Making process of dog's chewing made of mixed pig and ox skin

A processing method, the technology of dog chews, is applied in the field of leather pet food processing, which can solve the problems of single leather material and the advantages of single leather material, and achieve the effects of prolonging chewing time, increasing chewing and eating interest, and strong fiber toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

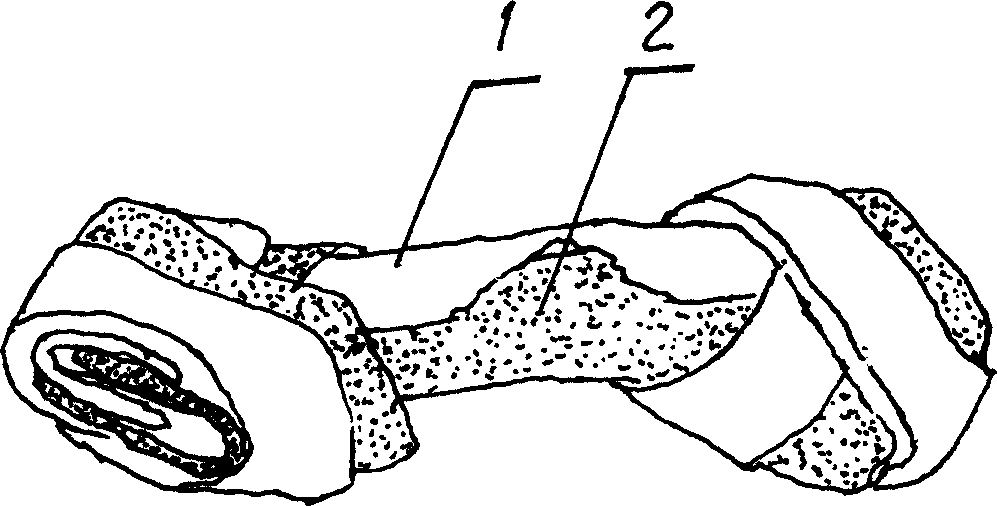

[0026] Embodiment 1: as figure 1 As shown, after deashing, cleaning, degreasing and hydrogen peroxide disinfection, the two-layer leather of cowhide and pigskin becomes the raw material leather, which is cut into rectangular block-shaped raw leather according to the size of the knotted bone dog chew product. . Smoking the block-shaped embryo skin of pigskin to reddish-brown according to the existing process, then immersing it in normal temperature water to soften it, taking it out after 2 hours of water immersion and draining. Combining the softened cowhide skin 1 and the softened pigskin skin 2 (the blackened part in the figure) into an overlapping body that reveals the two skins, the specific method is to combine block cowhide, pig The leather embryos are folded and plugged into flat bodies, and knotted at both ends of the flat bodies to form knotted bone dog chew semi-finished products, which are then dried according to the existing process conditions. figure 1 Pig and co...

Embodiment 2

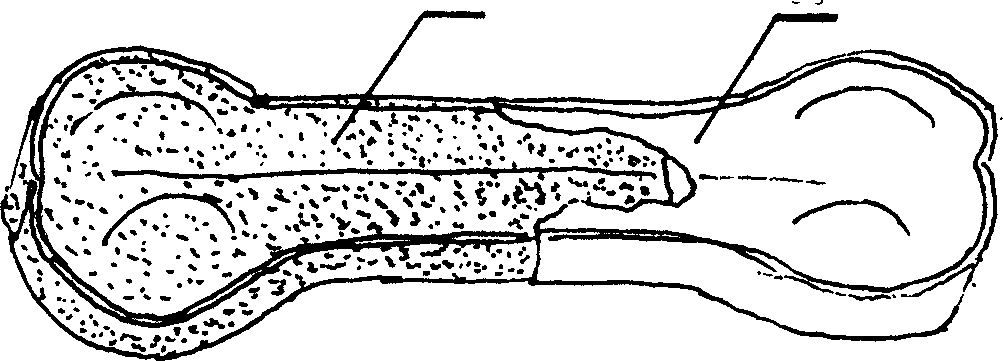

[0027] Embodiment 2: as figure 2 As shown, the processing method of the cowhide and pigskin raw hides is the same as that in Example 1, and the leather-pressed bone dog chew products are cut into block-shaped embryo hides according to the size of the leather-pressed bone dog chew products. The smoked coloring and softening treatment method of the pigskin raw material skin is the same as that in Example 1. Combining the softened raw cowhide skin 1 and the softened pigskin raw skin 2 (the blackened part in the figure) into an overlapping body that reveals the two raw skins, the specific method is block cowhide and pigskin The blank skins are folded and inserted into each other, and the middle is filled with cowhide and pigskin blank skins to form a layered body, and the layered body is molded into a semi-finished product of leather-pressed bone dog chew. Then dry according to the existing process conditions figure 2 Pig and cowhide mixed leather and bone dog chews.

Embodiment 3

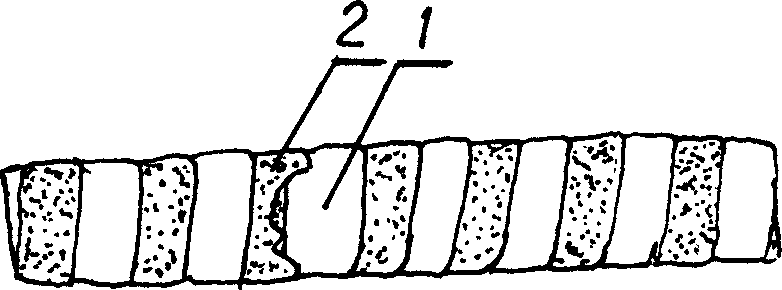

[0028] Embodiment 3: as image 3 As shown, the cowhide and pigskin raw hides are treated in the same way as in Example 1, and then they are cut into strip-shaped embryo hides respectively. The smoked coloring and softening treatment method of pigskin strip-shaped blank skin is the same as that in Example 1. Combining the strip-shaped cowhide skin 1 that is still in the softened state and the softened pigskin skin 2 (the blackened part in the figure) are combined to reveal the overlap of the two types of skins. The specific method is to combine the strip-shaped cowhide The raw material of pigskin and pigskin is folded and connected to each other to form a strip-shaped flat body, and the strip-shaped flat body is spirally wound to form a semi-finished product of spiral skin rolled dog chew. Then dry according to the existing process conditions image 3 Spiral rolled dog chews mixed with pig and cowhide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com