Heat-pump water heater

A hot water supply, heat pump technology, applied in residential hot water supply systems, heat pumps, heating methods, etc., can solve problems such as difficulty in coping with a wide range of hot water supply loads, reducing efficiency, and increasing the temperature of hot water supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

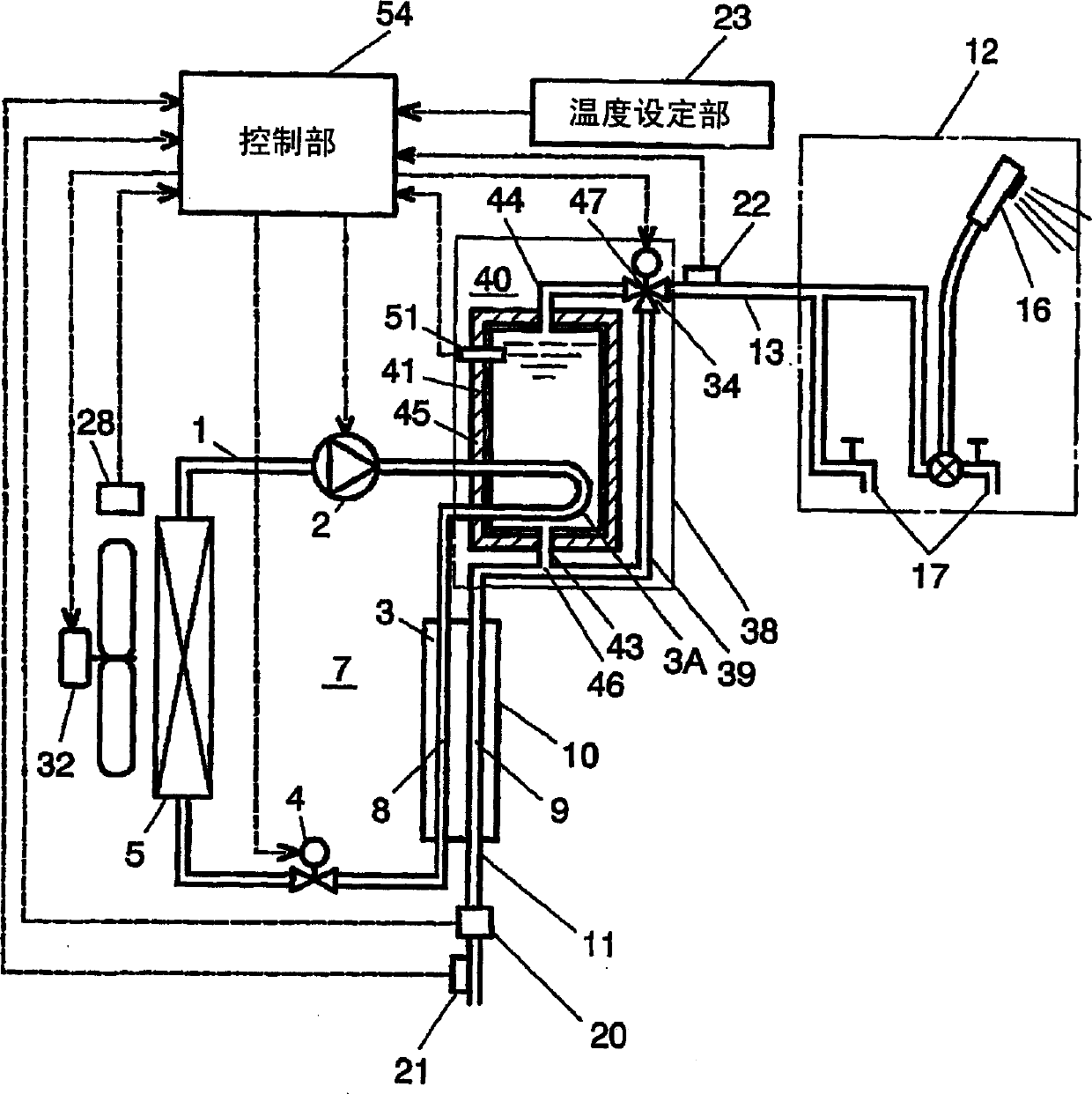

[0031] Fig. 1 is a block diagram of a heat pump hot water supply device according to a first embodiment of the present invention. In FIG. 1 , in the heat pump cycle mechanism 7 , the compressor 2 , the first radiator 3A, the second radiator 3 , the decompression unit 4 and the heat absorber 5 are connected to form a closed circuit through the refrigerant flow path 1 . . The heat pump cycle mechanism 7 is a supercritical heat pump cycle mechanism that uses, for example, carbon dioxide gas as a refrigerant, and the refrigerant pressure on the high-pressure side is equal to or higher than the critical pressure of the refrigerant. The compressor 2 is driven by a built-in electric motor (not shown), and compresses the drawn refrigerant to a critical pressure and discharges it. In addition, the heat exchanger 10 has a water flow path 9 that exchanges heat with the refrigerant flow path 8 of the second heat radiator 3 . The water supply pipe 11 that directly supplies tap water to t...

