Roll curve of continuous caster with continuous bending section and two continuous straightening sections

A technology of straightening section and bending section, which is applied in the field of straight-arc and arc-shaped continuous casting machine roll curves, and can solve the problem of bending and straightening sections that cannot be used for straight-arc continuous casting machines, and arc-shaped continuous casting machines that cannot be used Problems such as straightening section and slab internal cracking can be achieved to reduce construction investment, reduce height and prevent internal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

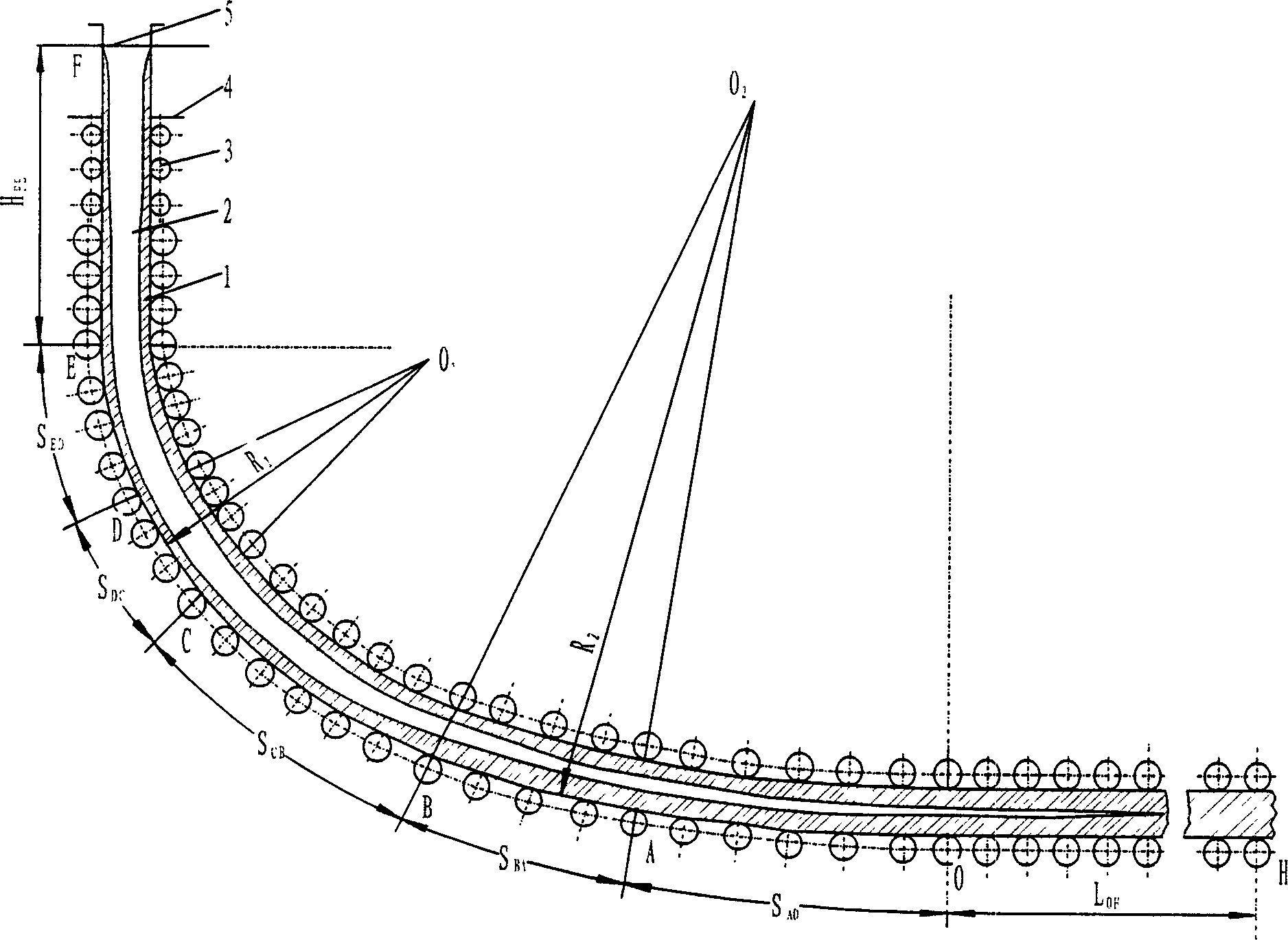

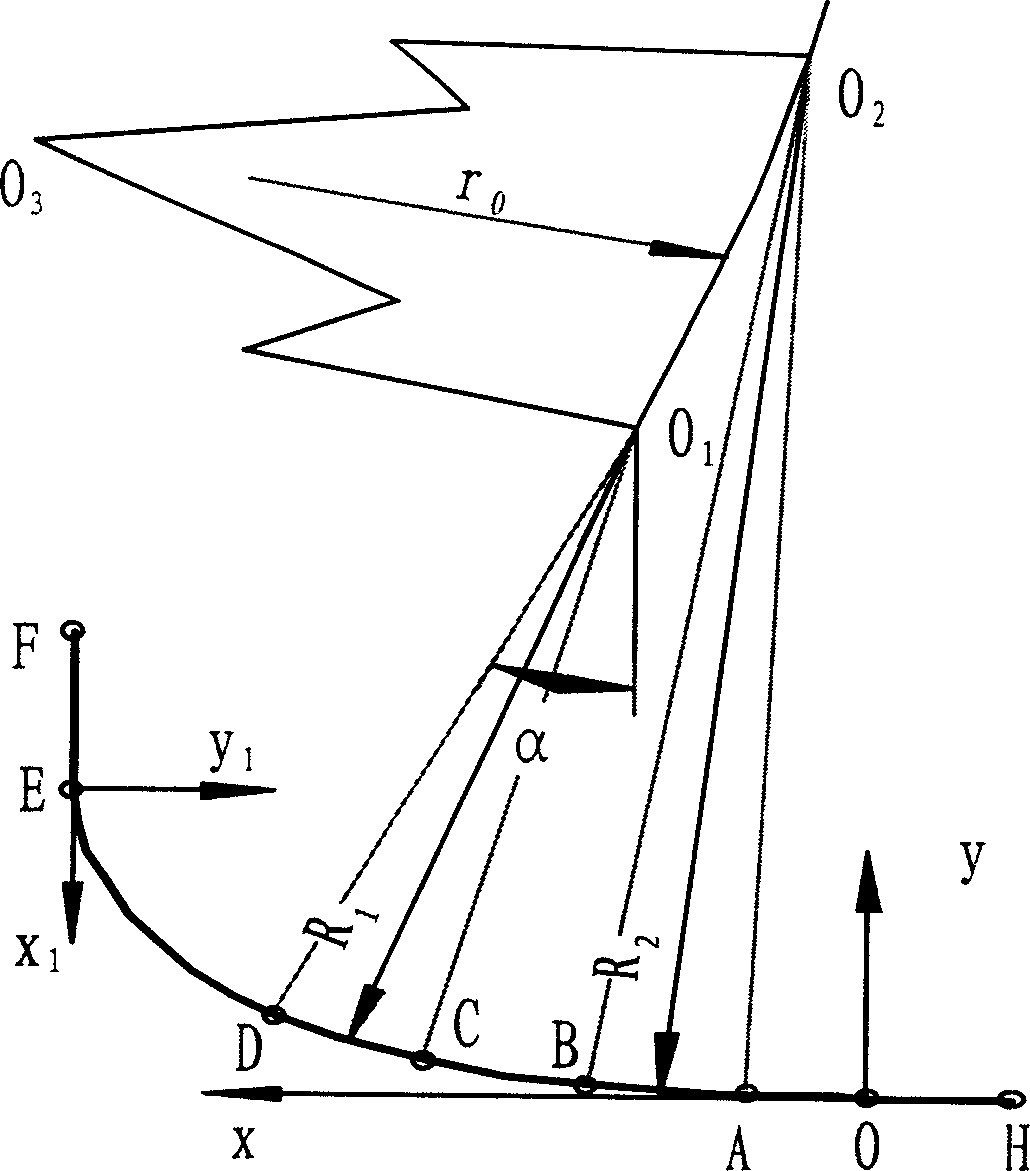

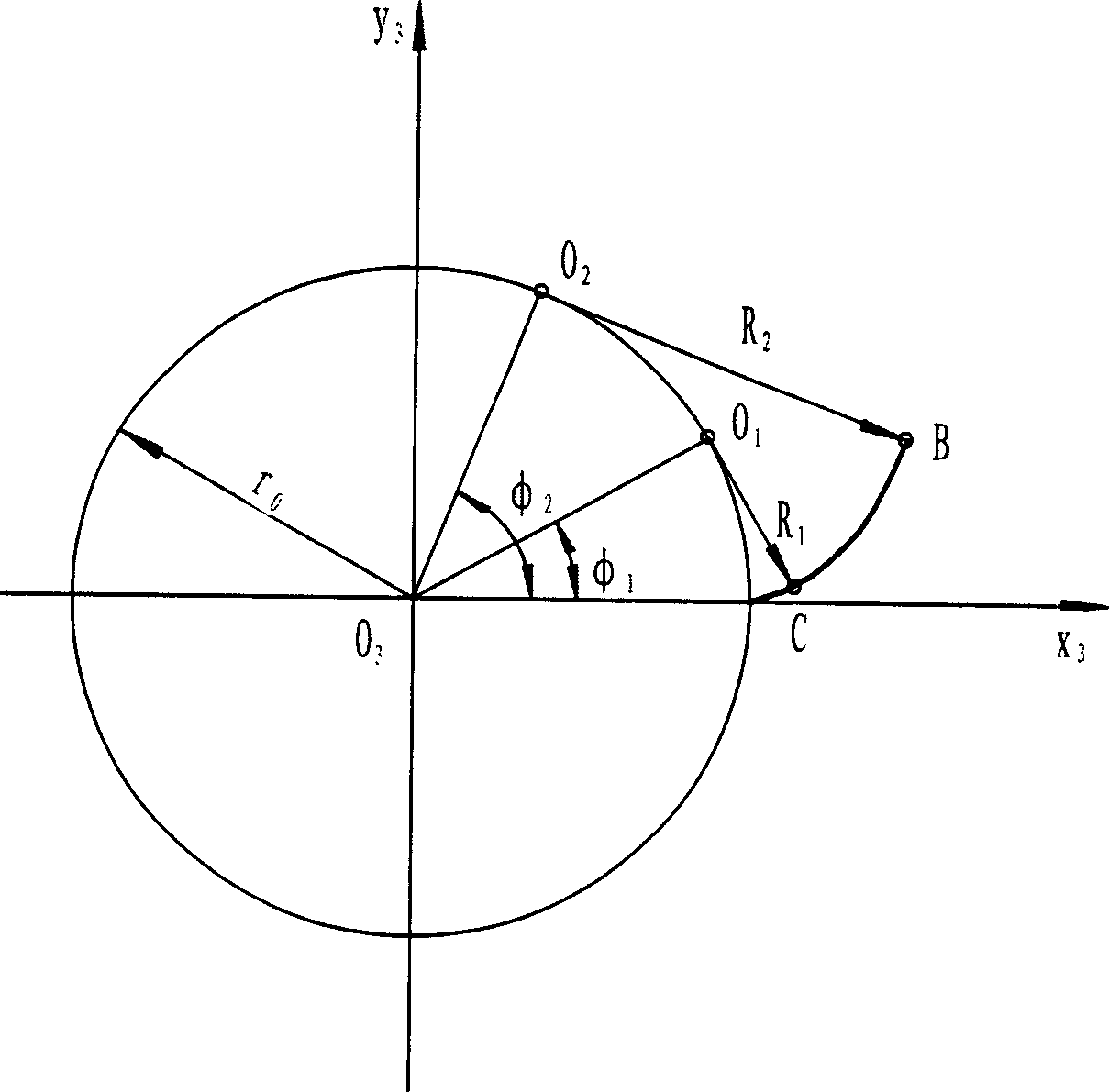

[0053] Continuous caster roll row curve with a continuous bending section and two continuous straightening sections, the curve consists of a vertical section H FE , continuous bending section S ED , basic arc segment S DC , the first continuous straightening section S CB , transition arc segment S BA , the second continuous straightening section S AO and horizontal section L OH composition (see figure 2 ).

