Module device of LED point matrix display

A display and dot matrix technology, which is applied in the field of module devices, can solve the problems affecting the service life of LED dot matrix displays, changing the characteristics of crystal grains, and weakening the brightness of LEDs, so as to improve heat dissipation, shorten the dot pitch, and increase resolution. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

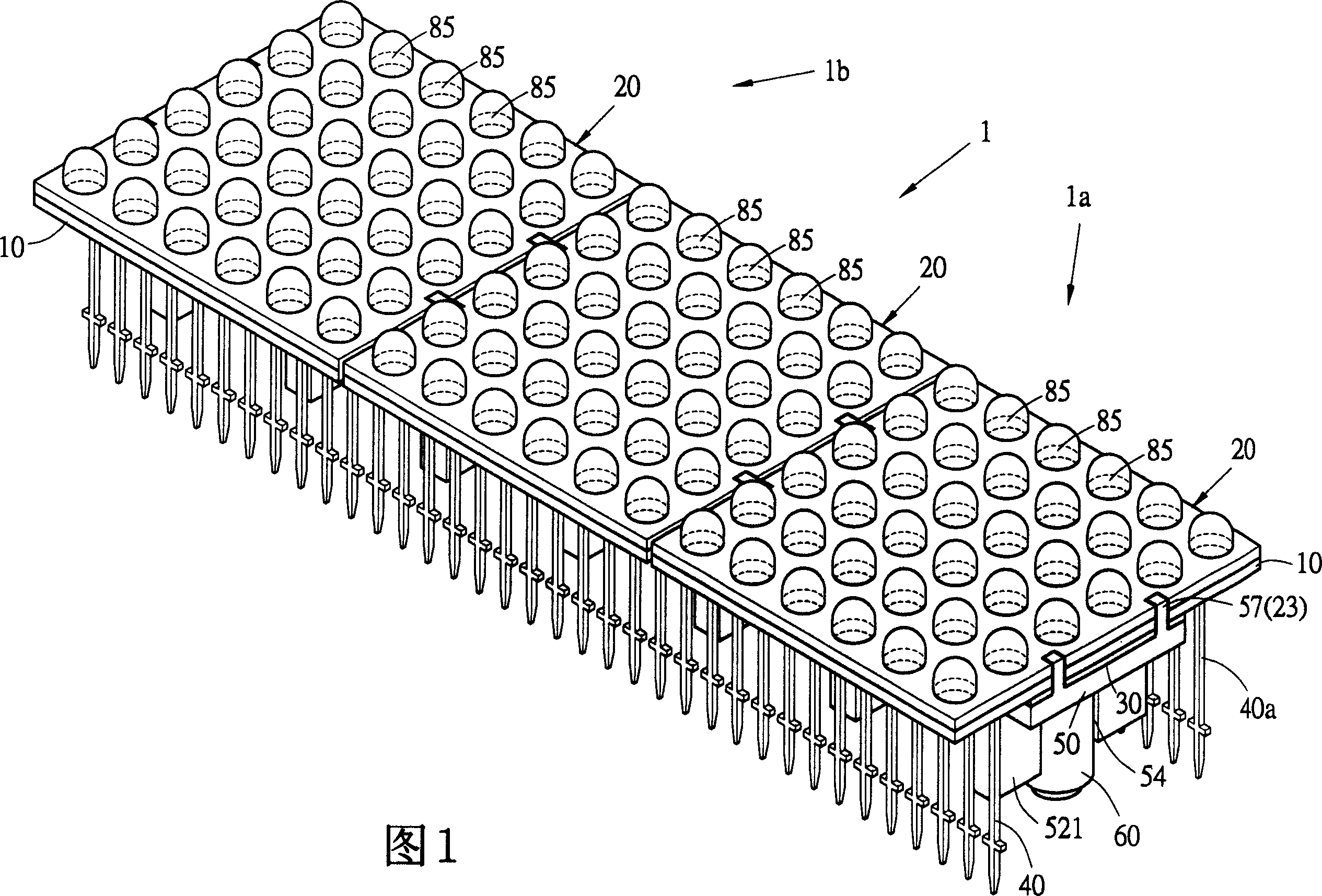

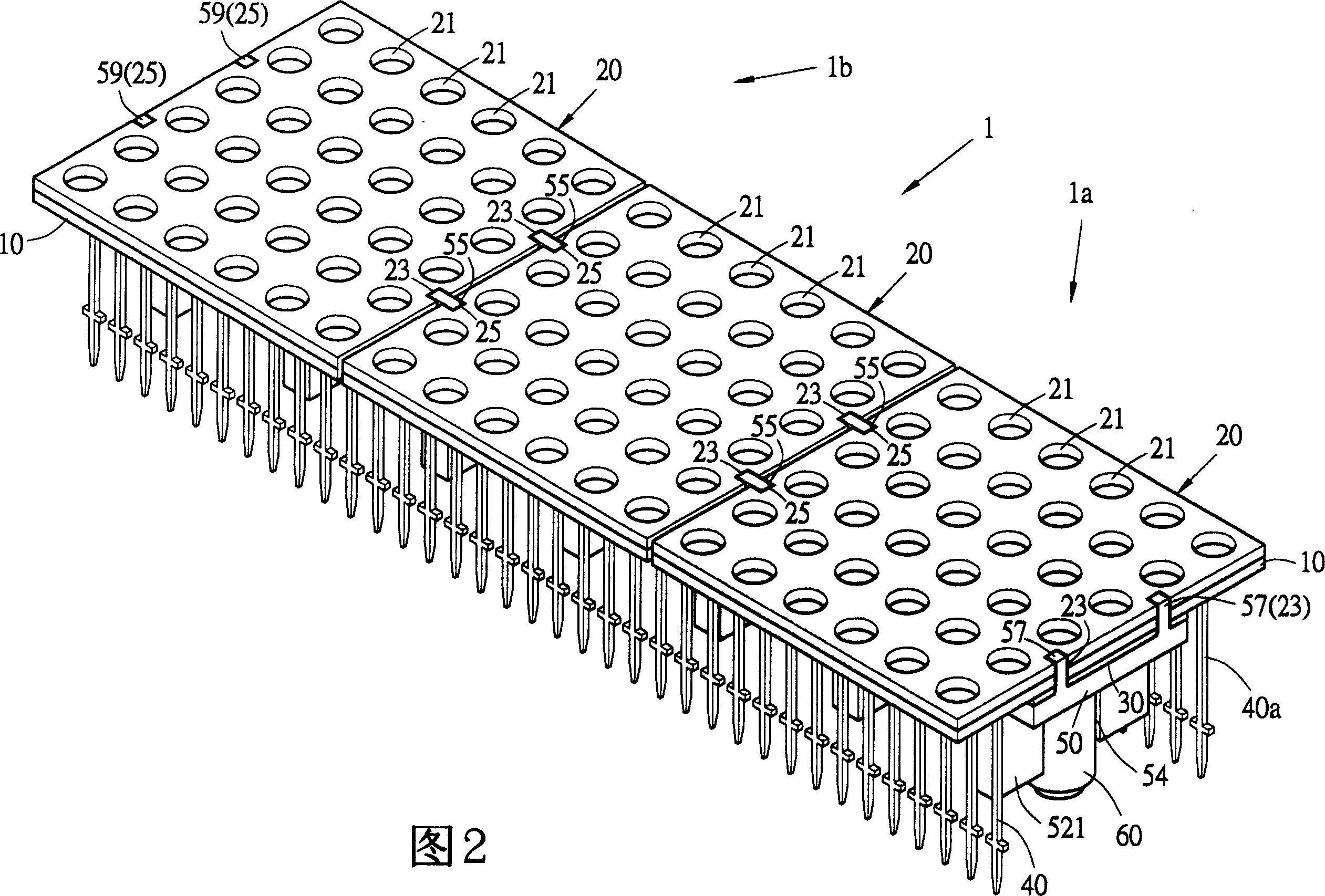

