Method for calibrating structure optical vision sensor

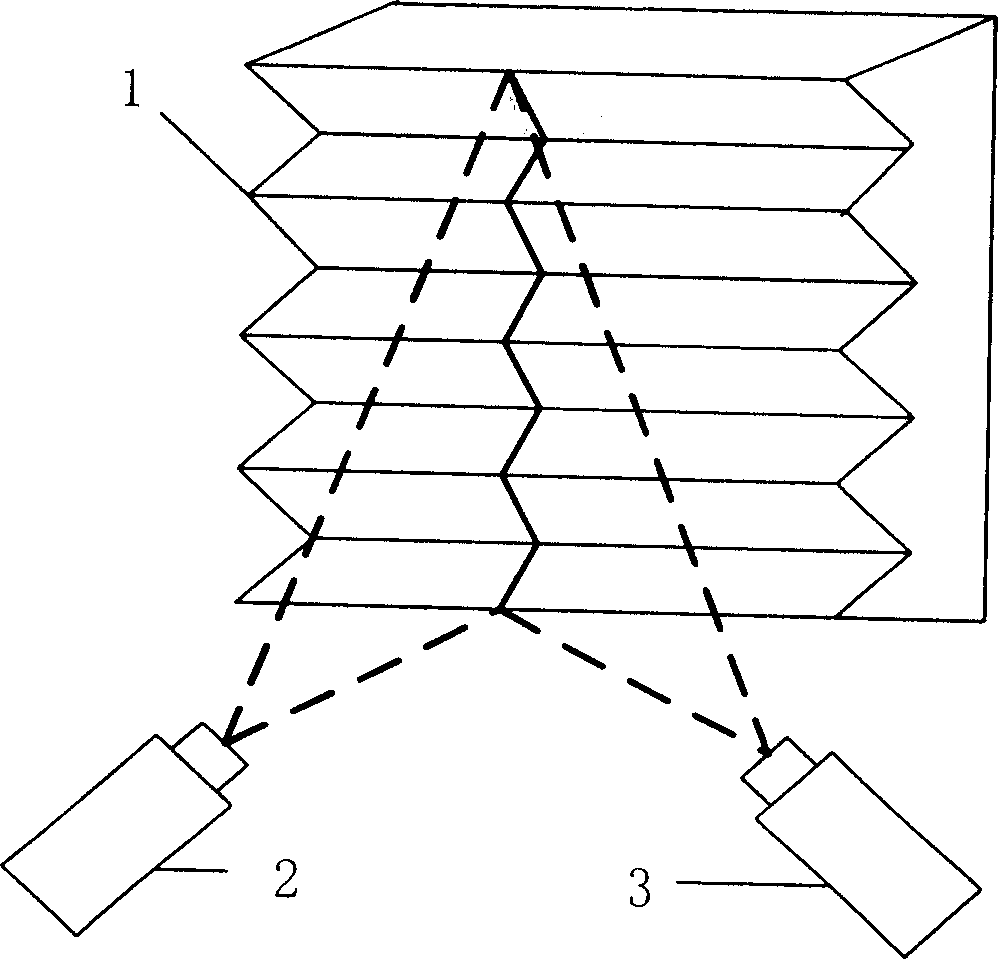

A visual sensor and calibration method technology, applied in the field of measurement, can solve the problems of a small number of calibration points, low image point extraction accuracy, easy reflection of teeth, etc., and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

