Water absorbability resin composition

A technology of resin composition and water absorption, applied in the direction of absorbent pads, other chemical processes, bandages, etc., can solve the problems of reduced absorption capacity, difficult absorption performance, and insufficient improvement of solid-state properties of absorbent products, so as to reduce moisture return , the effect of balanced absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

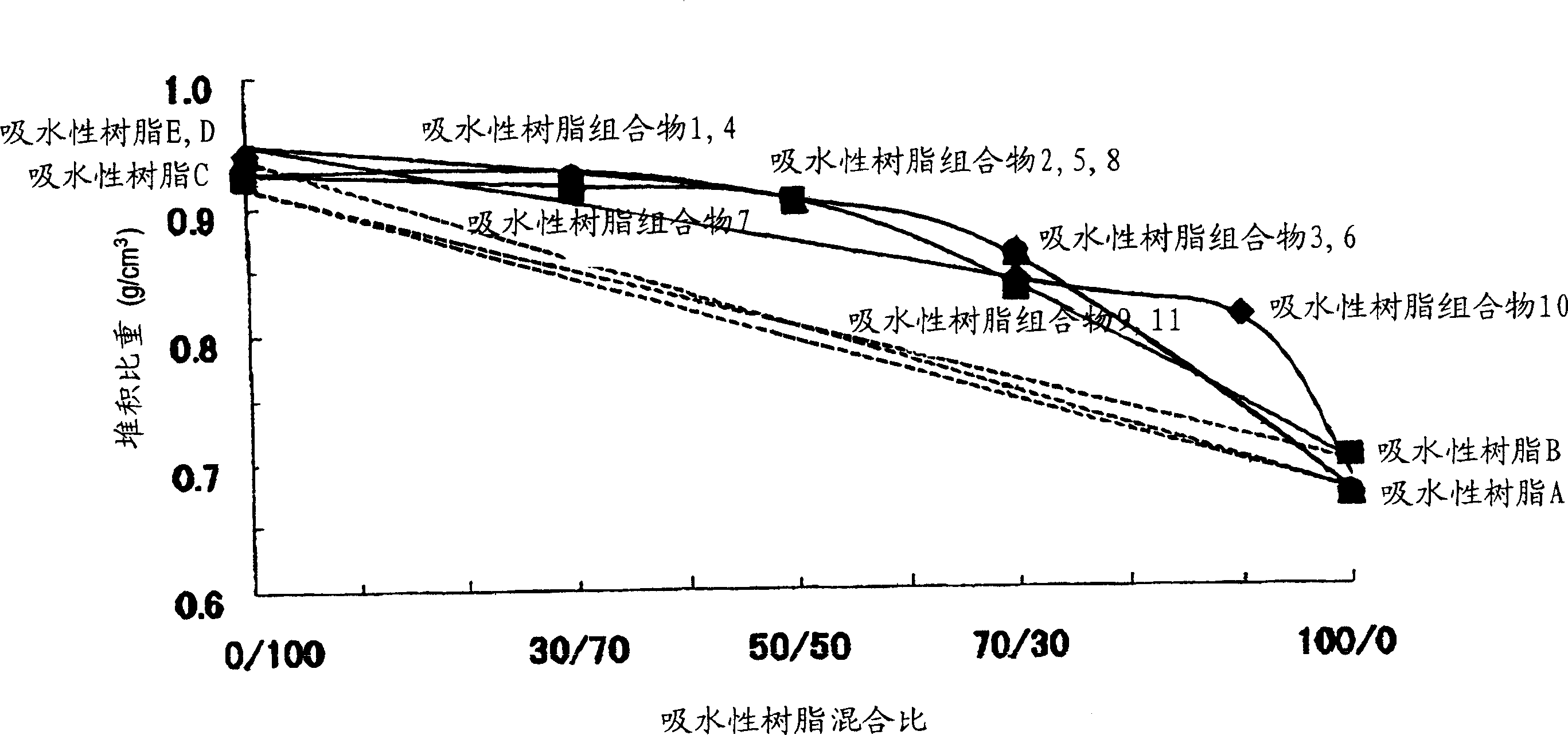

[0184] 30 parts of the water-absorbent resin A obtained in Reference Example 1 and 70 parts of the water-absorbent resin C obtained in Reference Example 3 were charged at a relative humidity of 40% RH into a Redige mixer (manufactured by Redige Corp, sold under the designation "TypeM5R") to Stirring was carried out at 330 rpm for 15 seconds to obtain a water-absorbent resin composition (1).

Embodiment 2

[0186] The water-absorbent resins A-E obtained in Reference Examples 1-7 were mixed according to the method of Example 1 with the composition ratios listed in Table 8 to obtain water-absorbent resin compositions (2)-(11).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com