Transmission line having photonic band gap coplanar waveguide structure and method for fabricating power divider using the same

A power divider and coplanar waveguide technology, which is applied in the field of transmission lines, can solve the problems of easy breakage of signal lines, difficulty in manufacturing, and difficulty in high-impedance transmission lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

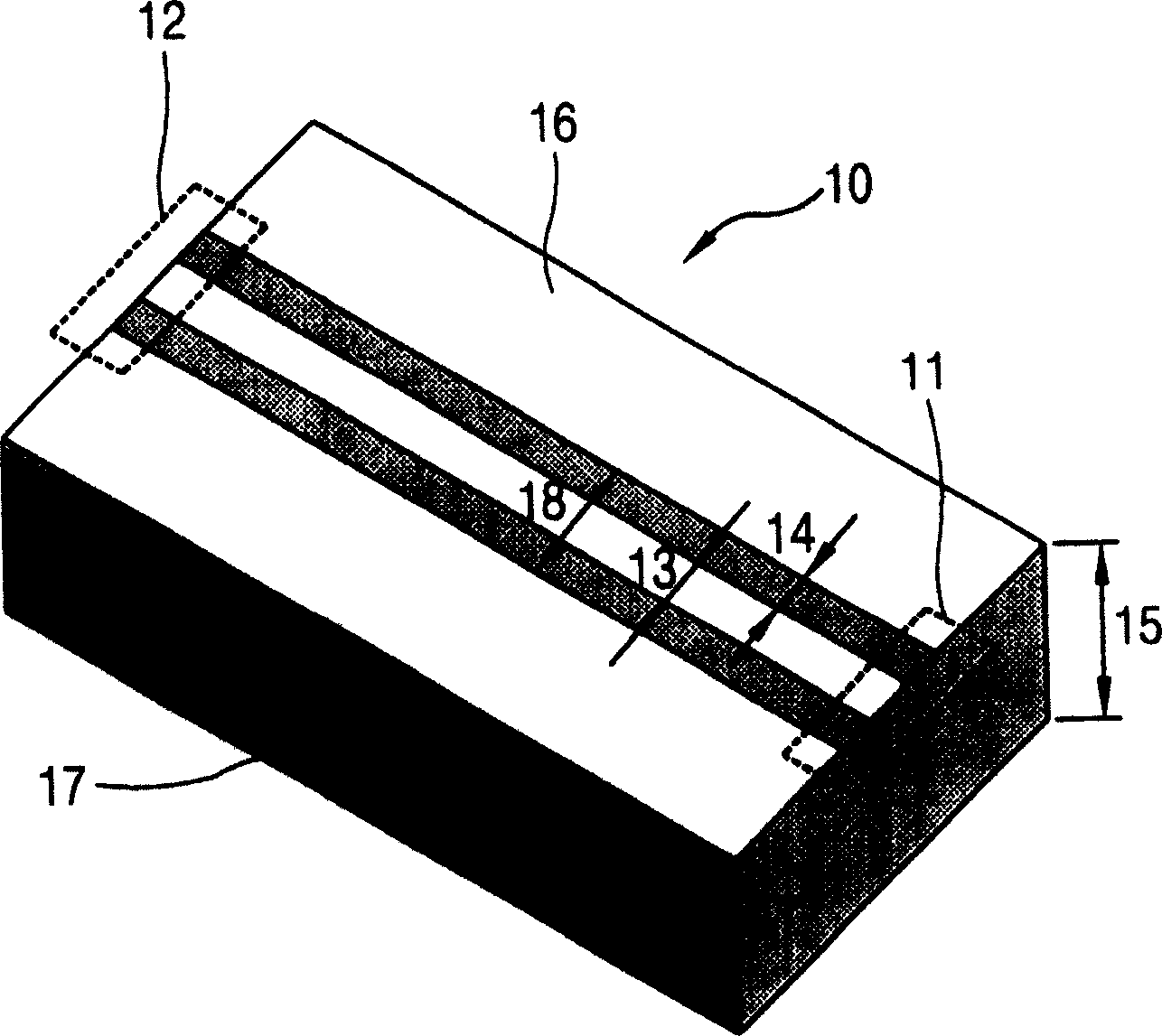

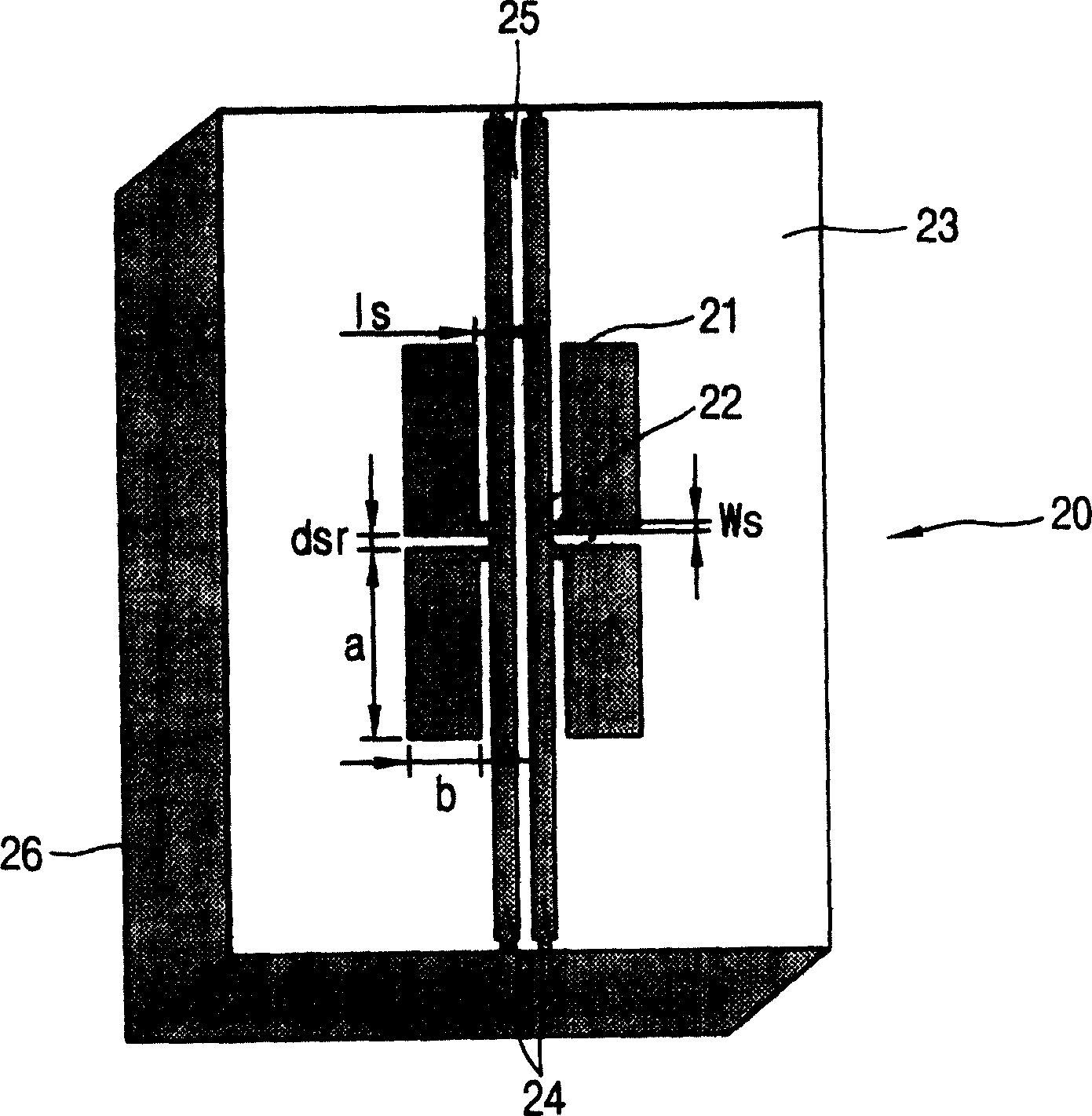

[0033] In the following, reference will be made to Figure 2-11 A preferred embodiment of a transmission line having a photonic bandgap (PBG) coplanar waveguide (CPW) structure and a method of using the transmission line to fabricate a power divider that increases the characteristic impedance, increases the signal line width of the transmission line, and provides high power is described.

