Grinding device for shadow mask support

A cover frame and grinding technology, applied in the field of grinding devices, can solve the problems of low work efficiency, low productivity, increased processing time, etc., and achieve the effect of reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

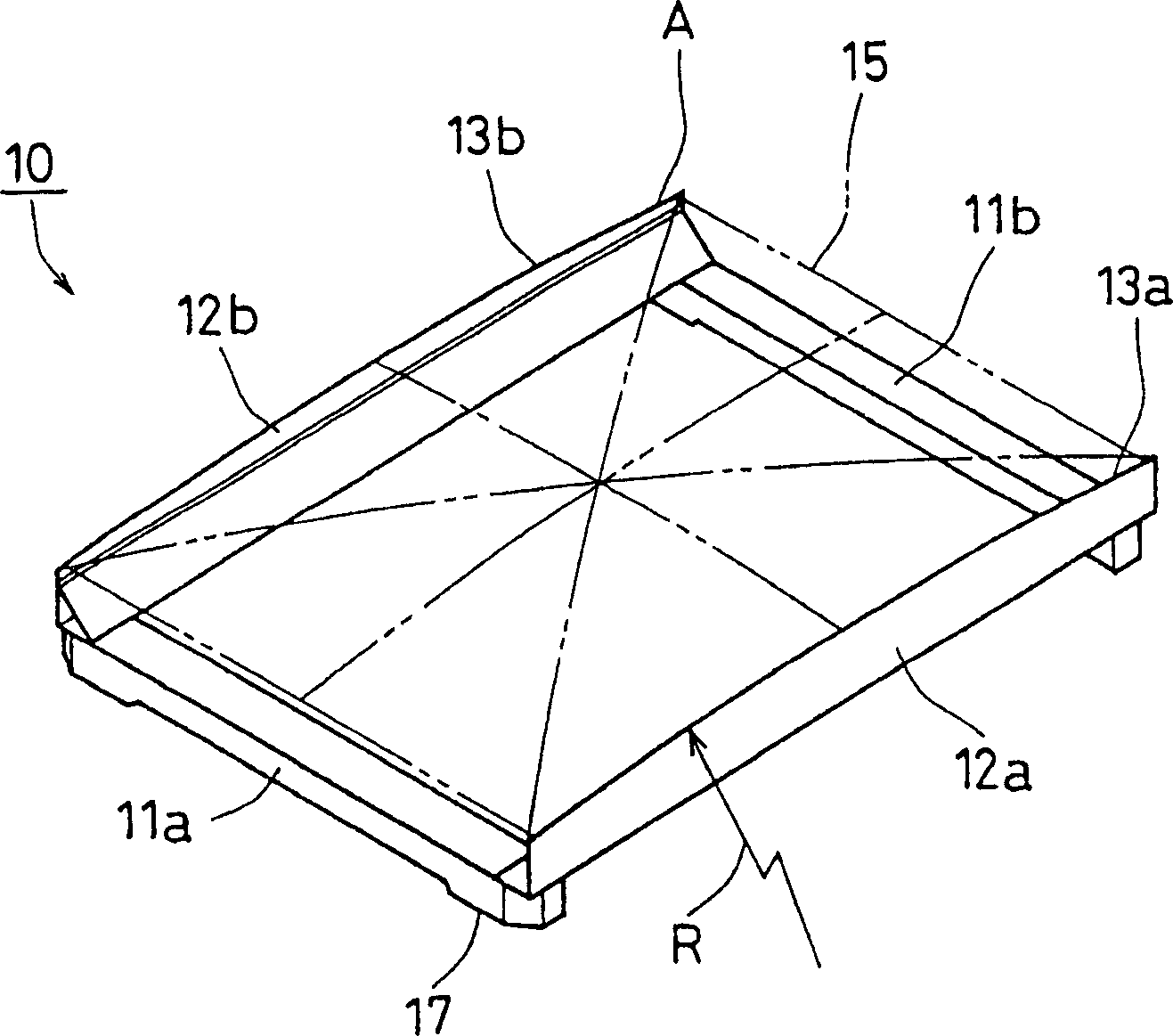

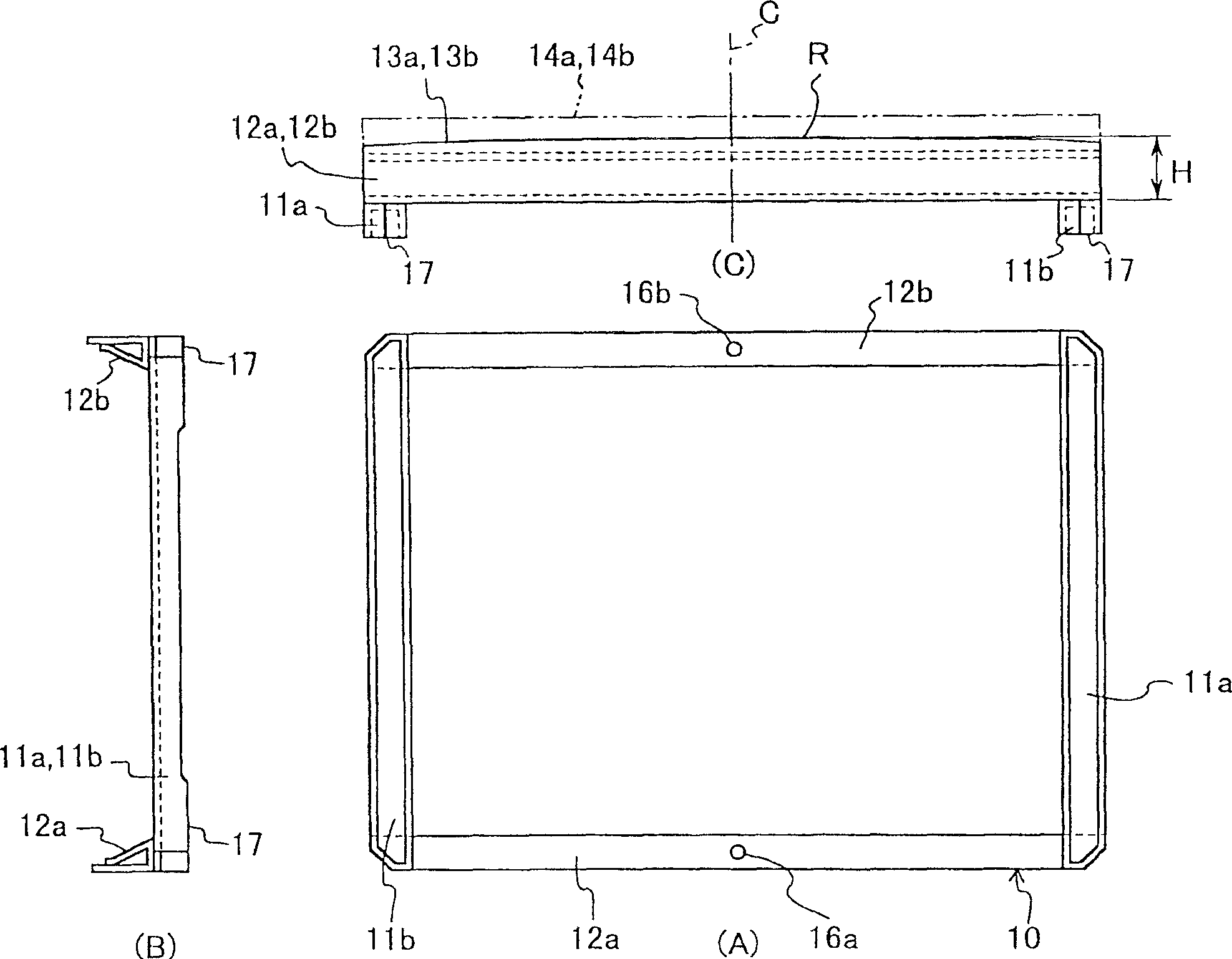

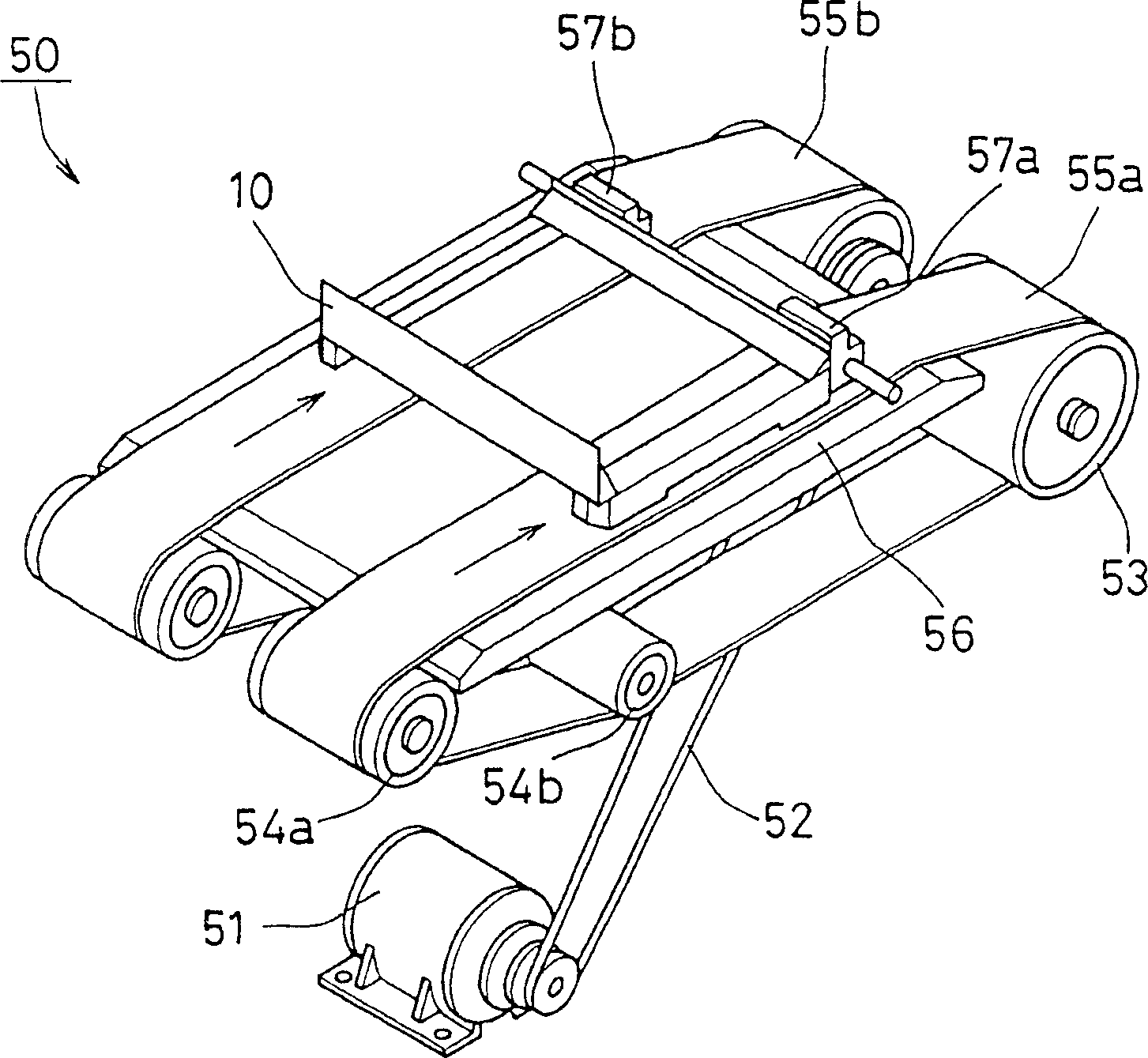

[0025] Below, see Figure 1-Figure 6 Embodiments of the present invention will be described.

[0026] figure 1 is an oblique sketch showing the structure of the mask frame. while in figure 2 The shadow mask frame structure is also shown, figure 2 (A) is a bottom view, figure 2 (B) is the left side view, figure 2 (C) is a front view.

[0027] As shown in the figure, the shadow mask frame (frame, hereinafter referred to as the frame) 10 is composed of a pair of short side frames 11a, 11b arranged in parallel and a pair of long side frames 12a, 12b arranged in parallel, and the short side frames 11a, 11b and The long side frames 12a, 12b are welded together at the ends. The short side frames 11a and 11b are formed by bending a metal flat plate into a substantially U-shaped cross section. On the other hand, the long side frames 12a, 12b are formed by bending a flat metal plate so that the end faces are substantially triangular. The metal plates forming the long side f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com