Interconnection structure of electric conductive wirings

A technology of conductive wiring and construction, applied in conductive connection, structural connection of printed circuit, connection of electrical components, etc., can solve problems such as adhesive flow obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

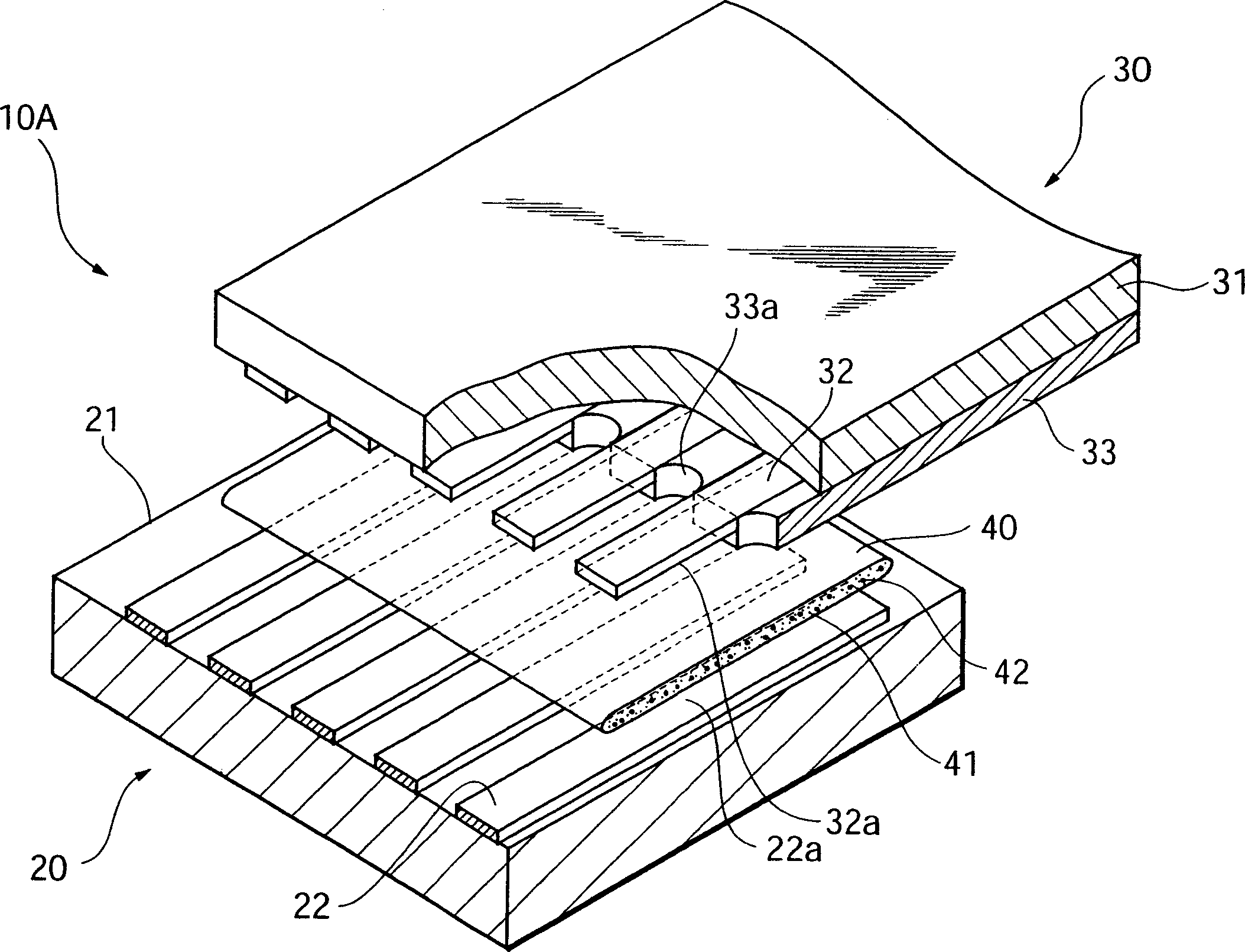

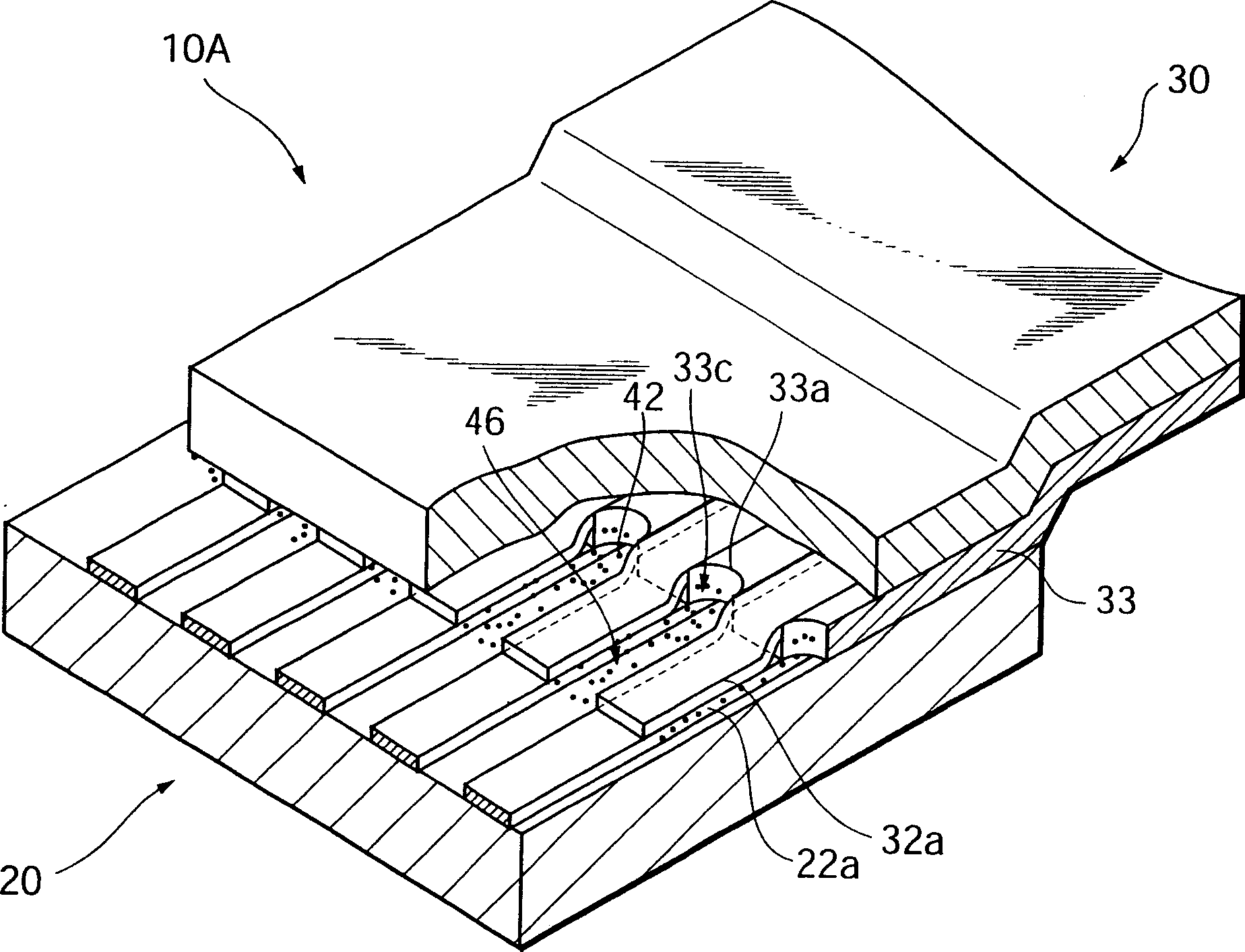

[0057] Next, an example in which a pair of connection partners of the above-mentioned embodiment is connected to an organic EL display panel and a flexible printed circuit board will be described.