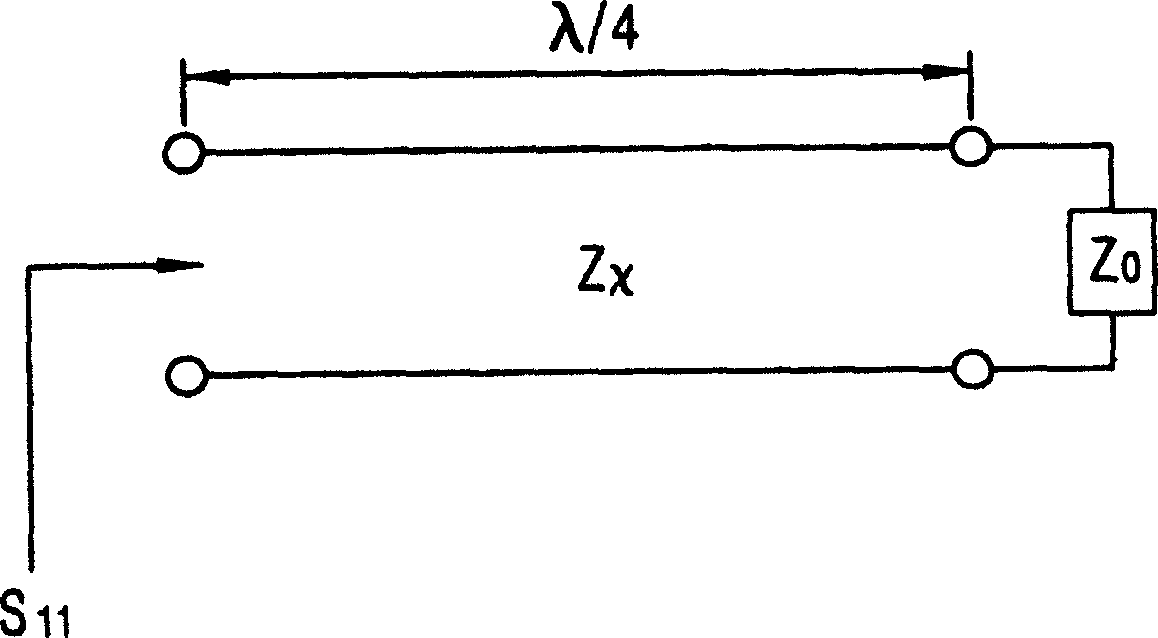

[0034] figure 2 is a diagram for describing the present invention showing a normal transmission line with its load side short-circuited.

[0035] As shown in the figure, when the load terminal (load impedance Z o ) is short-circuited, the characteristic impedance of the transmission line becomes Z X . Here, the input end of the transmission line S 11 is the reflection coefficient.

[0036] When the length of the transmission line is λ / 4, the characteristic impedance of the transmission line (Z X ) coincides with the maximum reflection coefficient value and can be obtained from the sig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap