A kind of polyester resin solid lubricating block and preparation method thereof

A technology of polyester resin and solid lubrication, applied in lubricating compositions, petroleum industry, etc., can solve the problems of accelerated release rate of solid lubricating block, unstable relative size of lubricating block, influence of high temperature resistance, etc., and achieve excellent self-lubricating performance , Conducive to environmental protection, good hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

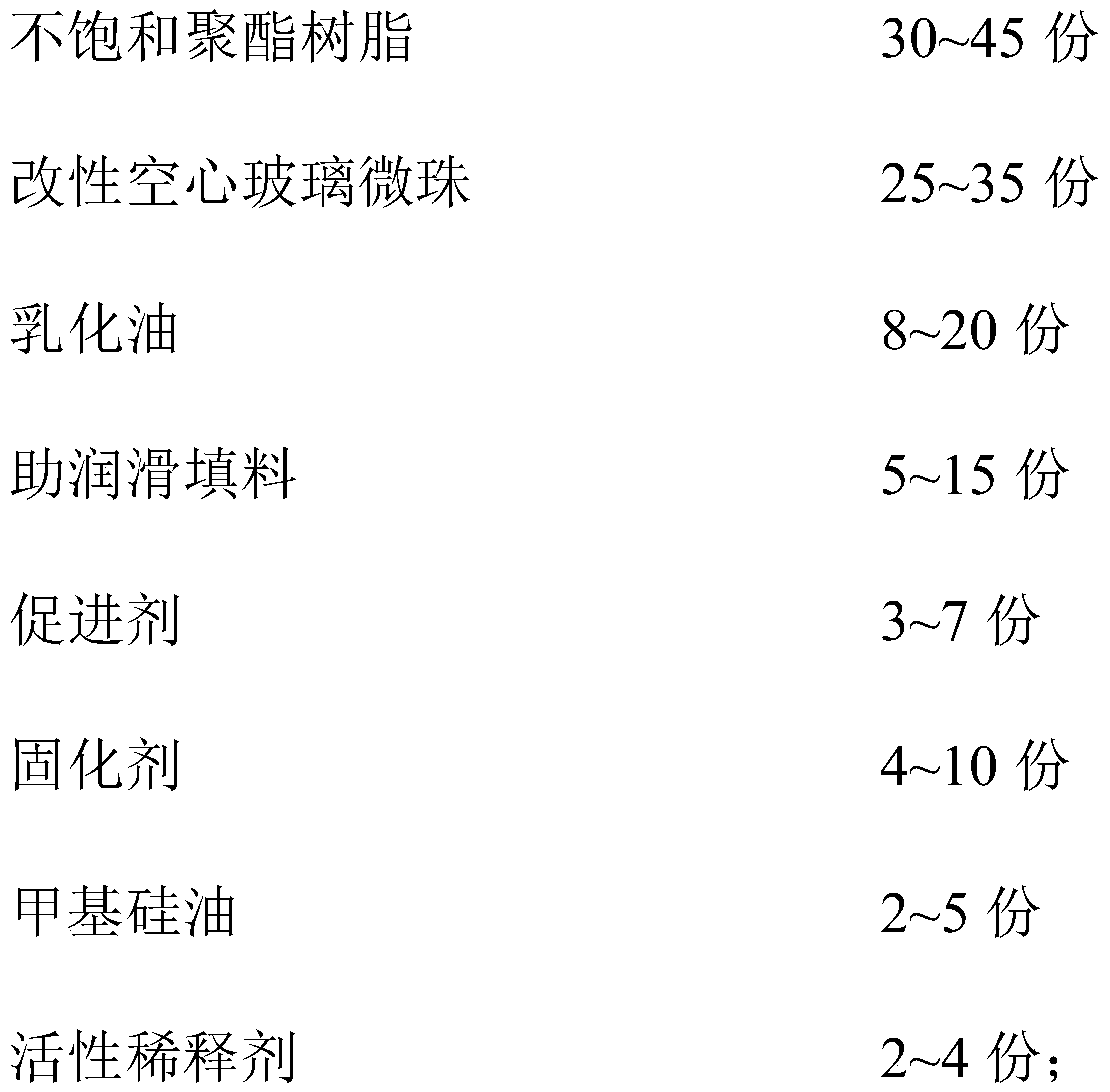

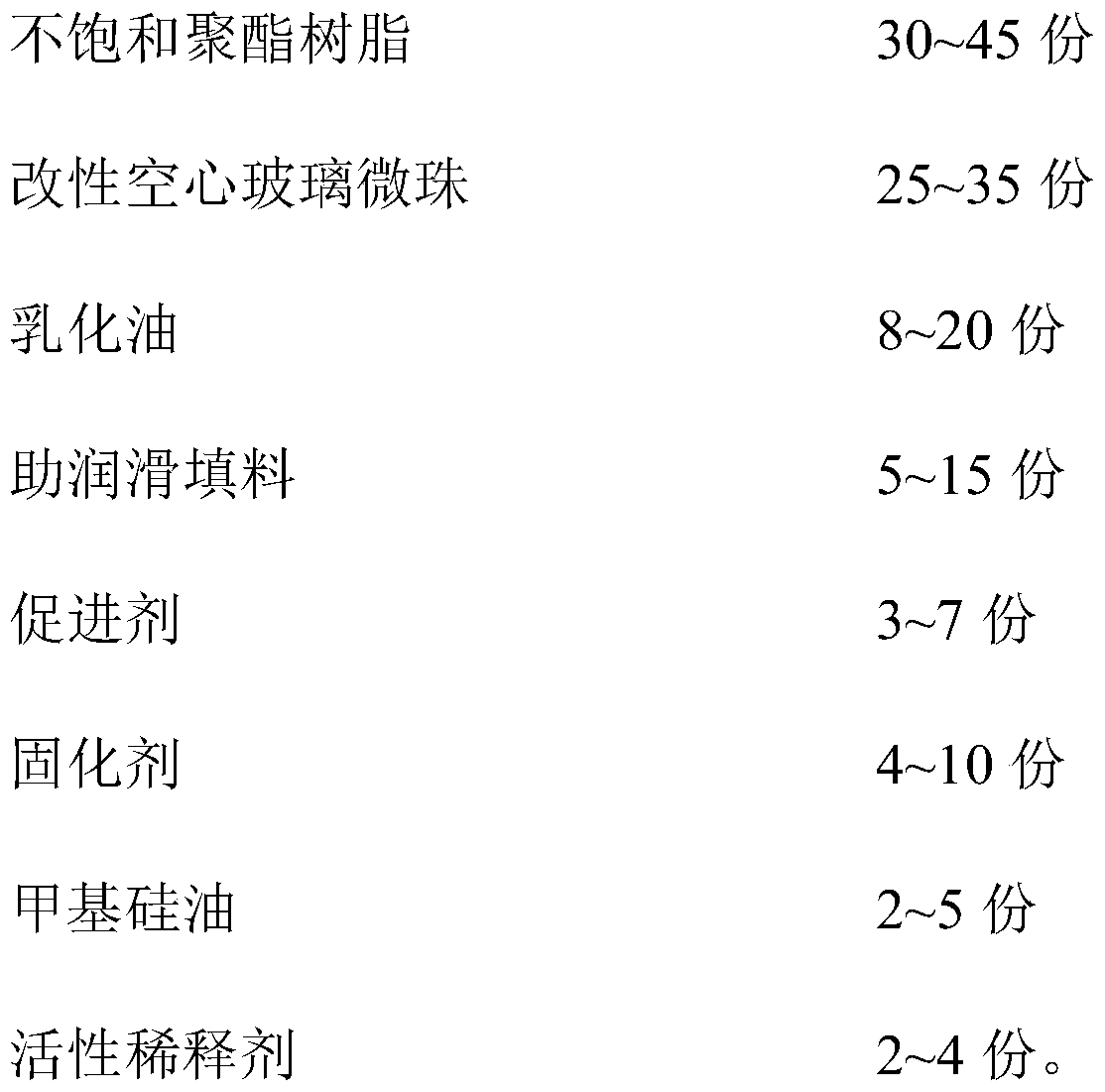

Method used

Image

Examples

Embodiment 1

[0035] (1) Take unsaturated polyester resin 10g, reactive diluent hydroxyethyl acrylate 1g, promotor cobalt isooctanoate 1.0g, the weight ratio of talcum powder, graphite and nano-magnetic particle iron tetroxide three is 8:1: 1, 5g of lubricating filler, 6g of emulsified oil, and 1g of methyl silicone oil.

[0036] (2) Mix the weighed unsaturated polyester resin and lubricating filler evenly, then add methyl silicone oil, active diluent and accelerator and stir evenly with a glass rod.

[0037] (3) Weigh again 10 g of modified hollow glass microspheres, then add 3.33 g of curing agent methyl ethyl ketone peroxide, and mix well.

[0038] (4) Mix the unsaturated polyester resin formula mixed in (3) with emulsified oil.

[0039](5) Apply the release agent to the inner surface of the mold with a brush, and pour the mixture of (4) into the mold to cure at room temperature.

Embodiment 2