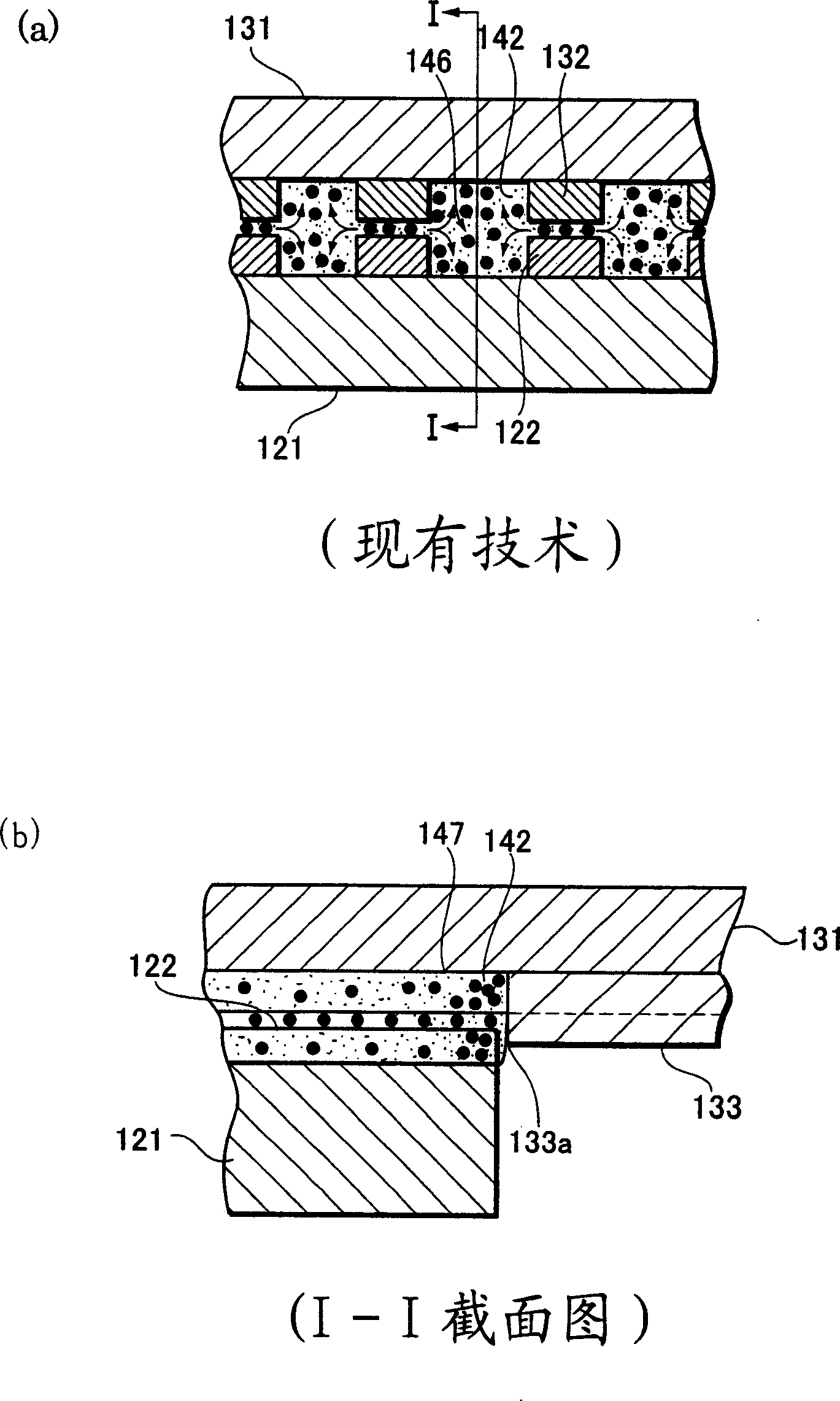

[0058] The organic EL display panel in this embodiment has a connection portion in which a wiring pattern of conductive wiring is formed on the surface of the substrate, and the connection object is thermocompression-bonded to the connection portion through an anisotropic conductive film. It is characterized in that recesses or cavities that allow conductive particles (moved by thermocompression) to stay are formed in gaps between wiring patterns on the surface of the substrate in the connecting portion.

[0059] According to the above-mentioned organic EL display panel, when other connection objects are connected to the above-mentioned connection part by thermocompression bonding, even the conductive particles of the anisotropic conductive film that move due to the pressure bonding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com