A kind of iron-based self-lubricating material and preparation method thereof

A self-lubricating material, iron-based technology, applied in the field of composite materials, can solve problems such as loss of lubrication, achieve excellent lubrication and wear resistance, reduce wear and energy consumption, and excellent self-lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

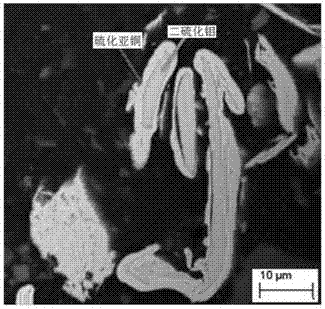

[0022] Prepare an iron-based self-lubricating material with modified molybdenum disulfide as a lubricating component. The chemical composition is as follows: modified molybdenum disulfide accounts for 3%, and the median diameter of molybdenum disulfide is 20 μm; -100 mesh Iron powder accounts for 97%. Its preparation process is as follows:

[0023] (1) Copper plating on the surface of molybdenum disulfide: CuSO 4 ·5H 2 O was added to deionized water to prepare copper sulfate solution, then potassium sodium tartrate and EDTA-2Na were added as complexing agents, sodium hydroxide was used to adjust the pH of the solution, and formaldehyde was added after the solution was heated to the reaction temperature as a reducing agent. molybdenum disulfide, so that the mass fraction of electroless copper plating on its surface is 3% of the mass of molybdenum disulfide, and then mechanically stirred. After the solution is clarified, the reaction is complete, and then the copper-coated mo...

example 2

[0028] An iron-based self-lubricating material with modified molybdenum disulfide as a lubricating component. The chemical composition is as follows: modified molybdenum disulfide accounts for 5%, and the median diameter of molybdenum disulfide is 25 μm; -100 mesh iron powder 95%. Its preparation process is as follows:

[0029] (1) Copper plating on the surface of molybdenum disulfide: CuSO 4 ·5H 2 O was added to deionized water to prepare copper sulfate solution, then potassium sodium tartrate and EDTA-2Na were added as complexing agents, sodium hydroxide was used to adjust the pH of the solution, and formaldehyde was added after the solution was heated to the reaction temperature as a reducing agent. molybdenum disulfide, so that the mass fraction of electroless copper plating on its surface is 5% of the mass of molybdenum disulfide, and then mechanically stirred. After the solution is clarified, the reaction is complete, and then the copper-coated molybdenum disulfide pa...

example 3

[0034] An iron-based self-lubricating material with modified molybdenum disulfide as a lubricating component. The chemical composition is: modified molybdenum disulfide: 5%, the median diameter of molybdenum disulfide is 15 μm; -100 mesh 316L stainless steel powder 95%. Its preparation process is as follows:

[0035] (1) Copper plating on the surface of molybdenum disulfide: CuSO 4 ·5H 2 O was added to deionized water to prepare copper sulfate solution, then sodium potassium tartrate and EDTA-2Na were added as complexing agents, sodium hydroxide was used to adjust the pH of the solution, and formaldehyde was added after the solution was heated to the reaction temperature as a reducing agent. Molybdenum disulfide of suitable mass is added so that the mass fraction of electroless copper plating on its surface is 6% of the mass of molybdenum disulfide, and then mechanically stirred. After the solution is clarified, the reaction is complete, and then the copper-coated molybdenu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com