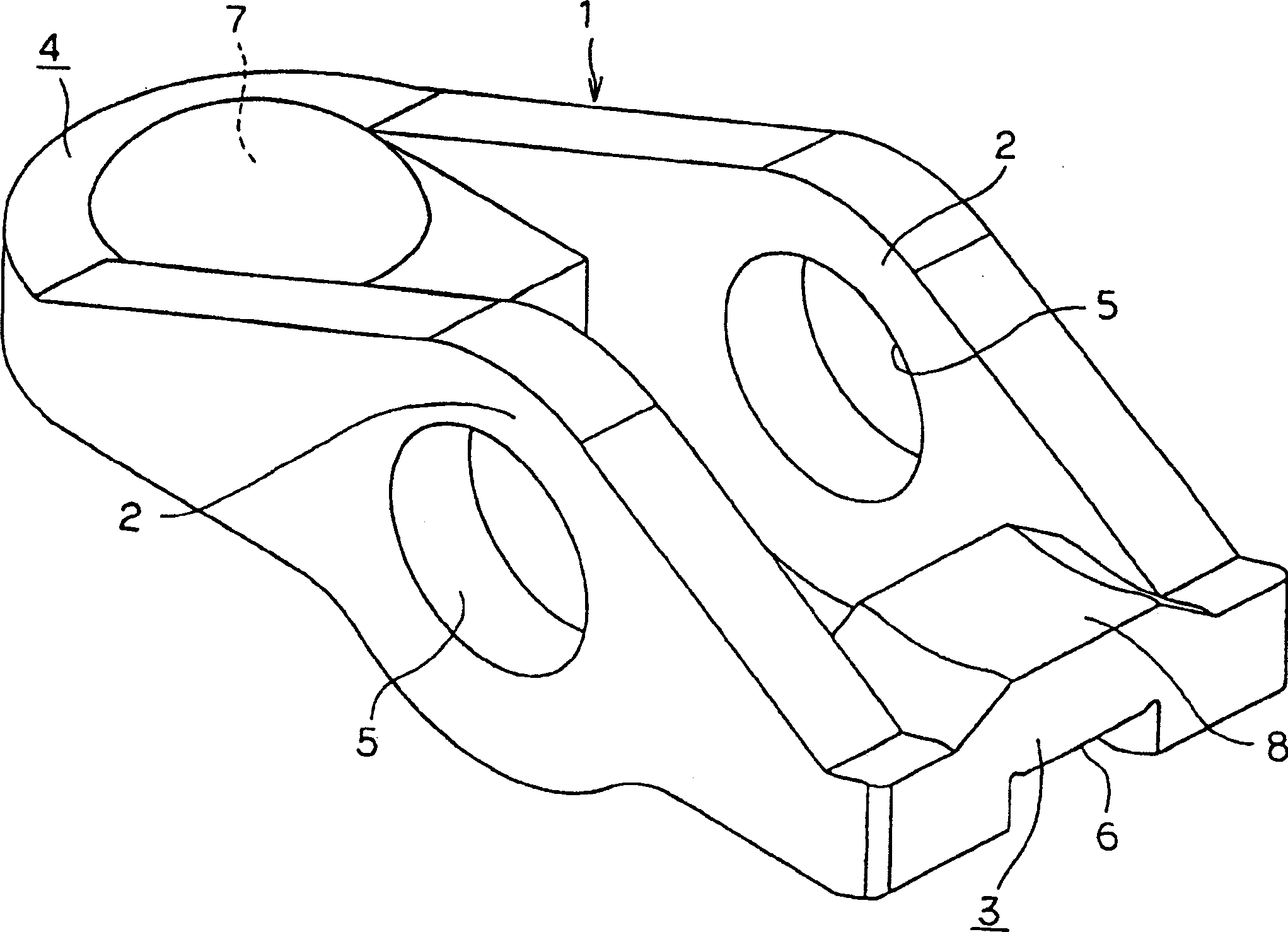

Metal plate rocker arm and method of manufacturing same

A manufacturing method, sheet metal technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., to achieve low cost, high quality, and the effect of suppressing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