[0054] The maximum thickness of the slab D = 250mm, the maximum working speed V C = 1.7 m / min , Metallurgical length L of the slab e =37825mm, arc length S of the second continuous straightening zone OA =2170mm, the arc length S of the transition arc segment AB =5160mm, transition arc radius R 2 =10300mm, arc length S of the first continuous straightening zone BC =1000mm, arc length S of basic arc segment CD =5875mm, basic arc radius R 1 =7500mm, arc le...

Embodiment 2

[0059] The roll row curve of a straight-arc continuous caster with a continuous straightening section, the curve consists of a vertical section H FE , continuous bending section S EB , basic arc segment S BA , continuous straightening section S AO and horizontal section L OH composition.

[0060] The maximum thickness of the slab D = 250mm, the maximum working speed V C = 1.7 m / min , Metallurgical length L of the slab e =37825mm, continuous straightening section curve arc length S OA =2170mm, arc length S of basic arc segment AB =14500mm, basic arc radius R 2 =10300mm, arc length S of continuous bending section curve BE To be requested, the vertical segment length H FE =2000mm, horizontal section length L OH to be requested.

[0061] The coordinate values of the design and calculation results of the roll row curve of the continuous casting machine in the Car...

Embodiment 3

[0065] Roller row curve of an arc-shaped continuous casting machine with two continuous straightening sections, the curve is composed of a basic arc segment S FC , the first continuous straightening section S CB , crossing arc segment S BA , the second continuous straightening section S AO and horizontal section L OH composition (see Figure 5 ).

[0066] The maximum thickness of the slab D = 250mm, the maximum working speed V C = 1.7 m / min , Metallurgical length L of the slab e =37825mm, arc length S of the second continuous straightening zone OA =2170mm, the arc length S of the transition arc segment AB =4500mm, transition arc radius R 2 =10300mm, arc length S of the first continuous straightening zone BC =1500mm, arc length S of basic arc segment CF To be sought, basic arc radius R 1 =5150mm, horizontal section length L OH To be required, the crystallizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com