Driving apparatus for high acceleration revolution axis and application method thereof

A technology of acceleration and rotating shaft, applied in electromechanical devices, assembly machines, metal processing, etc., can solve problems such as mold or component damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

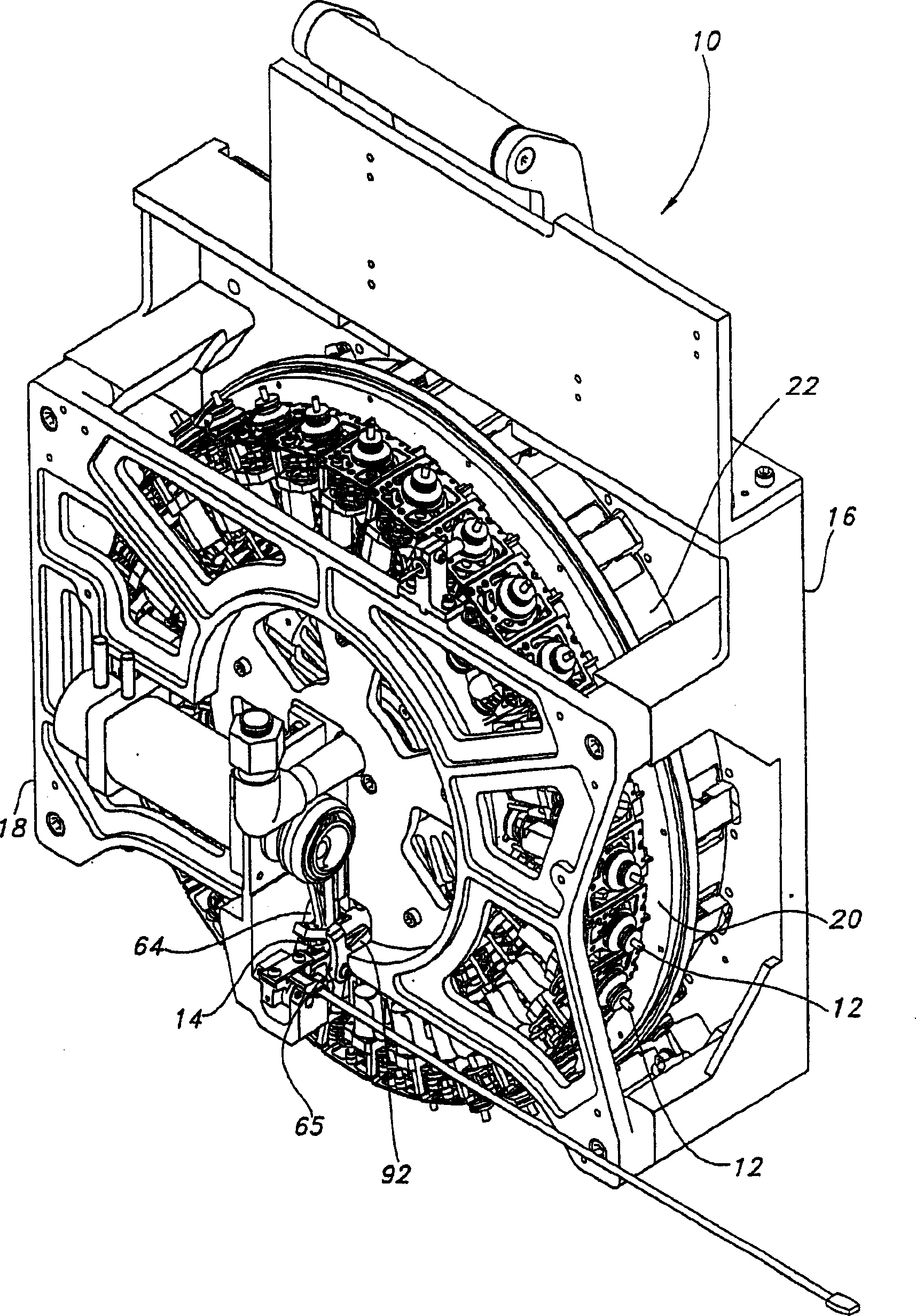

[0018] figure 1 Shown is a perspective view of a pick and place device 10 according to a preferred embodiment of the present invention. The pick and place device 10 can be used in pick and place equipment to pick up electronic components and place them at desired locations during assembly operations.