no. 2 Embodiment

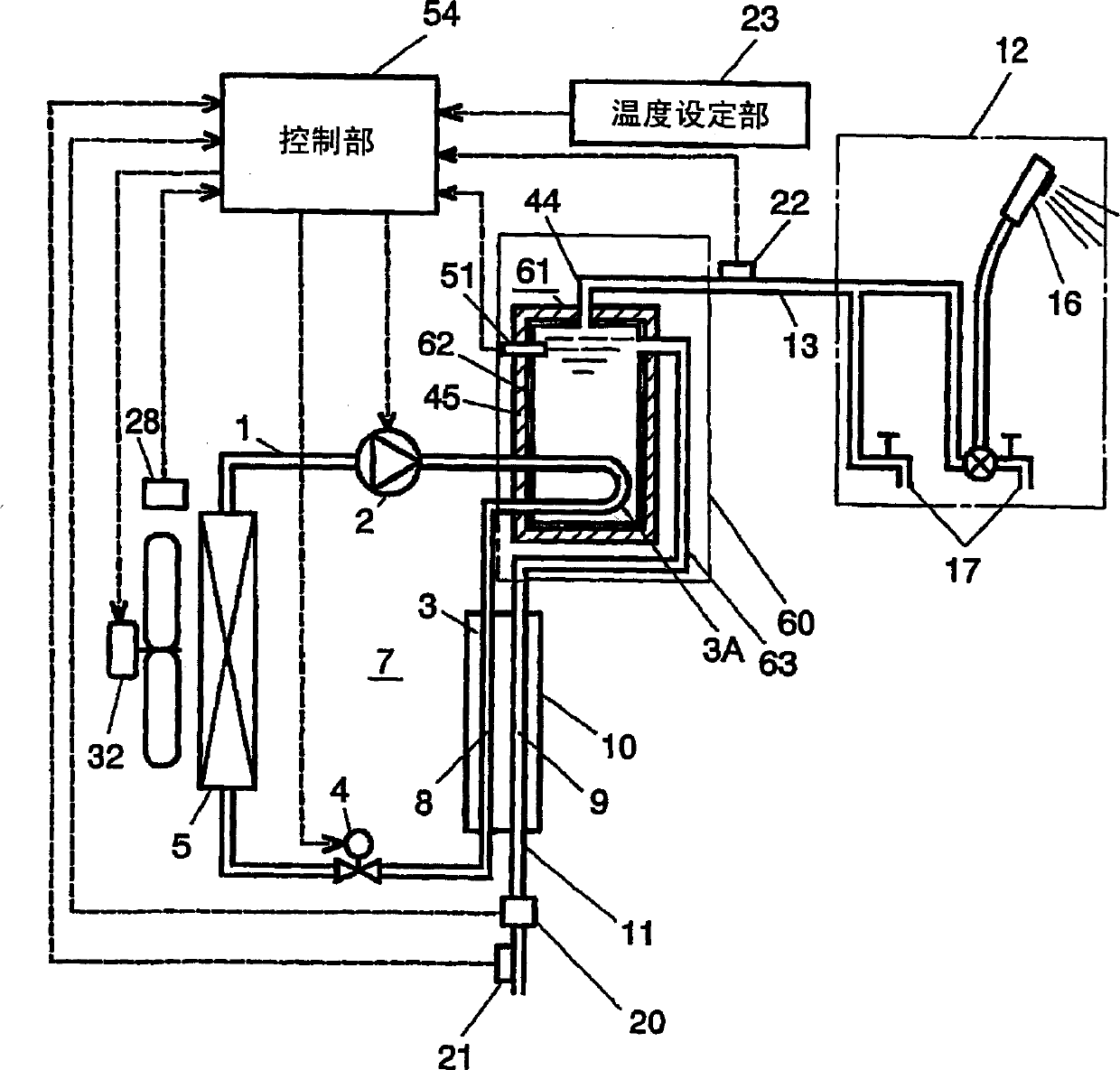

[0049] Fig. 2 is a block diagram of a heat pump hot water supply device according to a second embodiment of the present invention. In FIG. 2 , the difference from the configuration of the first embodiment is that a heating unit 60 is provided instead of the heating unit 38 . The heating unit 60 is provided with a heat storage unit 61 aligned with the hot water supply circuit 13 . Another difference is that in the heat storage part 61 , the inlet pipe 63 is arranged on the upper part of the storage tank 62 and the hot water in the storage tank 62 and the water (hot water) from the heat exchanger are mixed inside the storage tank 62 . And the storage temperature when the storage tank 62 performs a heat-retaining operation is set to the same temperature as the target temperature (for example, 45 degreeC) of hot water supply. However, if the storage temperature is low, the storage tank 62 has a large capacity.

