Opto-electronic device integration

A device and electronic chip technology, applied in the field of optoelectronic device integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

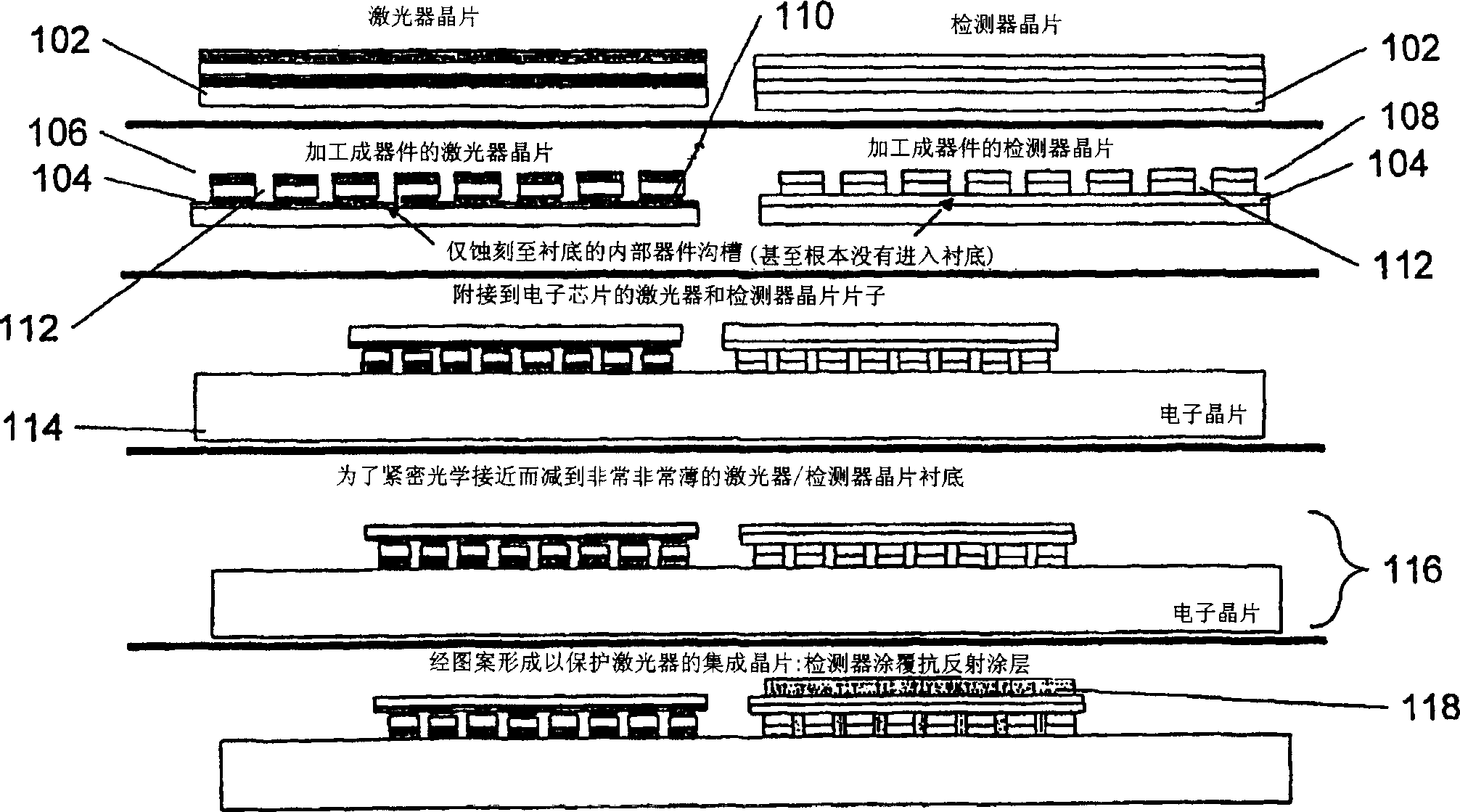

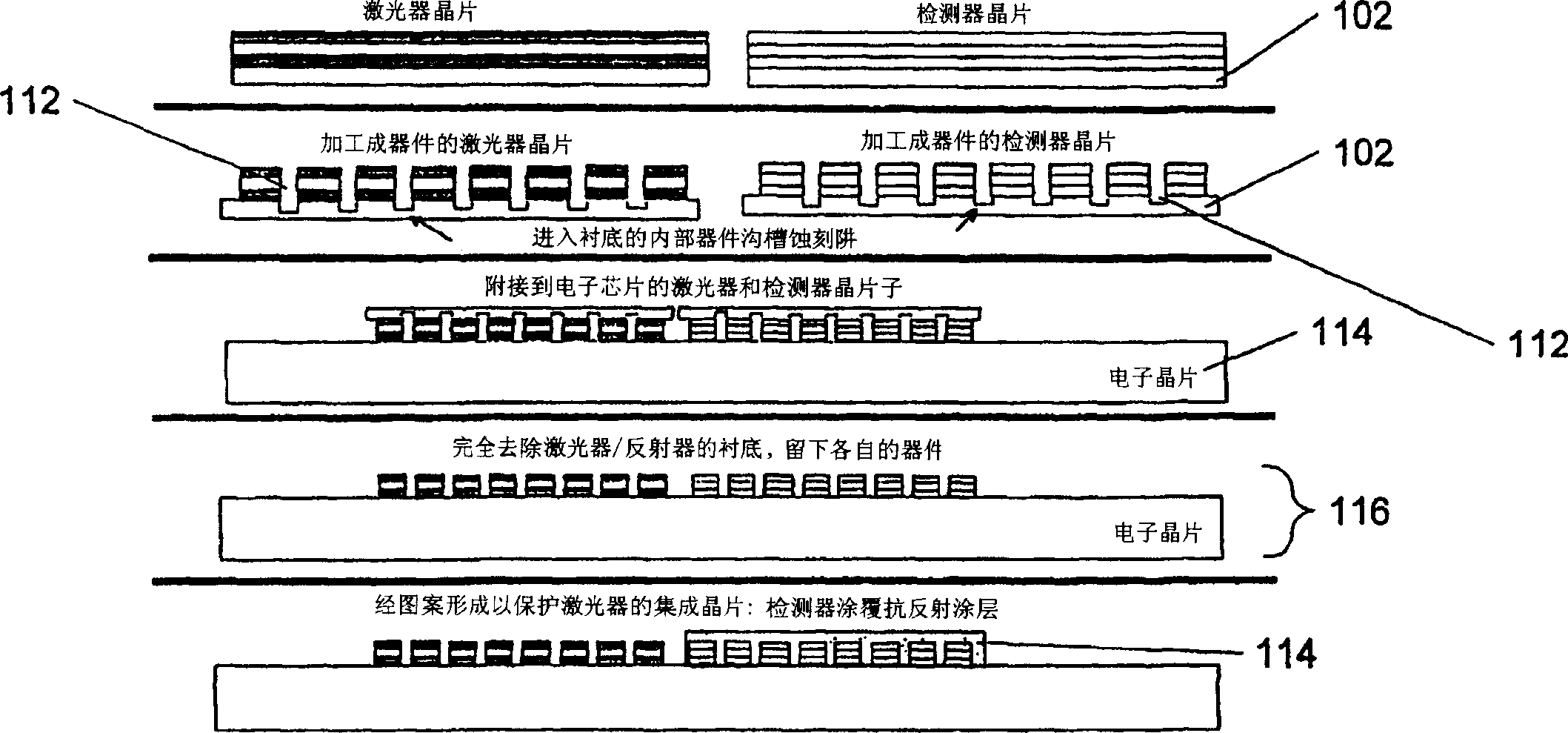

[0063] Figure 5 An exemplary method in accordance with the techniques of the present invention is illustrated at a simplified high-level overview. This process allows close optical proximity, eliminates absorbing regions, provides higher structural integrity, and has better heat dissipation characteristics while overcoming the disadvantages of the prior art.

[0064] exist Figure 5 In this method, laser wafer 502 (consisting of lasers integrated with substrate 102) or detector wafer 504 (consisting of detectors integrated with substrate 102) is obtained using conventional techniques or purchased from some third party. device configuration). Alternatively, hybrid chips consisting of lasers and detectors integrated on a common substrate in some pattern or grouping can also be manufactured or purchased.

[0065] The etched trenches 506 process a wafer into individual discrete devices (by etching into the substrate) or in some cases into groups of suitable devices, e.g. What...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com