[0019] The pick and place device 10 includes a rear portion 16 of the pick and place device frame, and a front portion 18 of the pick and place device frame. A pivot support 20 is arranged between the front part 18 and the rear part 16 of the pick-and-place device support.

[0020] Spindle support 20 includes a plurality of pick and place heads 12 mounted thereon. A motor 22 is arranged in the device to drive the spindle support 20 relative to the pick and place device supports 16 , 18 .

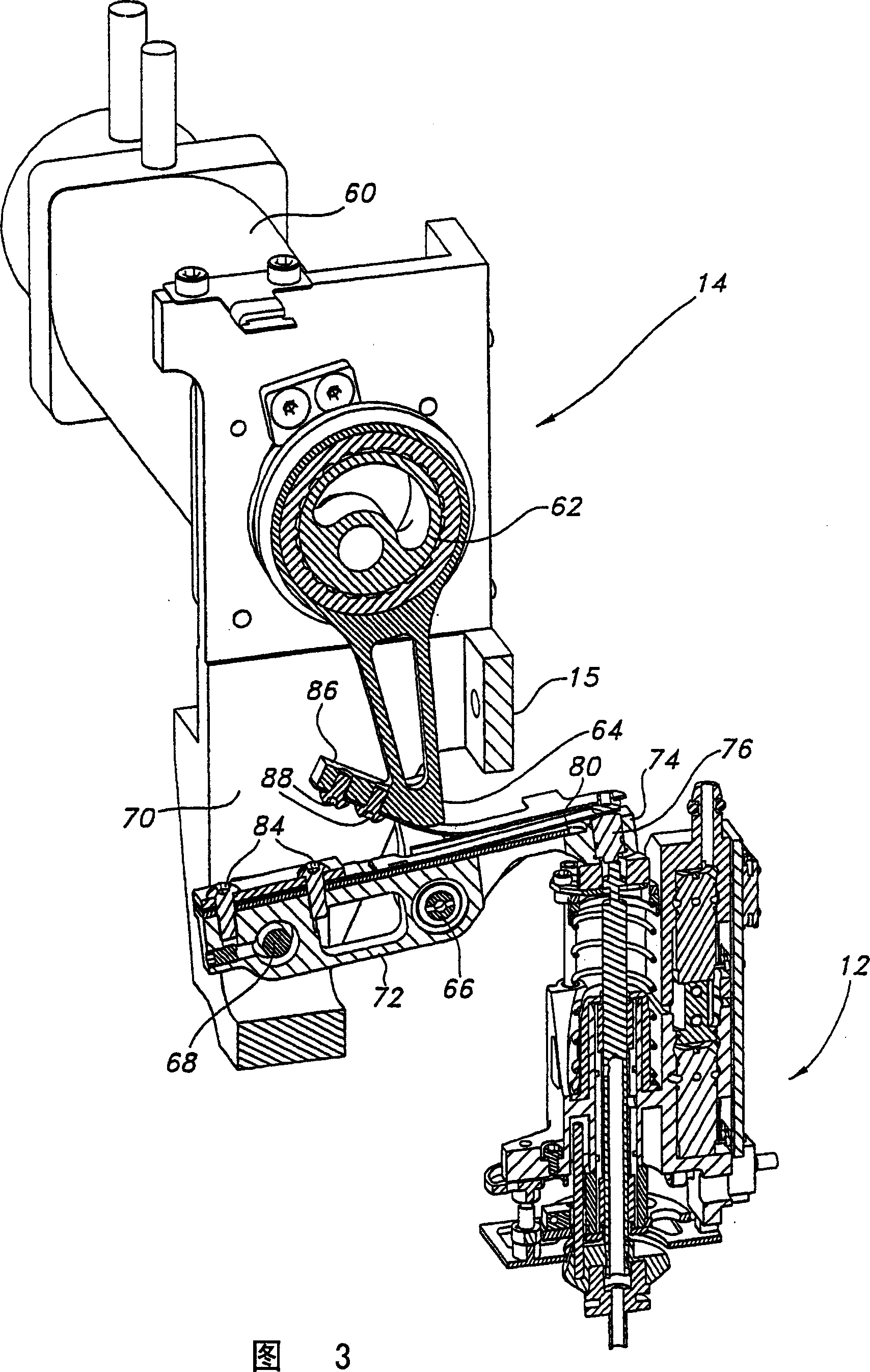

[0021] At the front part of the pick-and-place device 10 a spindle drive assembly 14 is arranged. 3-5 show detailed views of the spindle drive assembly 14 .

