Reinforcnig device for ship hatch cover

A technology of reinforcement device and hatch cover, applied in ship hatches/hatch, ship parts, ship construction, etc., can solve problems such as difficulty in meeting the requirements of classification societies, threatening the safety of ships and personnel, and small beam section coefficients , to achieve the best performance, save renovation costs, and increase the section coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

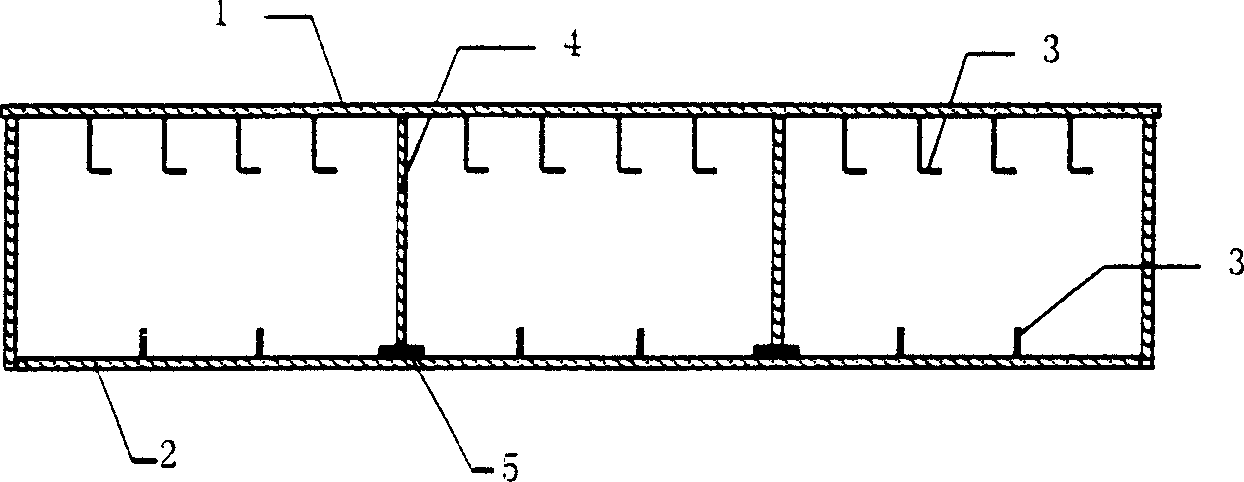

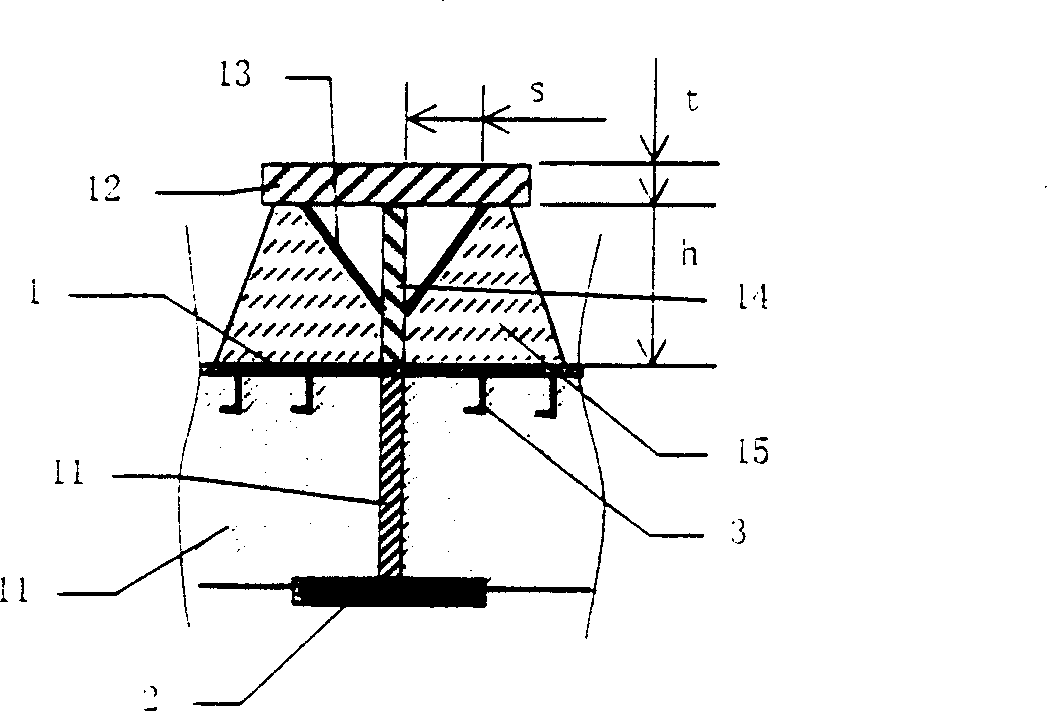

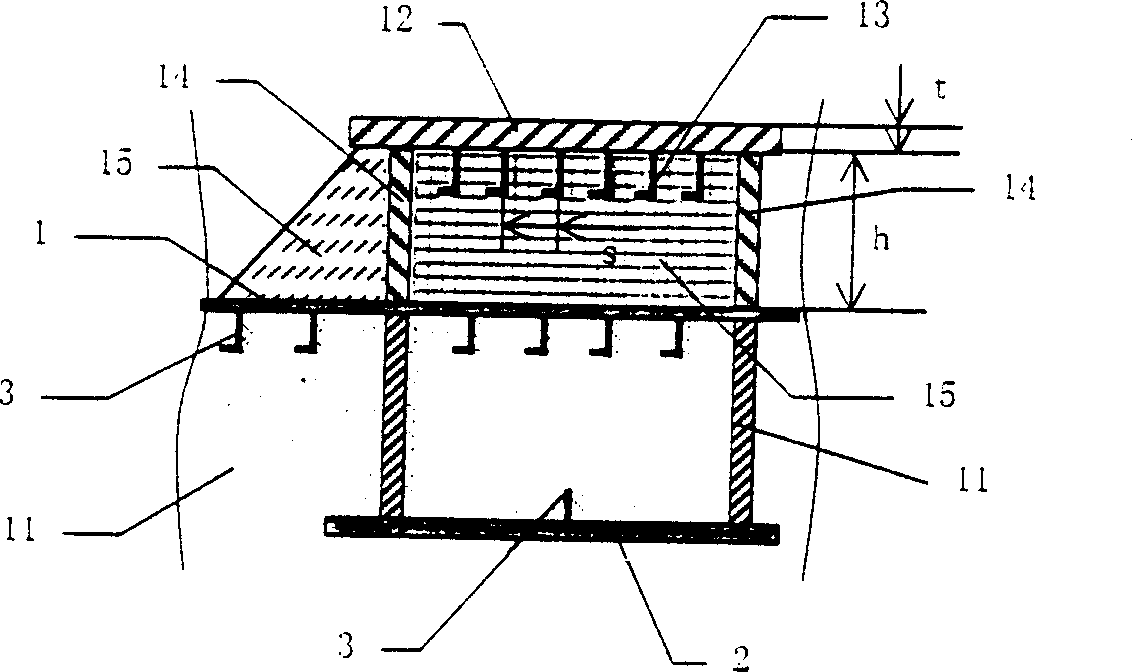

[0024] Such as figure 2 Shown: In order to strengthen the overall strength of the hatch cover and meet the new load specification requirements of the classification society, one or more T-shaped beams with a certain strength are added to the upper part of the original roof 1 of the original hatch cover, and it ( They) are integrated with the main beam inside the hatch cover to form a special new type of beam structure with three wings (panels) in the shape of a "king", making the original flat hatch cover a concave-convex shaped hatch. This new three-sided girder consists of a T-beam section on the outside of the hatch cover and an I-beam section on the inside of the hatch cover. Wherein the I-shaped beam is composed of the original top plate 1, the original beam 3, the internal web 11, and the original bottom plate 2, and the T-beam is mainly composed of the new panel 12, the new beam 13, the external web 14, and the support plate 15; The bottom end of the external web 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com