Industrial method for preparing beta-ionone

A technology of ionone and pseudo-ionone, applied in the fields of medicine and chemical industry, can solve problems such as difficulty and achieve the effect of preventing local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

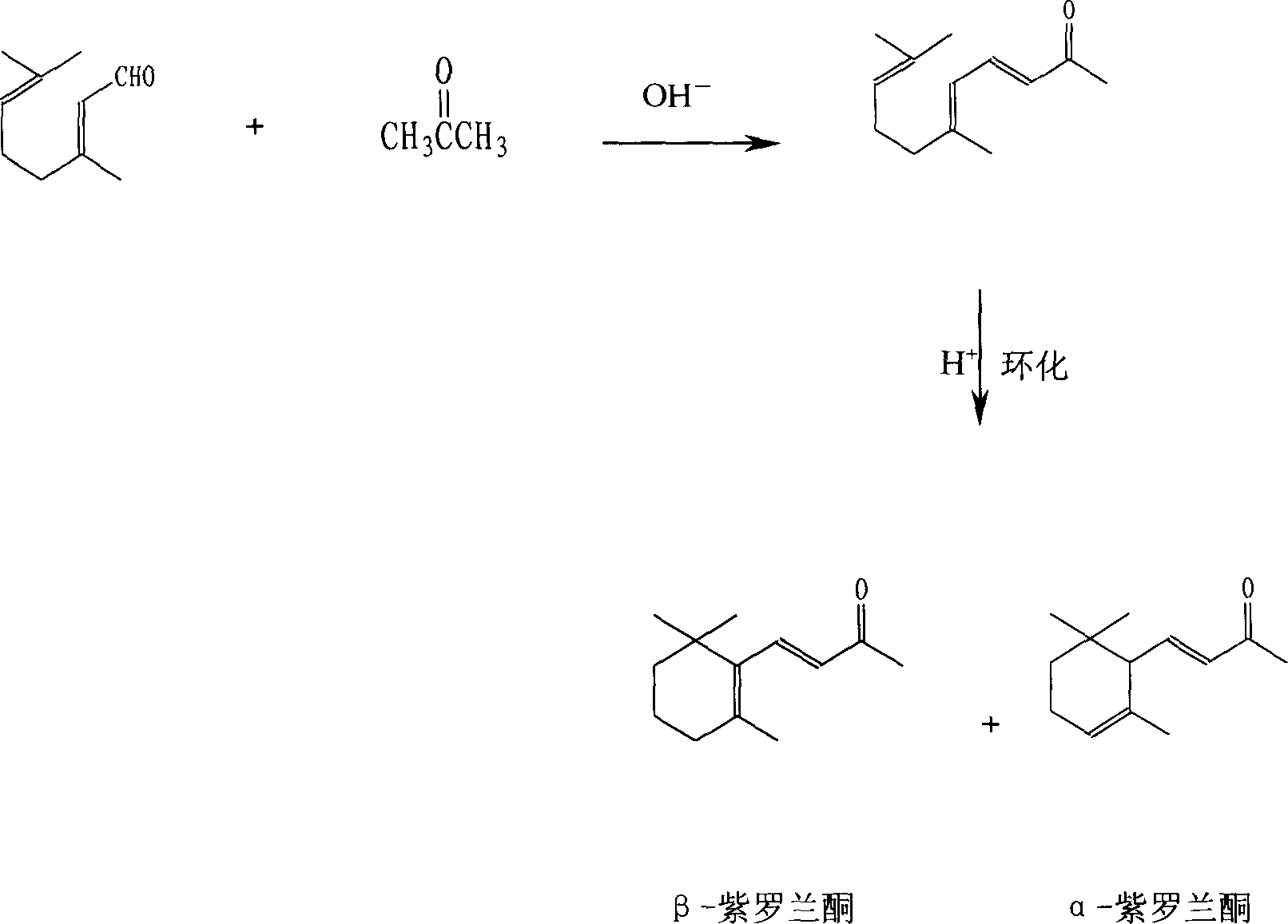

Method used

Image

Examples

Embodiment 1

[0013] Add 1100 liters of acetone, 260 liters of water, and 25 liters of 30% NaOH solution into the reaction kettle, and stir evenly. At 20° C., 170 kg of citral (content ≥ 95.0%) was added dropwise within 2 hours. After the addition was complete, the reaction was continued for 2 to 4 hours, during which samples were taken for chromatographic analysis every half hour. When the conversion rate of citral is >99.0%, neutralize with acetic acid to PH = 6.0-6.5, let stand to separate layers, separate to remove the water layer, and collect and recover acetone. The organic layer was evaporated to remove the solvent to obtain the crude pseudoionone, and the fraction at 104-109°C / 240Pa was collected by vacuum distillation to obtain 201.3 kg of the finished pseudoionone with a content of 92.2% and a yield of 90.8%.

[0014] 120 liters of 6 # Solvent oil, 5 liters of methanol, 160 liters of concentrated sulfuric acid, stir evenly, cool to -18°C, add 55 kg of the above-mentioned pseudo-i...

Embodiment 2

[0017] Add 800 liters of acetone, 260 liters of water, and 25 liters of 30% NaOH solution into the reaction kettle, and stir evenly. At 28° C., 250 kilograms of litsea cubeba oil (containing citral 67.0%) was added dropwise while stirring within 2 hours. After the addition is complete, continue to react for 2 to 4 hours, during which every half hour, samples are taken for chromatographic analysis. When the conversion rate of citral is >95.0%, neutralize with acetic acid to PH = 6.5-7, let the layers stand, and separate the water layer (collect it separately and recover acetone). The organic layer was evaporated to remove the solvent to obtain the crude product of pseudo-ionone, and the fraction at 110-117°C / 525Pa was collected by vacuum distillation to obtain 197.4 kg of the finished pseudo-ionone with a content of 90.2% and a yield of 84.2%.

[0018] 120 liters of 6 # Solvent oil, 5 liters of methanol, 160 liters of concentrated sulfuric acid, stirred and cooled to -12~-18°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com