Composite membrane and manufacturing method of the same, color filter and display device equipped therewith

A composite film and film technology, which is applied to the surface coating liquid device, inking device, optical filter, etc., can solve the problem of uneven color density and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

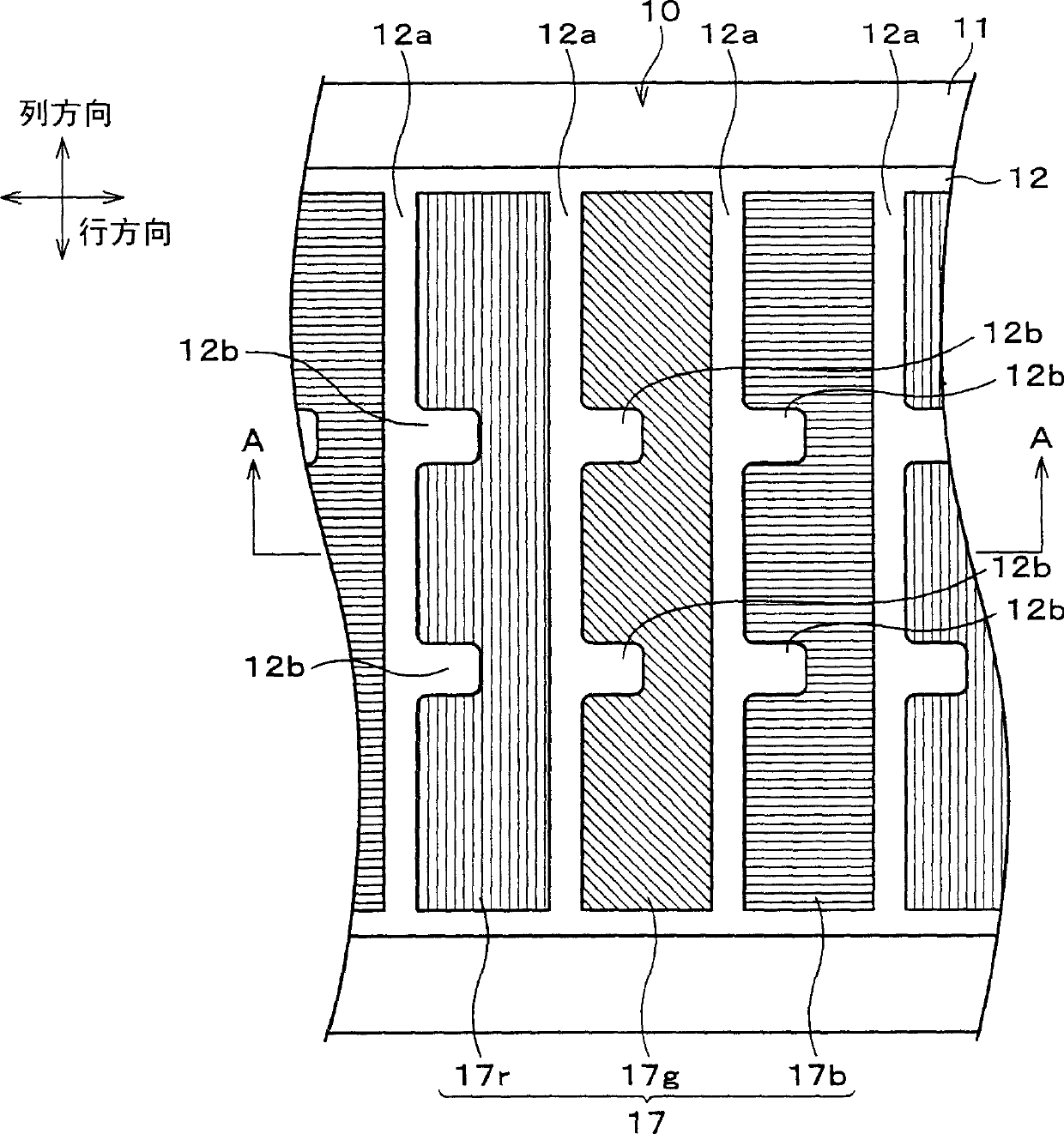

[0078] A first embodiment of the present invention will be described below with reference to FIGS. 1 to 10 .

[0079] 1(a) is a plan view of the color filter 10 of this embodiment, and FIG. 1(b) is a cross-sectional view taken along line A-A of FIG. 1(a).

[0080] The color filter 10 is disposed on a substrate 11 . The color filter 10 is provided with color segments 17 as a transparent color film, and a black matrix 12 as a light shielding film. The color segment 17 includes a red segment 17r, a green segment 17g, and a blue segment 17b, corresponding to three primary colors RGB.

[0081] Here, the color segment 17 is a thin film formed by curing a thin film material applied by an inkjet method described below. In the color segments 17 thus formed, red segments 17r, green segments 17g, and blue segments 17b are patterned in a stripe shape.

[0082] The black matrix 12 acts as a spacer that separates adjacent color segments in the applied film material, i.e., is used to sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com