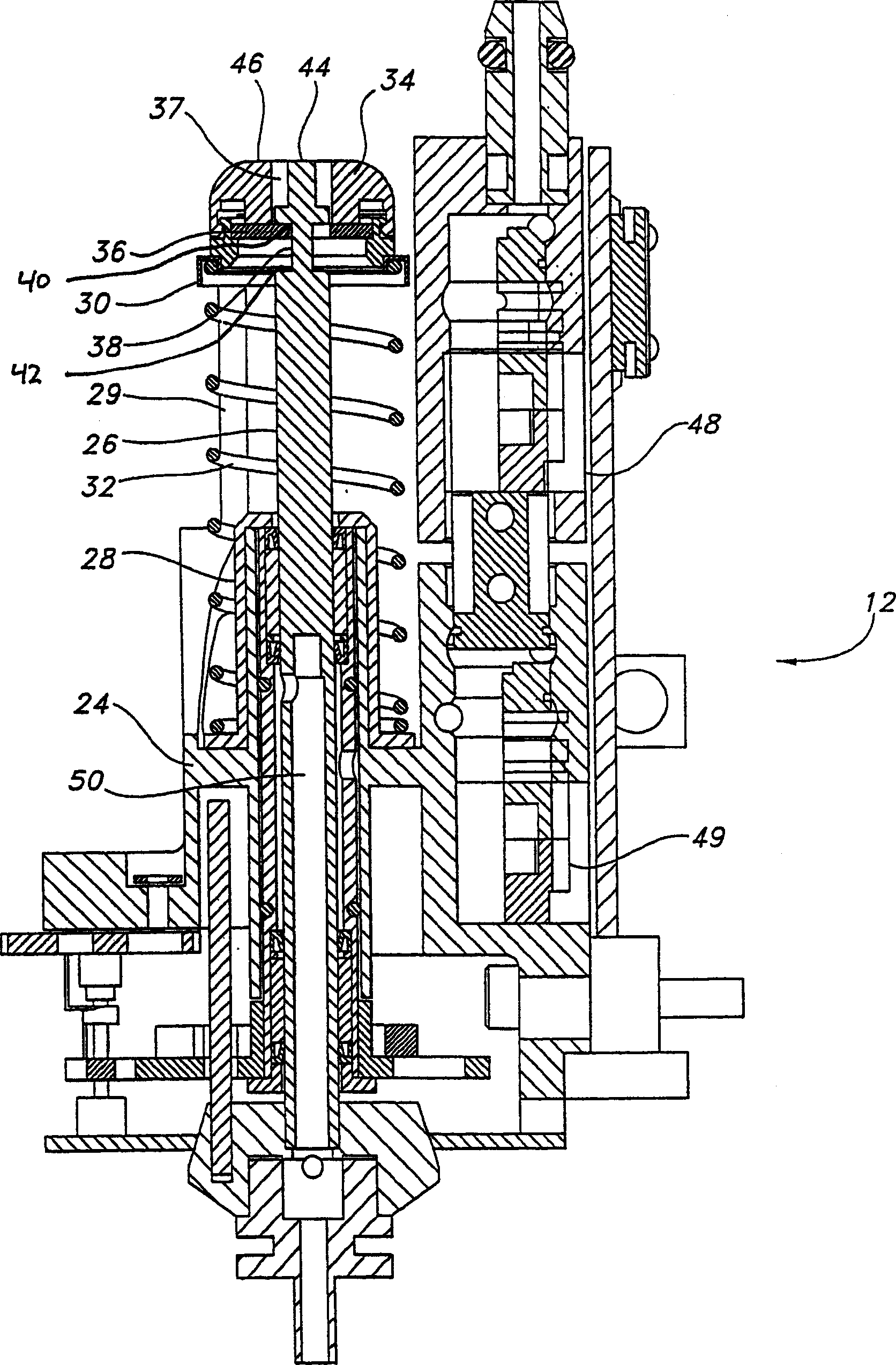

[0022] Figure 2-5 A pick a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap