Bio-based lubricant base oil

A lubricating oil base oil, bio-based technology, applied in the field of lubricating oil, can solve the problems of poor lubrication and wear resistance, poor oxidation resistance, oxidation resistance, poor lubrication and wear resistance, etc., to achieve easy operation and improve high temperature resistance The effect of performance and large market application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

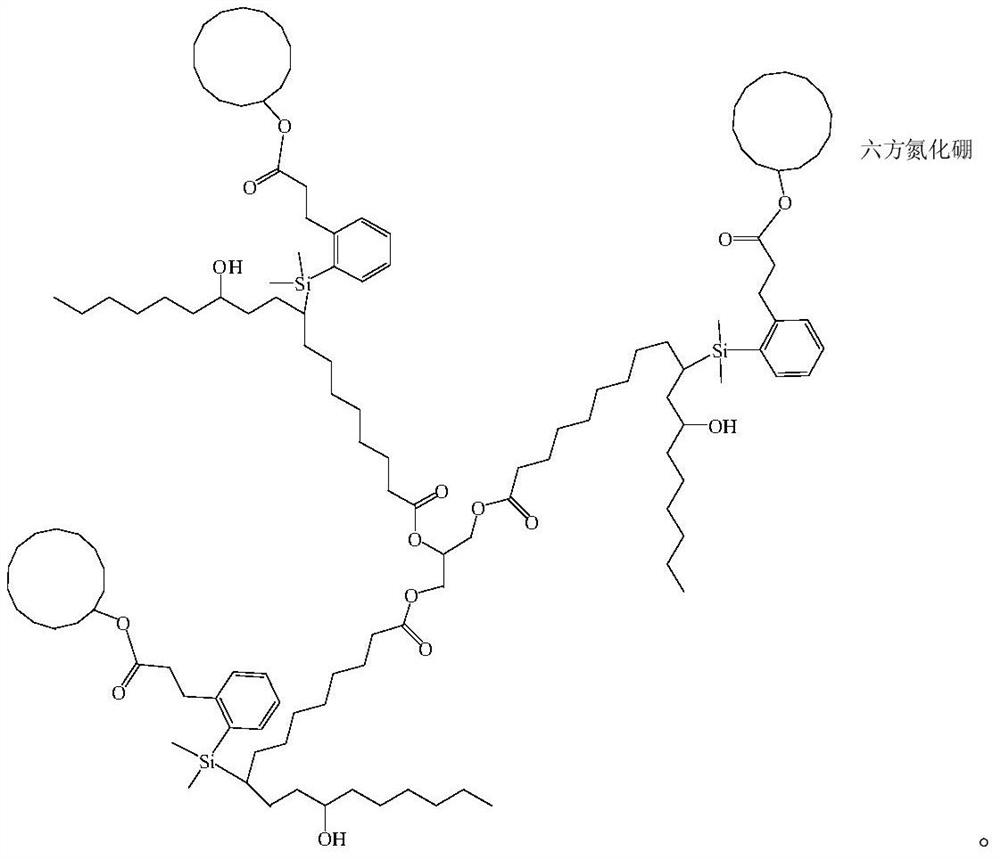

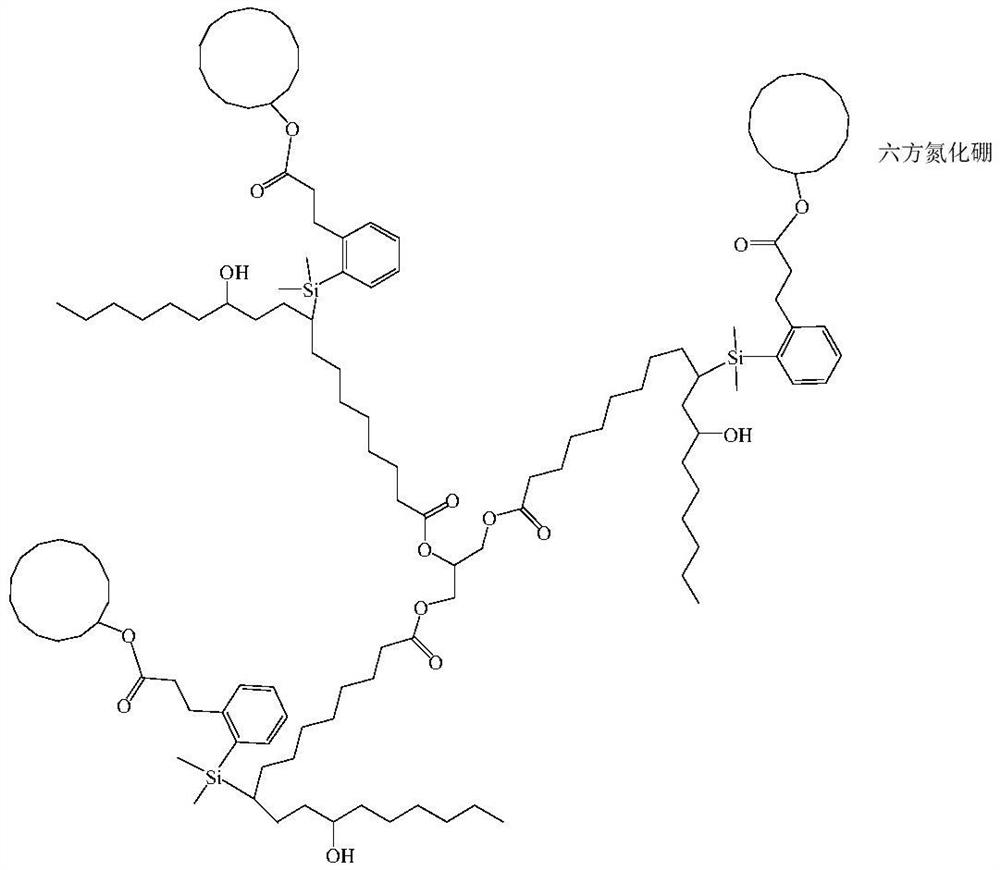

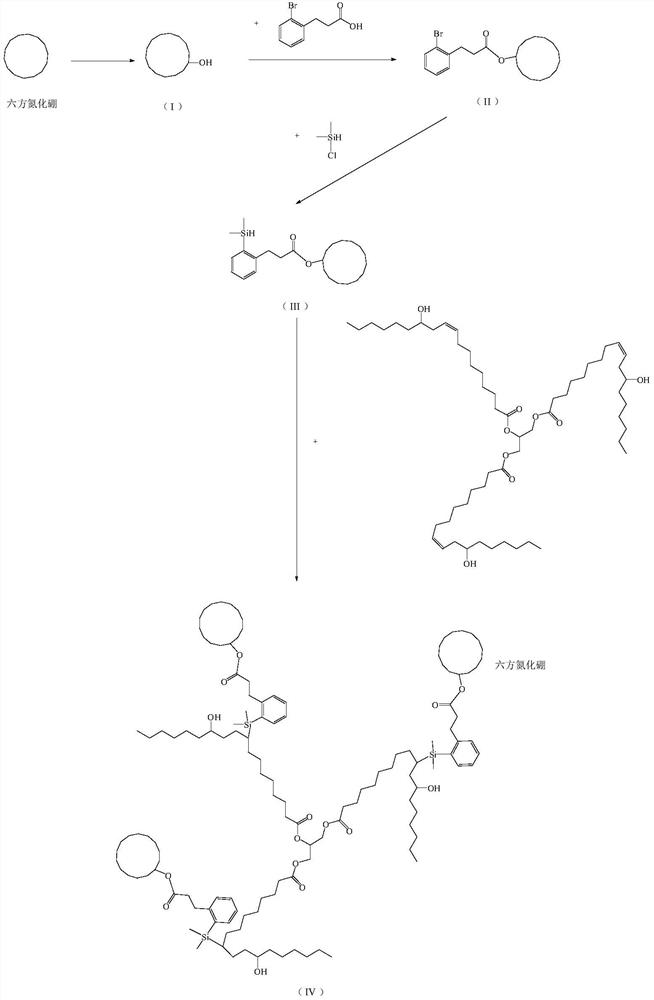

[0035] A preparation method of bio-based lubricating oil base oil, comprising the following steps:

[0036] (1) Disperse 5g of hexagonal boron nitride in 1L of 5mol / L sodium hydroxide solution, put in an ultrasonic wave with an ultrasonic power of 1500W, and react in a reactor at 200°C for 6h to prepare an aqueous solution of hydroxylated hexagonal boron nitride; The hydroxylated hexagonal boron nitride aqueous solution was dialyzed in deionized water for 2 days, then frozen with liquid nitrogen, and dried in a freeze dryer for 2 days to obtain the dried hydroxylated hexagonal boron nitride product I;

[0037] (2) disperse 1, 1.2mol 3-(2-bromophenyl) propionic acid containing 1mol hydroxyl in 20mol DMSO, add 2wt% methanesulfonic acid, stir and heat up to 120 ℃ to react, calculate the quality of dividing water as The end of the reaction; then lower the temperature, filter, wash and dry to obtain the intermediate product II (IR: 3500cm -1 : -OH disappears; 1735cm -1 : -C=O exi...

Embodiment 2

[0042] A preparation method of bio-based lubricating oil base oil, comprising the following steps:

[0043] (1) Disperse 1 g of hexagonal boron nitride in 1L of 2mol / L sodium hydroxide solution, put in an ultrasonic wave with an ultrasonic power of 1200W, and react in a reactor at 160°C for 24 hours to prepare an aqueous solution of hydroxylated hexagonal boron nitride; The hydroxylated hexagonal boron nitride aqueous solution was dialyzed in deionized water for 4 days, then frozen with liquid nitrogen, and dried in a freeze dryer for 5 days to obtain the dried hydroxylated hexagonal boron nitride product I;

[0044] (2) disperse 1, 1.2mol 3-(2-bromophenyl) propionic acid containing 1mol hydroxyl in 20mol DMSO, add 1wt% methanesulfonic acid, stir and heat up to 140 ℃ for reaction, calculate the quality of water separation as The end of the reaction; then lower the temperature, filter, wash and dry to obtain the intermediate product II (IR: 3500cm -1 : -OH disappears; 1733cm ...

Embodiment 3

[0049] A preparation method of bio-based lubricating oil base oil, comprising the following steps:

[0050] (1) Disperse 3g of hexagonal boron nitride in 1L of 3mol / L sodium hydroxide solution, put in an ultrasonic wave with an ultrasonic power of 1300W, and react in a reactor at 180°C for 12h to prepare an aqueous solution of hydroxylated hexagonal boron nitride; The hydroxylated hexagonal boron nitride aqueous solution was dialyzed in deionized water for 3 days, then frozen with liquid nitrogen, and dried in a freeze dryer for 4 days to obtain the dried hydroxylated hexagonal boron nitride product I;

[0051] (2) Disperse I, 1.2mol 3-(2-bromophenyl)propionic acid containing 1mol hydroxyl in 20mol DMSO, add 1.5wt% methanesulfonic acid, stir and heat up to 130°C for reaction, calculate the quality of water It is the end point of the reaction; then lower the temperature, filter, wash and dry to obtain the intermediate product II (IR: 3500cm -1 : -OH disappears; 1733cm -1 : -C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com