An avalanche photodiode

A technology of avalanche photodiodes and diodes, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as the inability to take into account the linearity and responsivity performance of avalanche photodiodes, achieve both linearity and responsivity performance, and increase transit time , The effect of reducing the amount of electric field drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

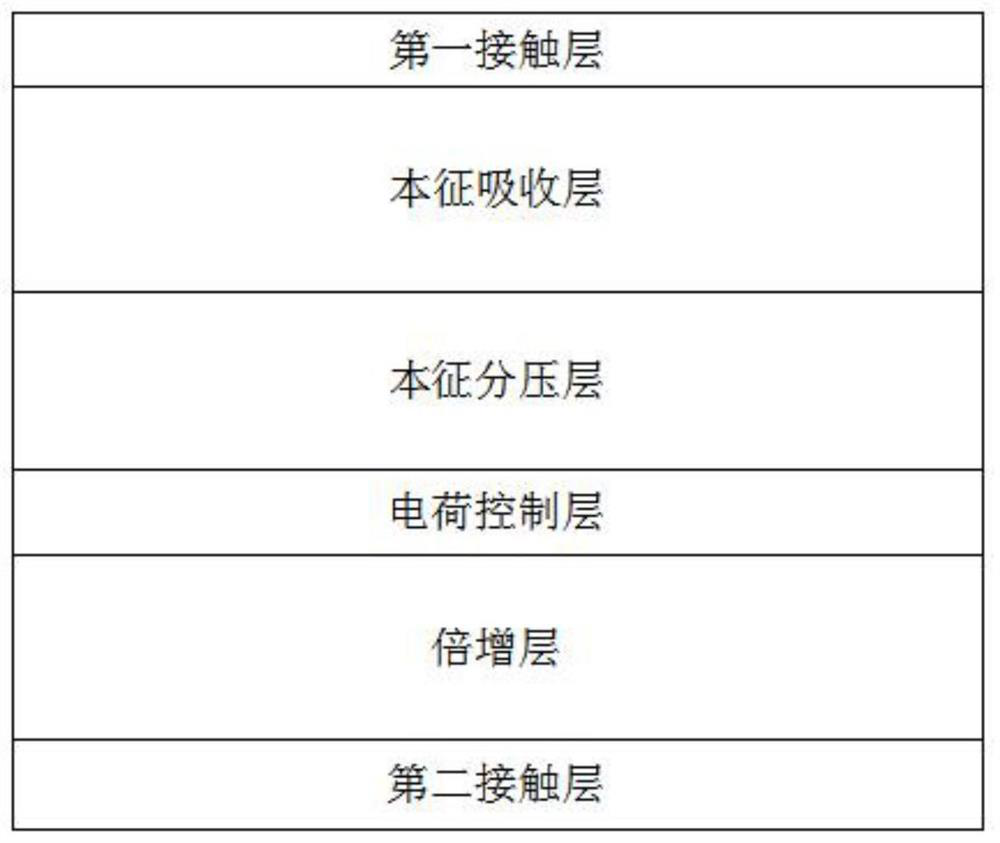

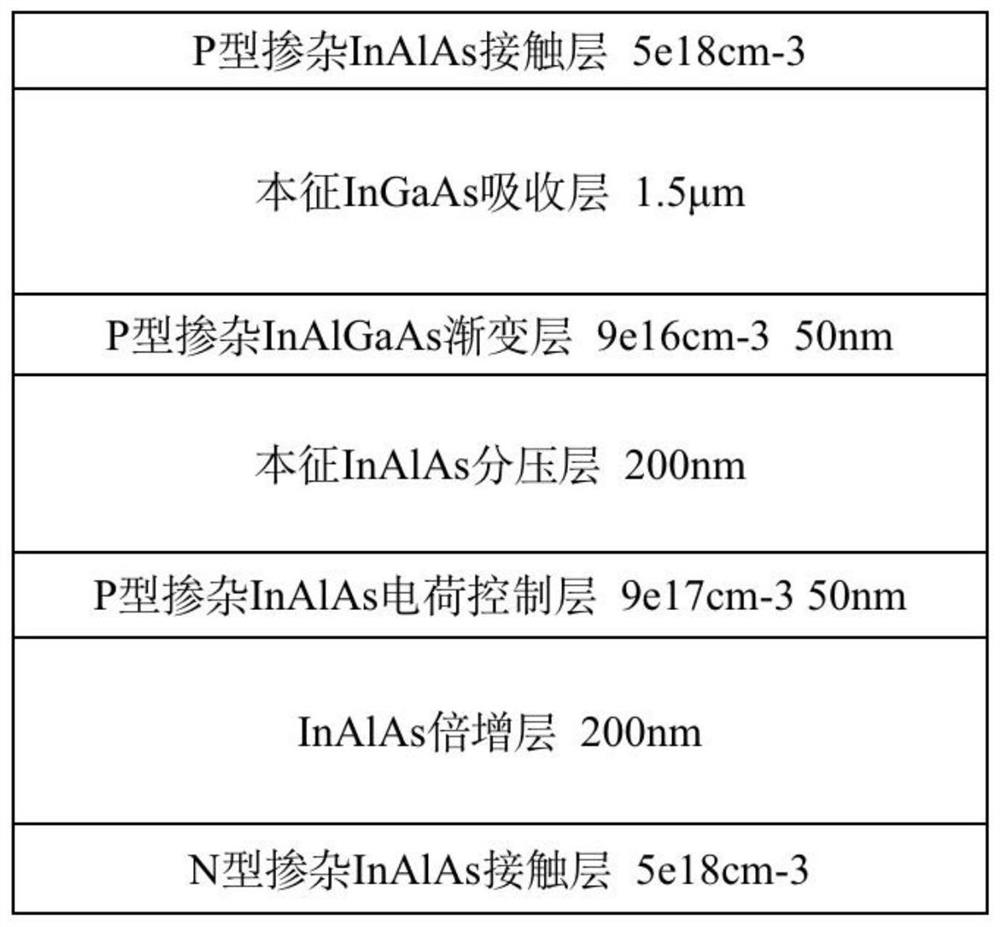

[0041] Take the III-V avalanche photodiode as an example for illustration, such as figure 2 As shown, it includes: P-type doped InAlAs contact layer, intrinsic InGaAs absorption layer, P-type doped InAlGaAs gradient layer, intrinsic InAlAs pressure dividing layer, P-type doped InAlAs charge control layer, InAlAs multiplication layer and N-type doped InAlAs contact layer;

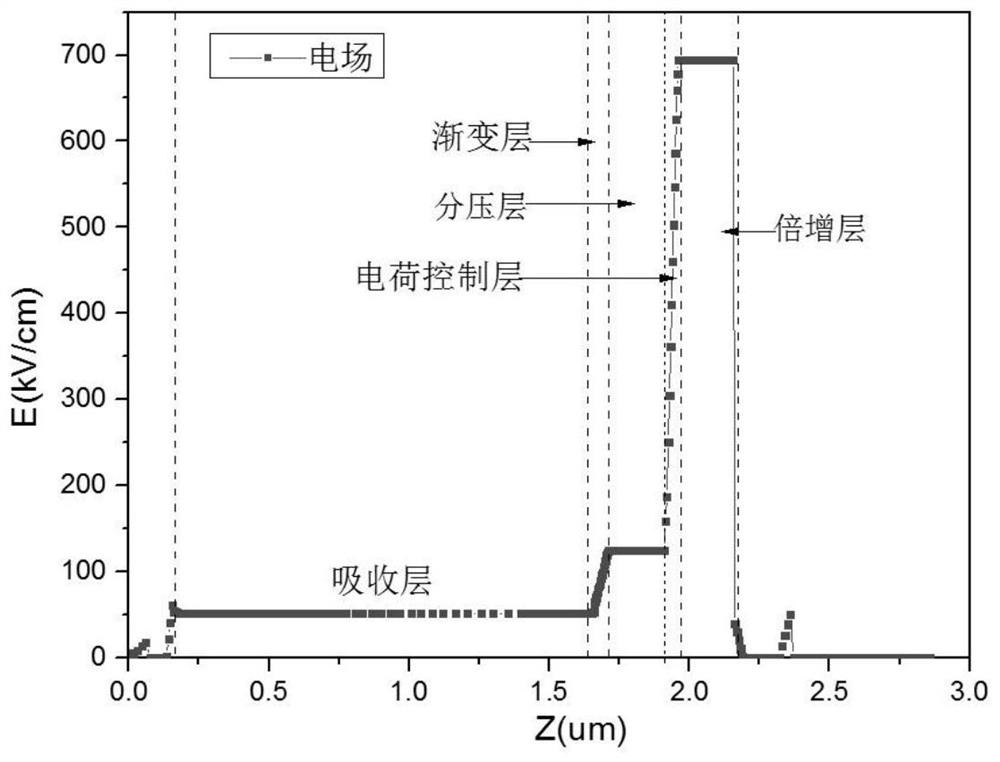

[0042] Wherein, the P-type doped InAlAs contact layer is used to connect with the P-type electrode. The intrinsic InGaAs absorbing layer is used to absorb incident light to form electron-hole pairs; in this embodiment, the incident light is in the near-infrared band. The P-type doped InAlGaAs graded layer is used to slow down the energy band discontinuity between the intrinsic InGaAs absorption layer and the intrinsic InAlAs pressure dividing layer. The intrinsic InAlAs voltage divider is used to increase the thickness of the avalanche photodiode based on the relationship between the potential and the ele...

Embodiment 2

[0050] Taking silicon germanium avalanche photodiode as an example, as Figure 5As shown, including: P-type doped Si contact layer, intrinsically doped Ge absorbing layer, intrinsically doped Si voltage divider layer, P-type doped Si charge control layer, intrinsically doped Si multiplier layer and N-type doped Si contact layer. Compared with the III-V avalanche photodiode diode, the SiGe avalanche photodiode has no graded layer, and the intrinsically doped Si voltage divider layer is placed between the intrinsically doped Ge absorption layer and the P-type doped Si charge control layer. The function of each layer of the silicon germanium avalanche photodiode is similar to that of the III-V avalanche photodiode, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com