Thickening-optical glue-symmetrical thinning processing method of high-precision ultra-thin optical parts

An optical part, symmetrical thinning technology, applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve problems such as deformation, achieve low surface roughness, high-precision flatness, and avoid uncontrollable deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

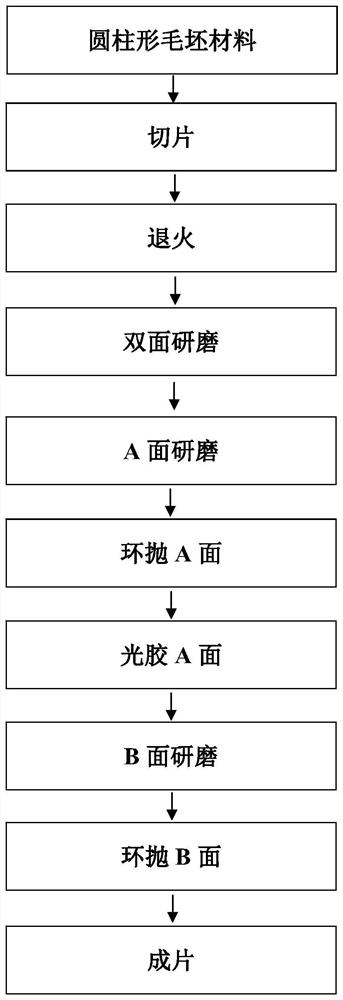

[0023] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 Shown, taking quartz glass as an example, the present invention comprises the following steps:

[0024] In the first step, the quartz blank material is cut into discs with a diameter of 15 mm and a thickness of 0.8 mm.

[0025] In the second step, put the blank material into the annealing furnace for annealing. They are placed side by side on alumina ceramic discs, the sides are wrapped with quartz wool for heat insulation, and the upper surface is covered with alumina ceramic discs. First, keep the temperature at 1100°C for 120min, then cool down to 950°C at 20°C / h, and then close the annealing furnace to allow the parts to cool down to room temperature with the furnace.

[0026] The third step is to put the wafer into the star wheel for double-sided grinding, and the upper and lower end faces are thinned at the same time to ensure that the thinning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com