Process for preparing cylindrical press ring form primary and secondary Zn-Ni battery

A cylindrical and pressure ring technology, applied in two new energy fields, can solve the problems of alkaline zinc-manganese batteries with poor heavy-load performance, poor high-current work performance, and no granulation process, etc., to improve shelf life and conduct electricity Good performance, the effect of reducing the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

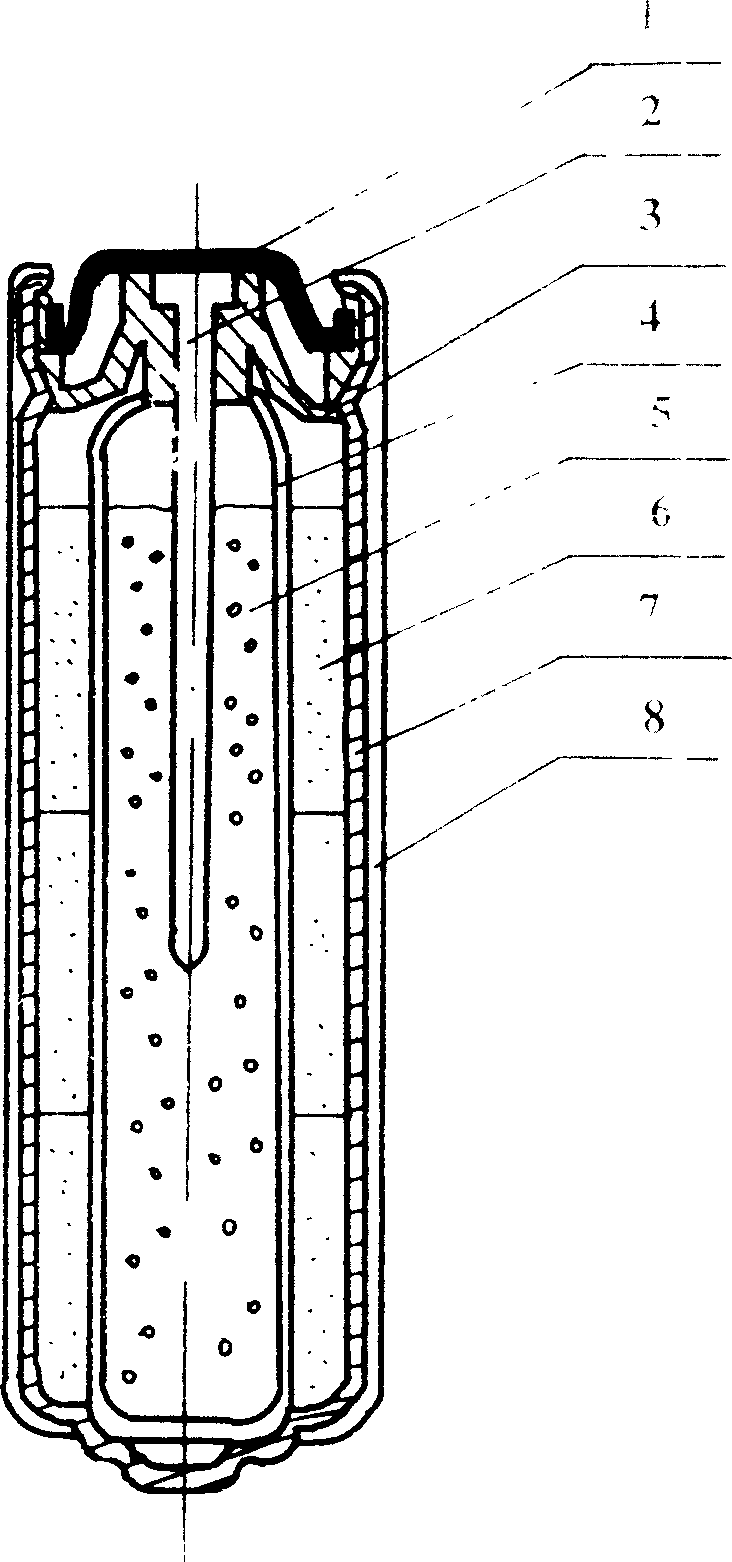

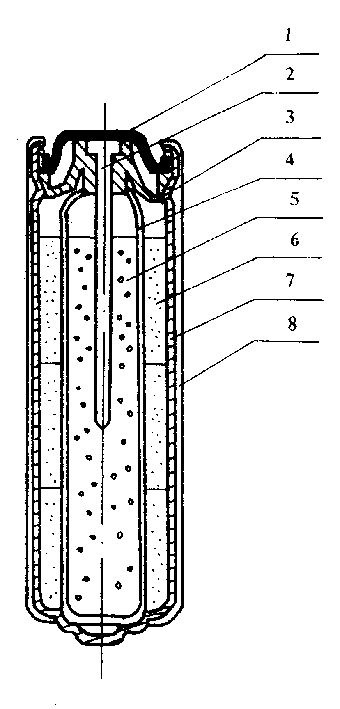

Image

Examples

Embodiment 1

[0022] Example 1 Preparation of AA size primary Zn-Ni battery

[0023] Weigh 90g of self-made NiOOH powder, 10g of graphite powder, 1g of additive, 0.5g of binder, dry mix for 20 minutes, add 10g of KOH solution with a weight ratio of 38%, and wet mix for 30 minutes. Thickness: 0.2-0.5mm, crushed and pressed into tablets, then crushed and then sieved, the upper sieve is 40 mesh, and the lower sieve is 80 mesh. Store the powder that has passed the upper sieve and the powder that has not passed the lower sieve. The powder that does not pass the upper sieve is crushed and sieved. The powder that passes through the lower sieve is then compressed into tablets to repeat the above process. Measure the particle size distribution and apparent specific gravity of the qualified powder. The apparent specific gravity is 1.68g / cm 3 , The particle size is between 40-200 mesh, 40-60 mesh accounts for 5%, 60-80 mesh accounts for 80%, 80-100 mesh accounts for 10%, and 100-200 mesh accounts ...

Embodiment 2

[0028] Example 2 Preparation of AA-sized secondary Zn-Ni battery

[0029] With β-Ni(OH) 2 90g, graphite powder 10g, additive I 2g, additive II 1g, binding agent 0.5g, dry mix 20 minutes, add weight ratio 38% KOH solution 10g wet mix 30 minutes, other is the same with example 1. The weight of the ring pressed by 2.8g of granulated qualified powder is 2.7g, and the ring height is 12mm. Three rings are put into the steel cylinder and repressed. ) into a negative electrode collector to make a battery, charged with a small current of 100mA, and discharged to 1.0V with a constant current of 200mA. After charging and discharging 3 times, the capacity is about 800mAh.

[0030] The ring strength of ungranulated powder is not good, water will be generated after charging, and the ring will be loose and deformed.

[0031] The present invention is not limited to AA size batteries, and is suitable for cylindrical pressure ring type Zn-Ni primary and secondary batteries of all other spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com