Shift control apparatus and shift control method for a vehicular automatic transmission

A technology for automatic transmission and shift control, which is applied in the direction of control devices, transmission devices, fluid transmission devices, etc., and can solve problems such as shift shock, fuel efficiency decline, and shift time delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the following description and in the drawings, the invention is described in detail with reference to exemplary embodiments.

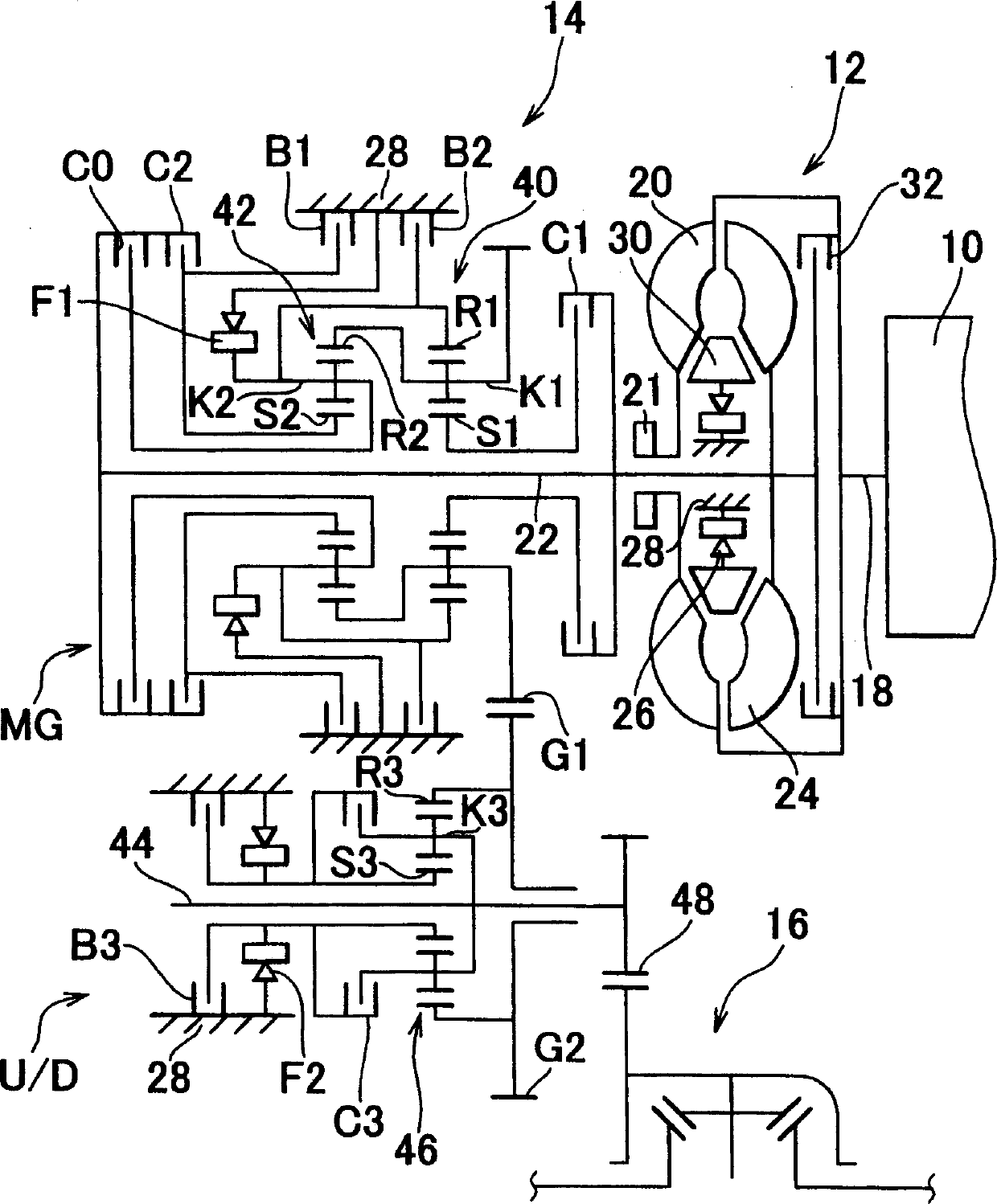

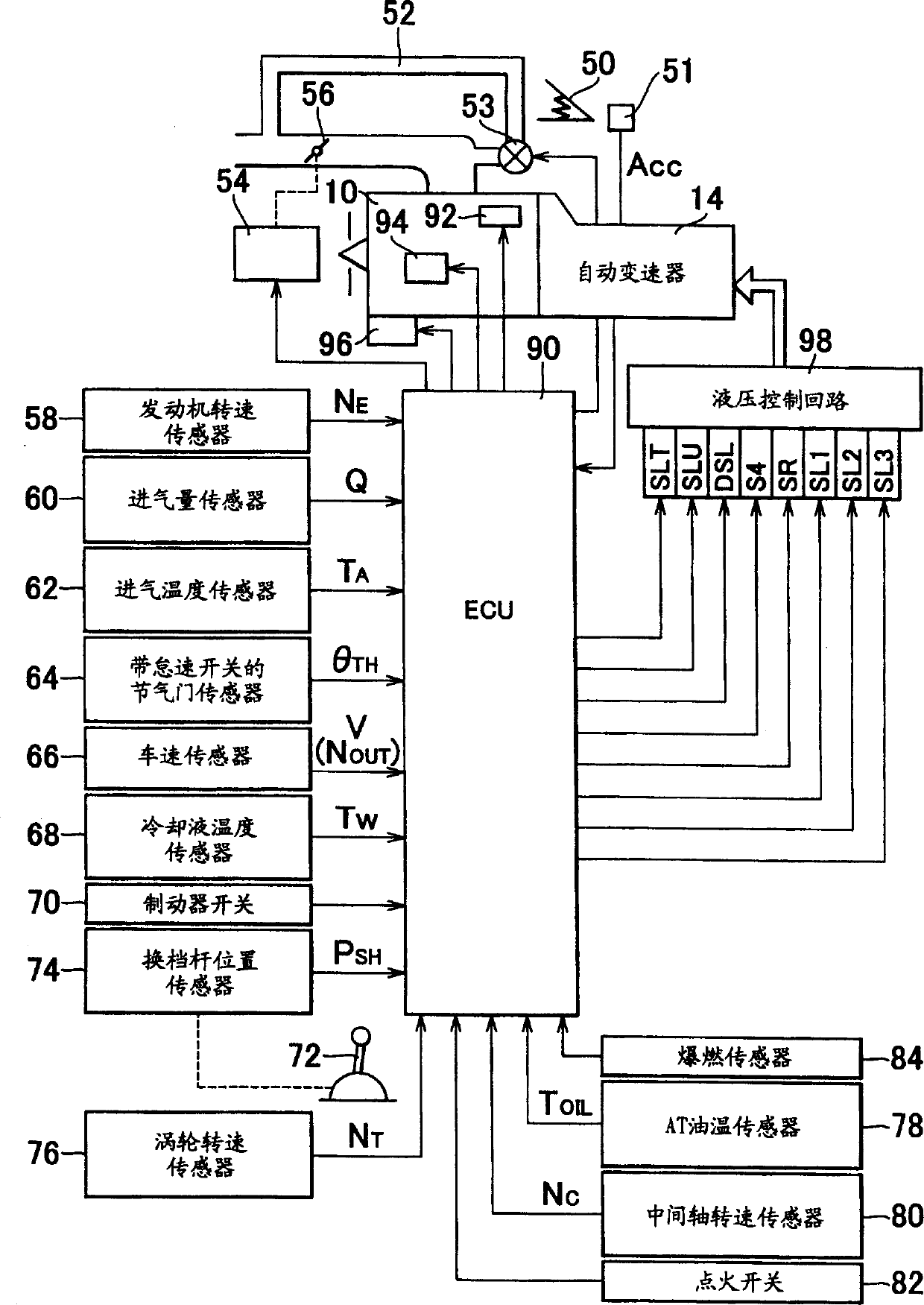

[0041]FIG. 1 is a schematic diagram of a transverse vehicle drive device of a vehicle such as a FF (Front Engine Front Drive) vehicle. One is an internal combustion engine such as a gasoline engine, and the output of the engine 10 is transmitted to the drive wheels (front wheels) through a power transmission device such as a torque converter 12, an automatic transmission 14 and a differential gear device (differential) 16. The torque converter 12 includes a pump wheel 20 connected to the crankshaft 18 of the engine 10, a turbine 24 connected to the input shaft 22 of the automatic transmission 14, and fixed on a housing 28 as a non-rotating member via a one-way clutch 26. The stator 30 and the lock-up clutch 32 directly connect the crankshaft 18 and the input shaft 22 via a buffer (not shown). A mechanical oil pump 21 such as a gear pump is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com