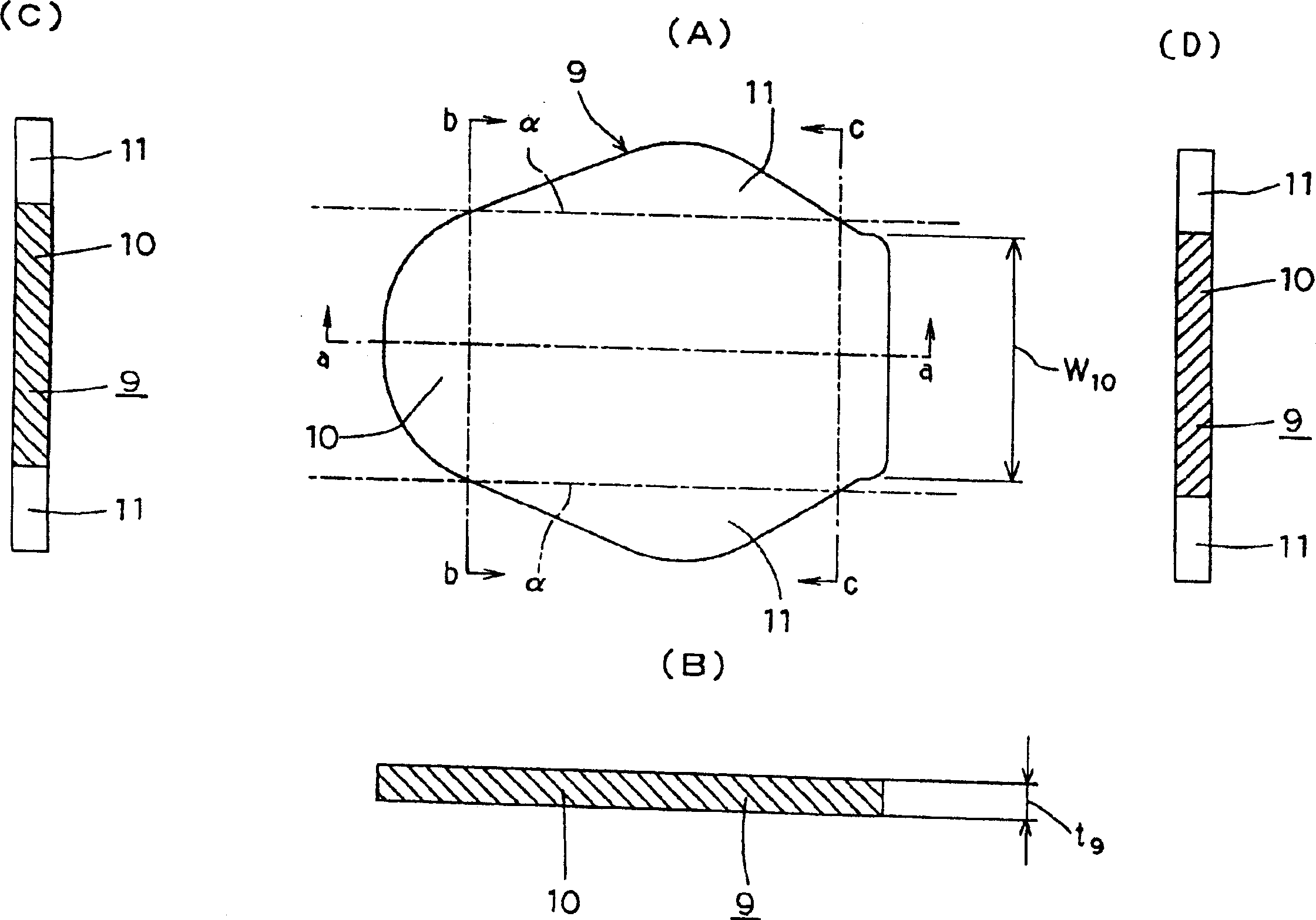

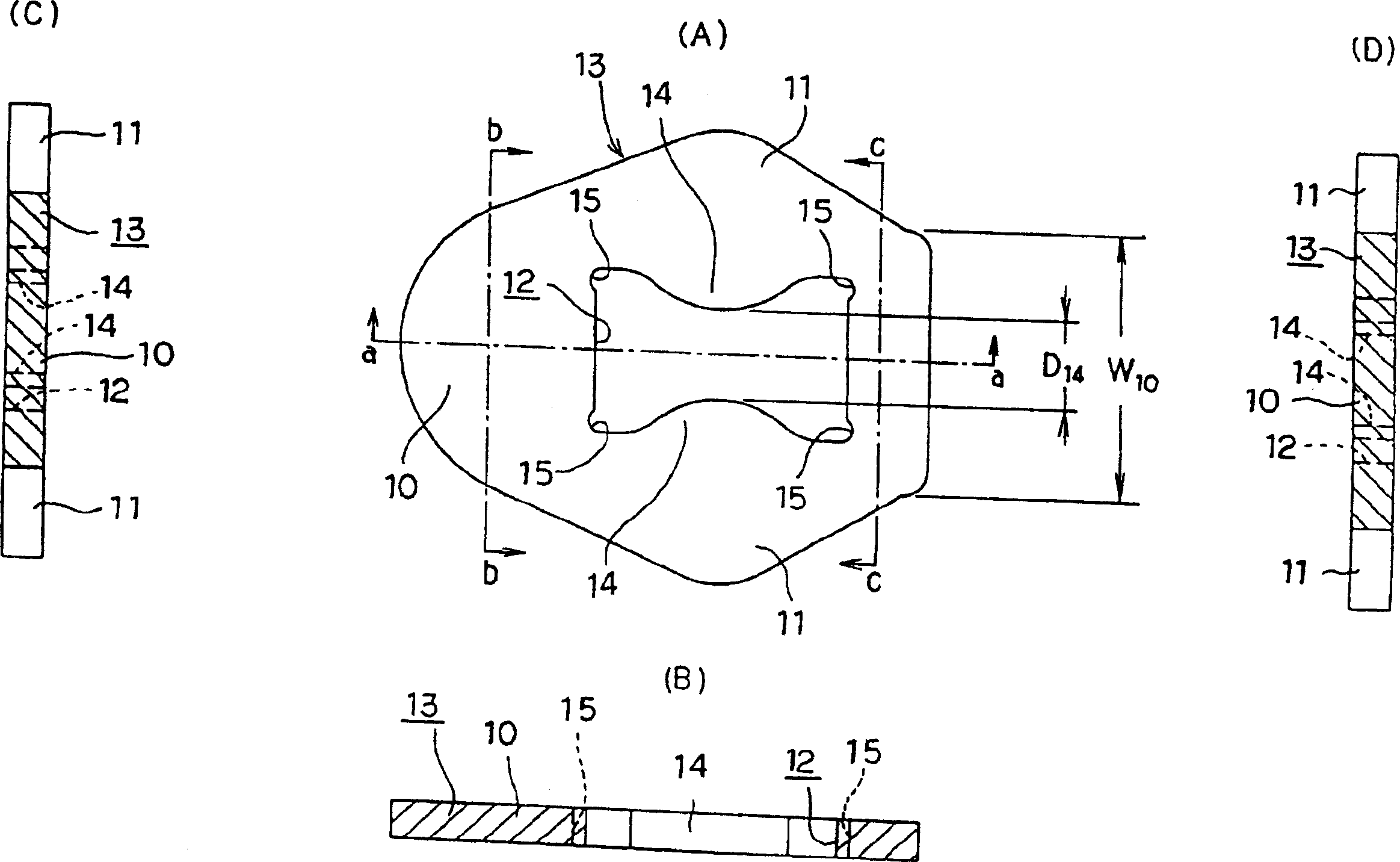

[0075] Figures 9 to 10 show a first example of an embodiment of a rocker arm made of sheet metal of the present invention. In addition, the present invention is characterized in that even on the mating portion 6 provided on one side of the connecting portion 3 (lower surface of FIGS. 9 to 10), the return spring that urges the valve body abutting the base end When the elastic force becomes larger and the force applied to the mating portion 6 becomes greater, in order to ensure sufficient durability of the connecting portion 3, and to increase the strength of the mating portion 6, the cross-sectional shape of the connecting portion 3 is up and down effort. The structure of the other parts of the rocker arm 1 made of sheet metal is the same as in the case of the above-mentioned previous invention, and the same parts are marked with the same symbols. Therefore, the repeated description is omitted or simplified. Hereinafter, the characteristic parts of the present invention are centere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com