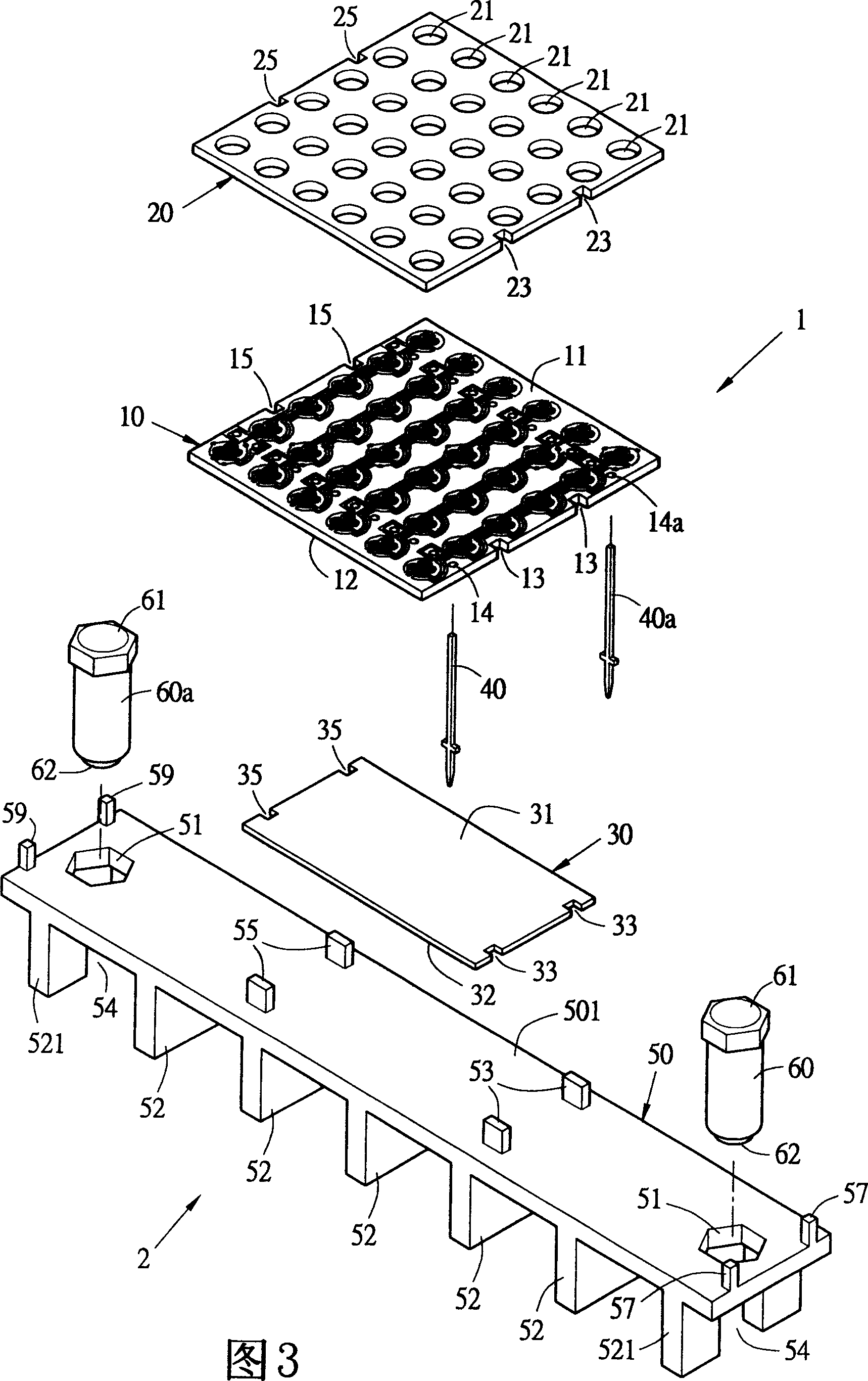

[0039] Please refer to Fig. 1 to Fig. 5, in a preferred embodiment, the device of the present invention can be applied to LED crystal grain groups with three different color grains of R, G, and B as a group, including three groups of substrate units 1 and a group of heat dissipation unit 2, etc., the substrate unit 1 also includes a main substrate 10, a first insulator 20, a second insulator 30, a pair of terminal groups 40, 40a, etc., the heat dissipation unit 2 also includes a heat dissipation body 50, and a pair of fixed columns 60, 60a, etc., wherein:

[0040] The main substrate 10 is a flat insulator with better thermal conductivity, and the LED crystal grain group with R, G, and B crystal grains as a group is arranged in a matrix on the top surface 11, and the top surface 11 has a Each R, G, B crystal grain group corresponds to the positive circuit connected and conducted, and the negative circuit is arranged on the bottom surface 12. A pair of positioning holes 13, 15 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com