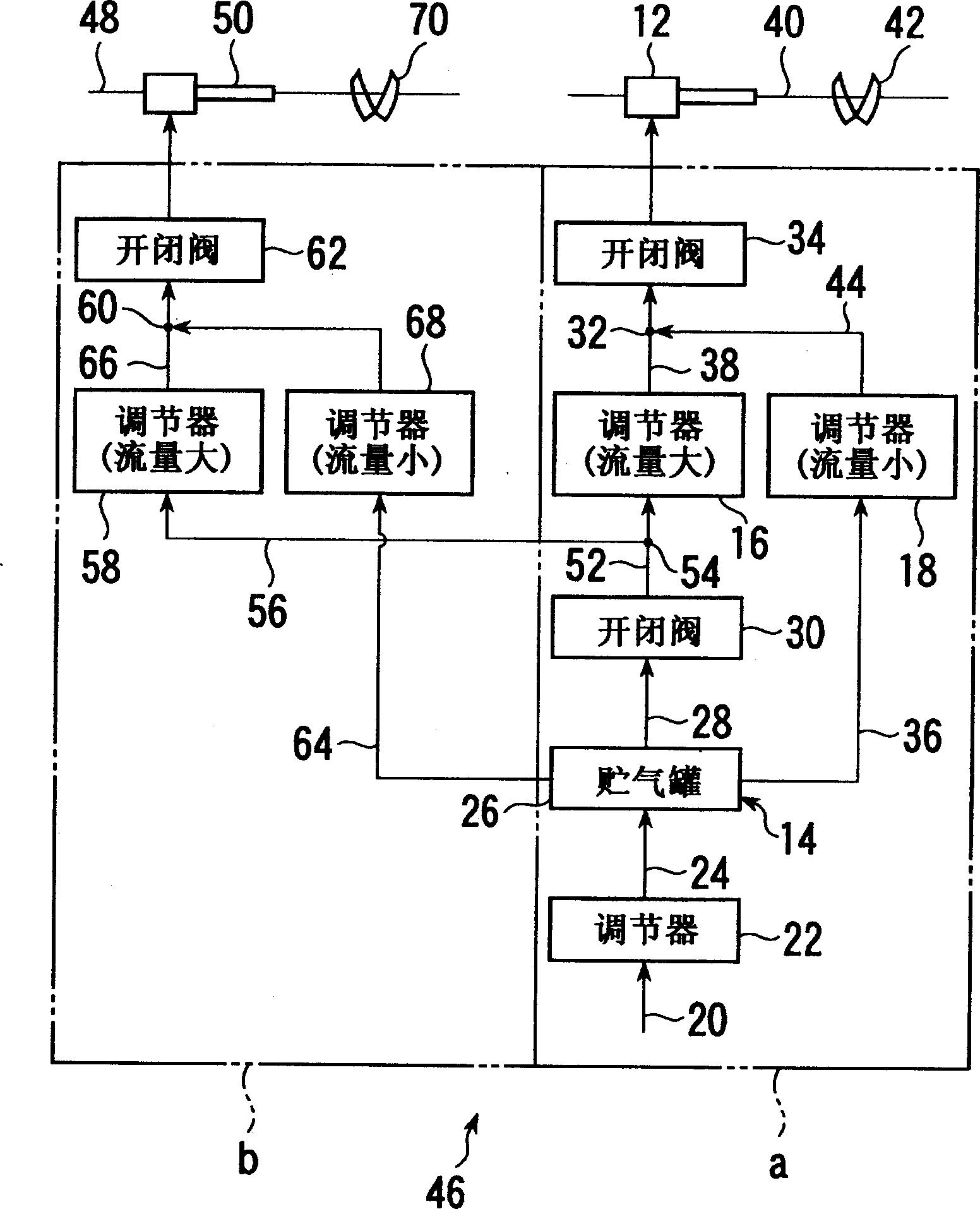

[0056] Please refer to image 3 and Figure 4 In addition to the piping path a in the air supplying device 10, the air supply device 46 also uses a piping circuit equipped with a piping path b that connects the compressed air supply source 14 with the main nozzle 50 that makes other weft yarns 48 fly away, Also, this air supply device 46 is used for a two-color loom.

[0057] The piping line b has a branch line 54 on the piping 52 between the on-off valve 30 and the compressed air regulator 16 . The distribution pipe 56 protruding from the branch path 54 is connected downstream from the branch path 54 to the main nozzle 50 through a compressed air regulator 58 , a confluence path 60 , and an on-off valve 62 in this order. A pipeline 64 extending from the third air outlet of the air tank 14 is connected to a confluence path 60 arranged on a pipe 66 extending from the compressed air regulator 58 through a comp...

no. 3 Embodiment

[0073] [Third embodiment: Air supply device for two-color loom]

[0074] Please refer to Figure 5 In addition to the piping path a in the air supplying device 10, the air supplying device 72 also uses a piping circuit having a piping path b connected to the main nozzle 50 for flying the weft yarn 48, and the air supplying device 72 Can be used on two-color looms.

[0075] The air supply device 72 connects the pipeline 74 that acts as a branch pipeline with the figure 1 The merged passage 32 of the shown air supply device 10 is connected, the merged passage 32 is used as a merged branch passage 76 , and the pipe 74 is connected to the main nozzle 50 through the on-off valve 62 . However, the air supply device 72 may connect the pipe 74 serving as a branch pipe to the pipe extending from the confluence passage 32 of the air supply device 10 to the main nozzle 12, thereby connecting the confluence passage 32 and the vicinity of the pipe 74 Make a confluence branch road 76 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com