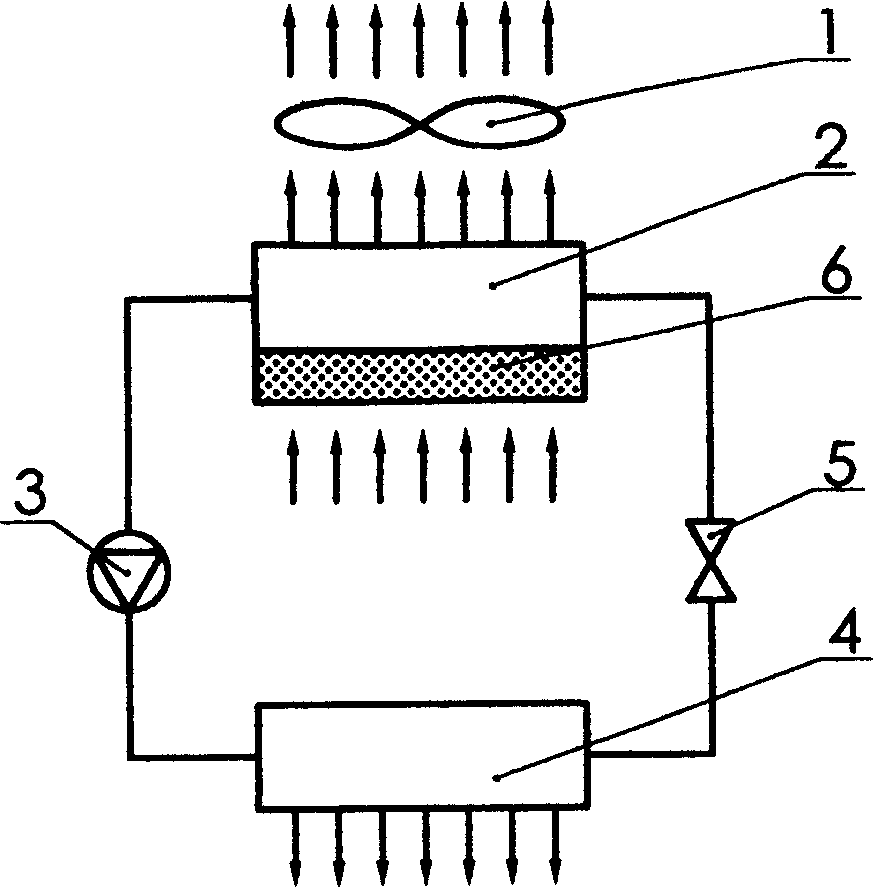

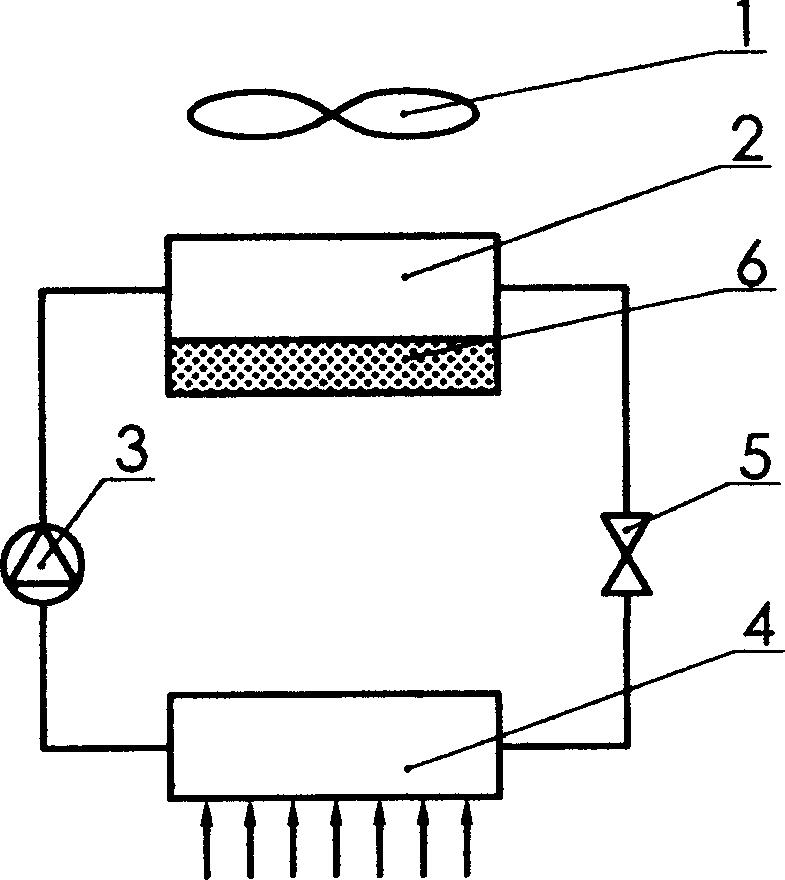

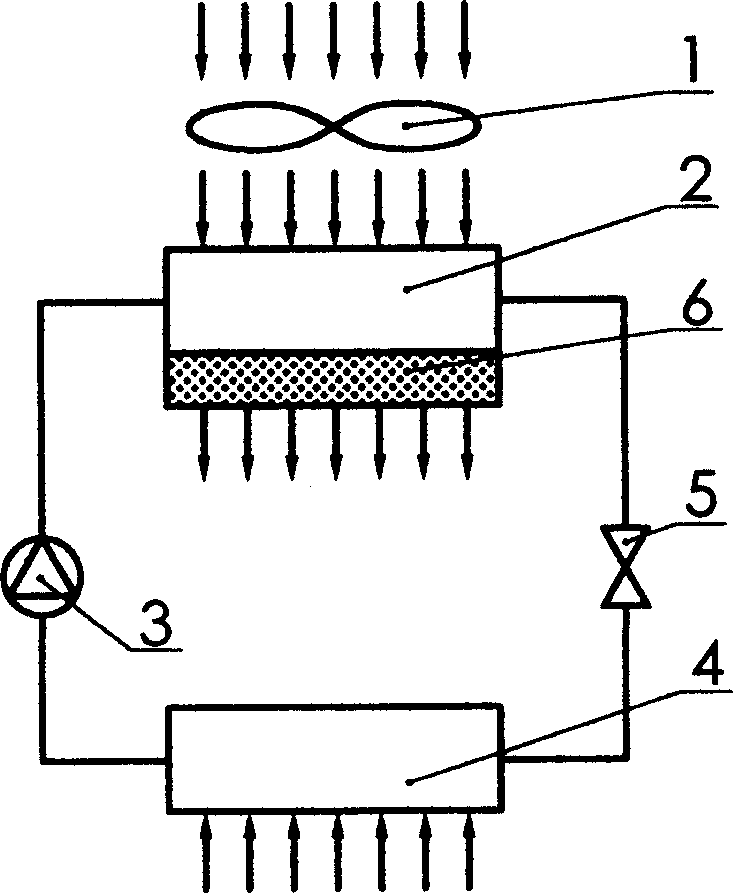

Defrosting device of air heat exchanger

A technology for heat exchangers and fans, which is applied in the field of defrosting devices for air heat exchangers, and can solve problems such as affecting the defrosting effect, reducing the surface temperature of the heat exchanger, and the heat exchanger cannot be forced to cool when the fan is turned off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0026] Install a circuit to start (or stop) the forward and reverse of the fan in the air-cooled refrigerator, such as Figure 4 , Figure 5 . in Figure 4 It is the electrical schematic diagram of starting (or stopping) forward and reverse fan for ordinary three-phase asynchronous motor through the switching of AC contactor and exchanging two-phase power supply. refer to Figure 4 : When the normally open contact [2k] of the fan motor AC contactor [2] is disconnected and the normally open contact [1k] of the fan motor AC contactor [1] is closed, the fan motor [3] is energized and rotates forward, and When the normally open contact [1k] of the fan motor AC contactor [1] is disconnected and the normally open contact [2k] of the fan motor AC contactor [2] is closed, the fan motor [3] is energized and reversed. Figure 5 It is the electrical schematic diagram of starting (or stopping) the forward and reverse fan for the single-phase motor through the switching of the AC conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com