[0041] (1) Take unsaturated polyester resin 10g, promotor lead naphthenate 2.0g, reactive diluent hydroxyethyl methacrylate 1g, talcum powder, graphite and nano magnetic particle triiron tetroxide weight ratio are 7.5 :1.5:1 lubricating filler 5g, emulsified oil 6g, methyl silicone oil 0.67g.

[0042] (2) Mix the weighed unsaturated polyester resin and lubricating filler evenly, then add methyl silicone oil, active diluent and accelerator and stir evenly with a glass rod.

[0043] (3) Weigh again 10 g of modified hollow glass microspheres, then add 1.5 g of curing agent benzoyl peroxide, and mix well.

[0044] (4) Mix the unsaturated polyester resin formula mixed in (3) with emulsified oil.

[0045] (5) Apply the release agent to the inner surface of the mold with a brush, and pour the mixture of (4) into the mold to cure at room temperature.

Embodiment 3

[0047] (1) Take by weighing unsaturated polyester resin 10g, reactive diluent trimethylolpropane triacrylate 0.67g, promotor cobalt isooctanoate 1.0g, talc powder, graphite and nano magnetic particle ferric oxide three weight ratios 7:2:1 lubricating filler 2.0g, emulsified oil 6g, methyl silicone oil 1g.

[0048] (2) Mix the weighed unsaturated polyester resin and lubricating filler evenly, then add methyl silicone oil, active diluent and accelerator and stir evenly with a glass rod.

[0049] (3) Weigh again 10 g of modified hollow glass microspheres, then add 1.34 g of curing agent cumene hydroperoxide, and mix well.

[0050] (4) Mix the unsaturated polyester resin formula mixed in (3) with emulsified oil.

[0051] (5) Apply the release agent to the inner surface of the mold with a brush, and pour the mixture of (4) into the mold to cure at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com