[0050] In the above structure, if the heat exchanger 10 starts to s...

no. 3 Embodiment

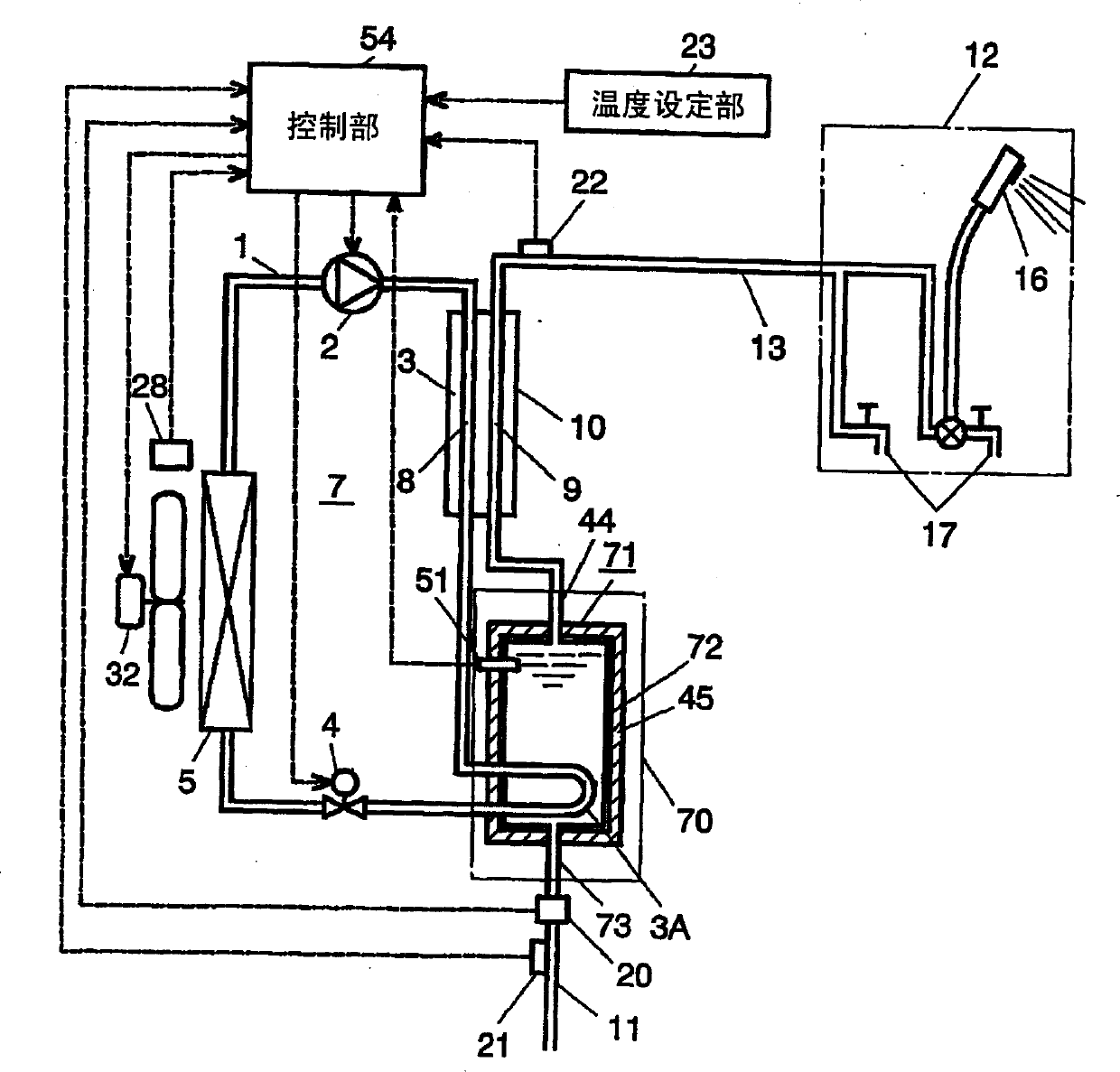

[0053]Fig. 3 is a block diagram of a heat pump hot water supply device according to a third embodiment of the present invention. In FIG. 3 , the difference from the configuration of the second embodiment is that a heating unit 70 is provided instead of the heating unit 60 . The heating unit 70 is provided with a heat storage unit 71 aligned with the water supply pipe 11 . Another difference is that an inlet pipe 73 is arranged at the bottom of the storage tank 72 of the heat storage unit 71 . And the storage temperature when the storage tank 72 performs a heat-retaining operation is set to the same temperature as the target temperature (for example, 45 degreeC) of hot water supply.

[0054] In the above structure, if the hot water is supplied from the completely cooled state of the heat exchanger 10 , the cold water will flow into the bottom of the storage tank 72 from the water supply pipe 11 , and the warm water in the storage tank 72 will flow out from the outlet pipe 44 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com