Sound insulation floor structure

A floor and lining technology, which is applied in the direction of floor fabrics, local raised floors, floor slabs, etc., can solve the problems of deterioration, decreased durability, increased construction cost of double floors, etc., and achieves low cost, good work performance, The effect of good walking sensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Hereinafter, the present invention will be specifically described by illustrating the embodiments and experimental examples shown in the drawings.

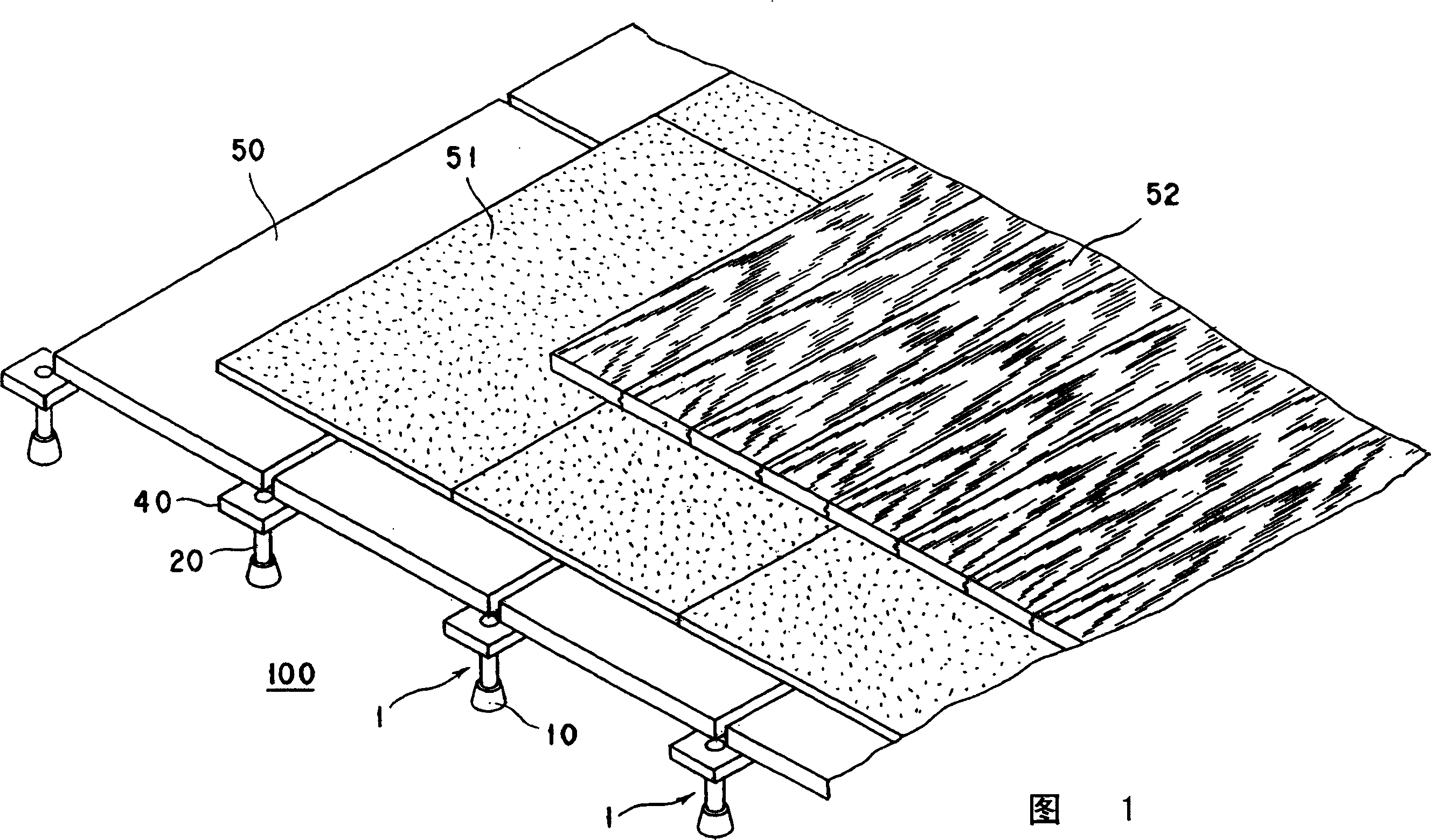

[0038] Fig. 1 shows that at the floor surface of a base ground 100 such as a concrete slab, by means of a unit support foot 1 as a support foot, an underfloor liner 50 is supported and laid at a predetermined height level, and then an An embodiment of a soundproof floor structure formed by laying hard boards or high-density fiberboards 51 to form the lower floor in a double floor, and then laying floor covering materials 52 as floor covering materials.

