Self lubricating wear resistant slide board and its producing method

A self-lubricating, sliding plate technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of reduced smoothness, easy corrosion of steel materials, increased wear, etc., and achieve good effect of lubrication and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

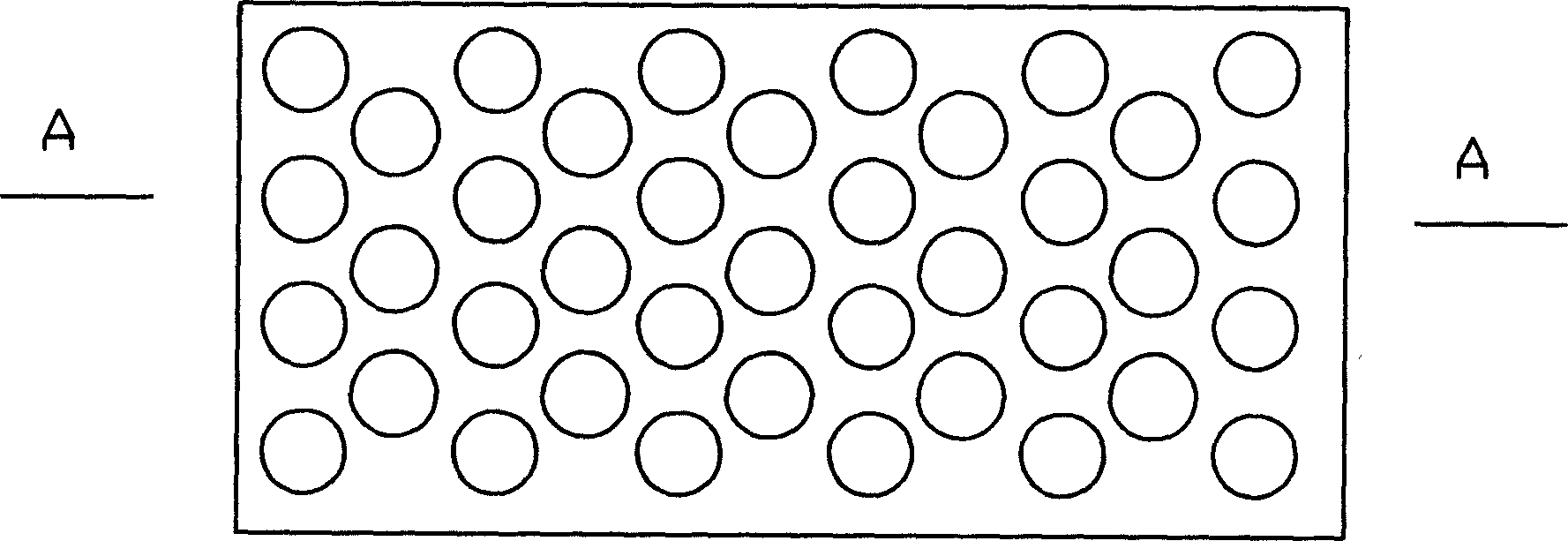

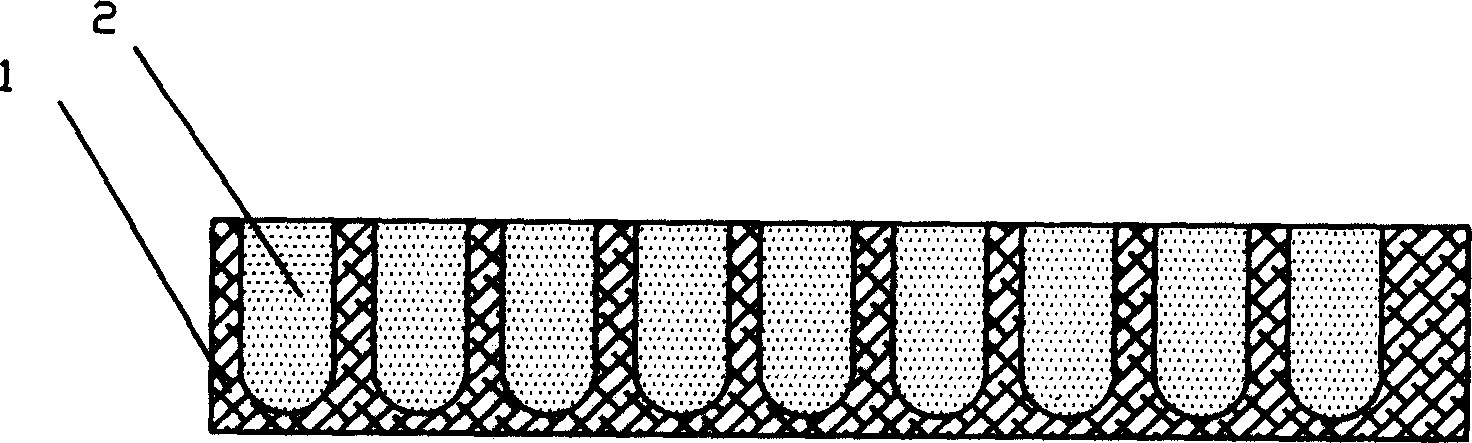

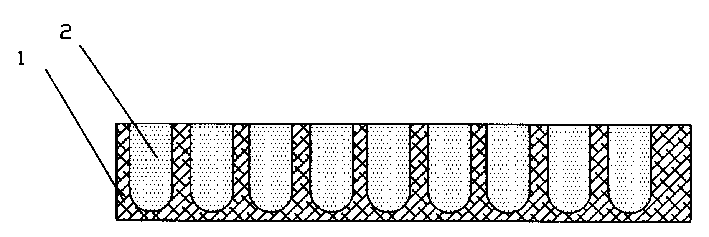

[0010] Such as figure 1 , 2 As shown, the corrosion-resistant, impact-resistant, and insulating Bakelite 1 is used as a substrate, and a number of impermeable holes are drilled on its upper part, and self-lubricating mixed materials 2 are filled in the holes. The self-lubricating mixed material is composed of high-purity graphite powder and industrial paraffin.

[0011] The mixing ratio is: 65% for high-purity graphite powder and 35% for industrial paraffin. Pour the graphite powder into the mixing chamber preheated below 100°C, the purpose is to remove the water in the graphite powder, then put the paraffin wax into the mixing chamber, and stir fully during the addition. After mixing it evenly, fill it into the holes of the Bakelite board preheated to 60°C and compact it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com