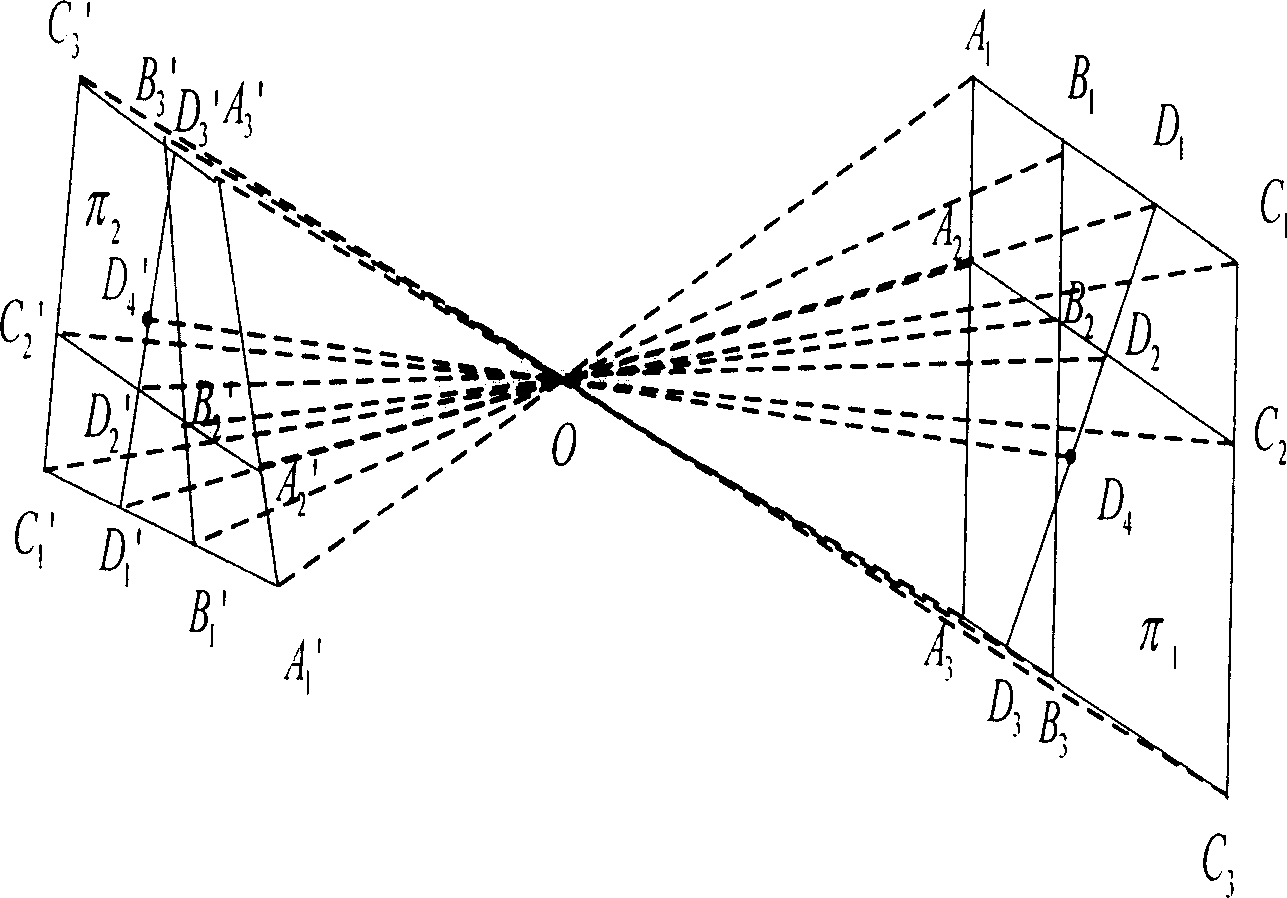

Method used

Image

Examples

Embodiment

[0056] The actual design of the structured light vision sensor is as follows: Image 6 shown. 10 is the housing of the sensor, 11 is the window for the CCD to observe the scene, and 12 is the exit port of the laser. The positions of CCD and laser in the sensor are different, and their parameters are also different.

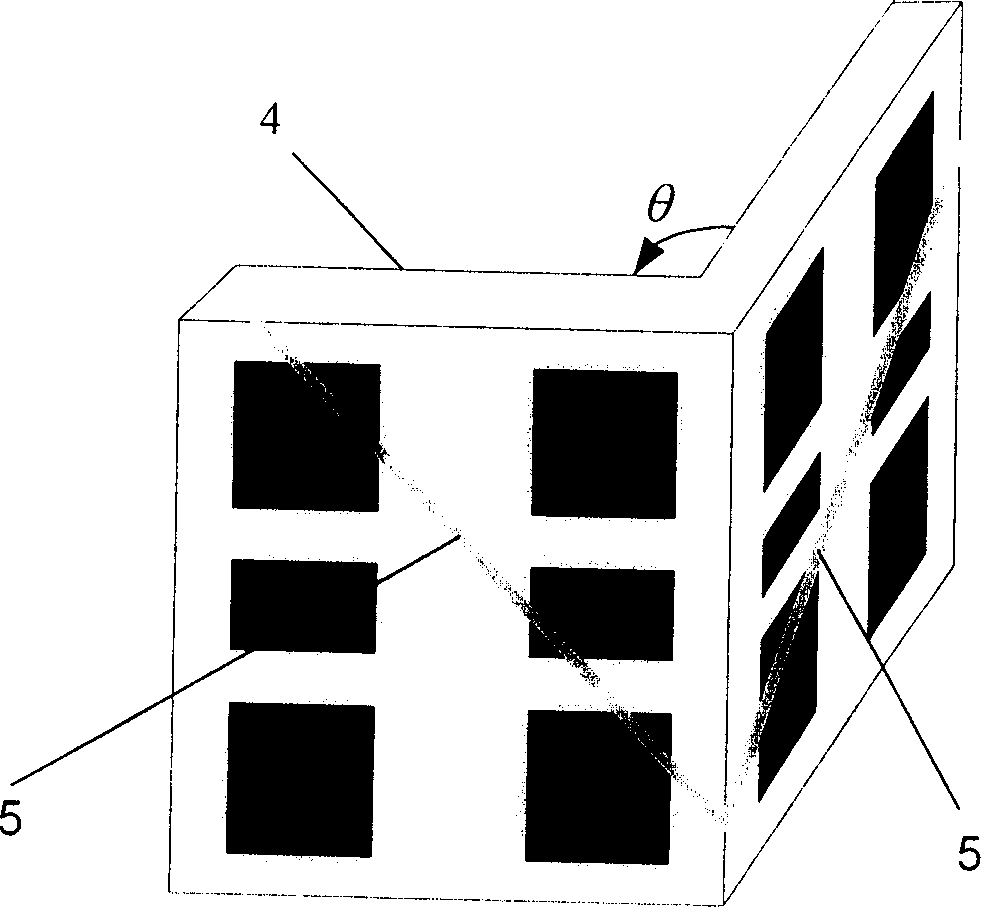

[0057] Following the steps described above, use the image 3 The targets shown (θ = 90°) were calibrated for three specific sensors.

[0058] Sensor one:

[0059] ·Camera perspective projection imaging model parameters

[0060] R = 0.135832 0.171788 0.975725 0.843045 - 0.537361 - 0.022753 0.520408 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com