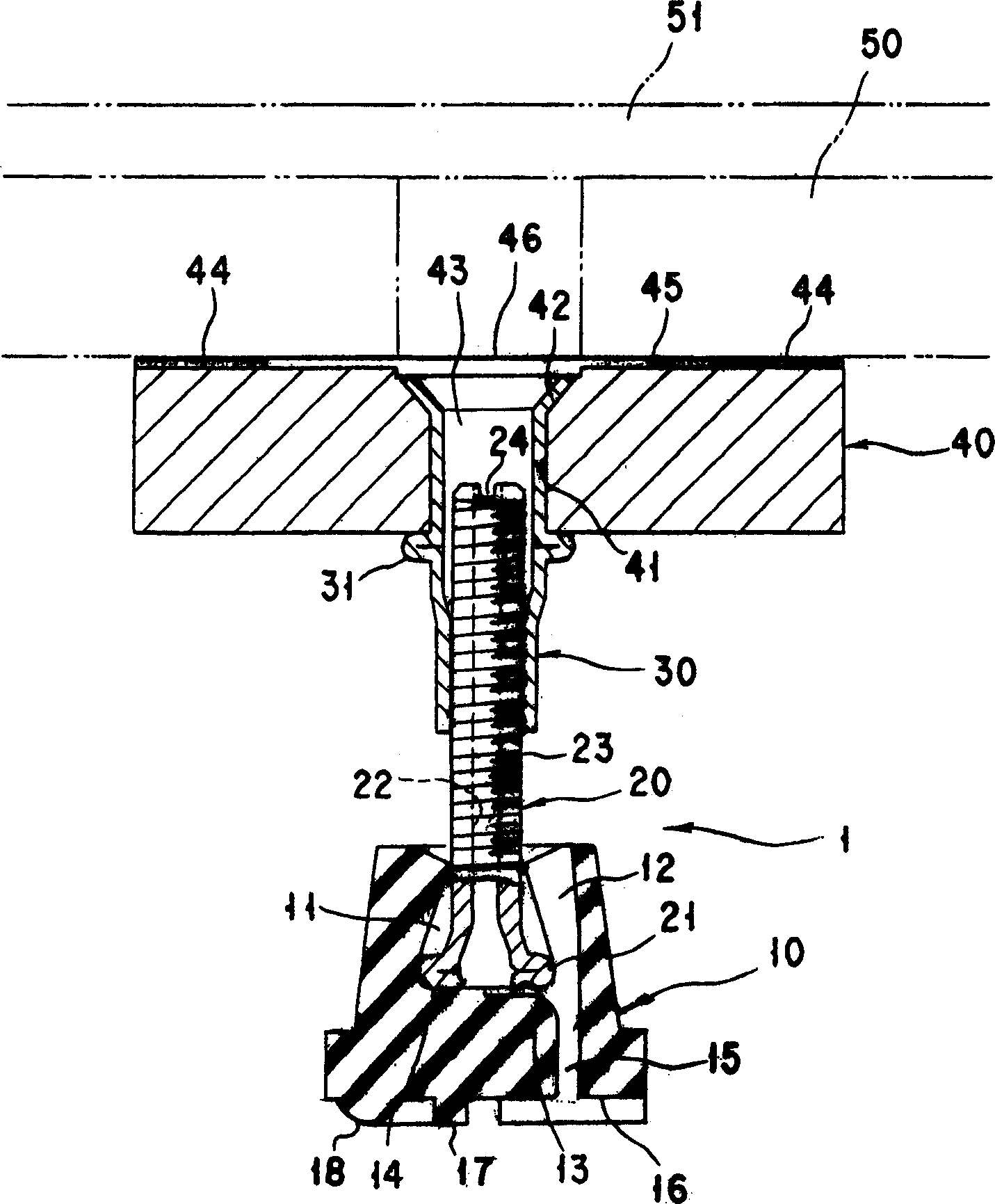

[0039] Figure 2 to Figure 4 A preferred embodiment of unit support feet using hollow type support bolts is shown.

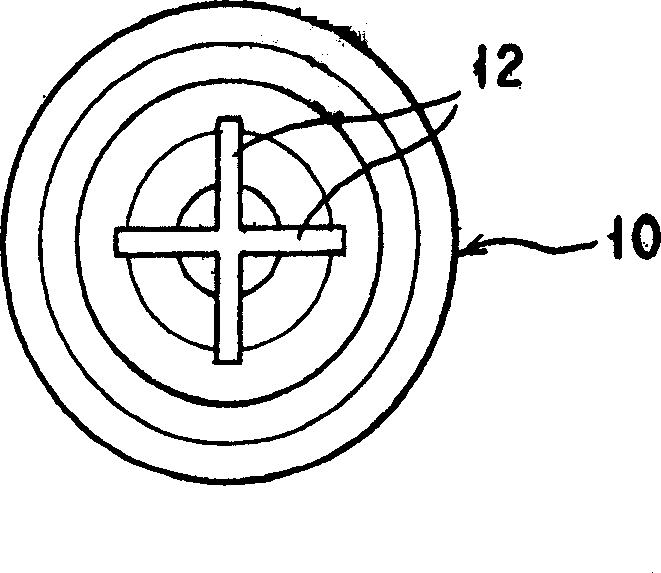

[0040] The unit support foot 1 of this embodiment includes an elastic base 10 formed of elastic materials such as rubber and having shockproof performance, and a foot member composed of a hollow support bolt 20 that is vertically arranged on the elastic base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com