Heater of heat recovery for asphalt pavement

A technology of asphalt pavement and thermal regeneration, applied in the direction of roads, roads, road repair, etc., can solve the problems of poor heating quality, poor safety, general quality, etc., and achieve the effect of increasing the heating rate, the heat transfer rate, and the high economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

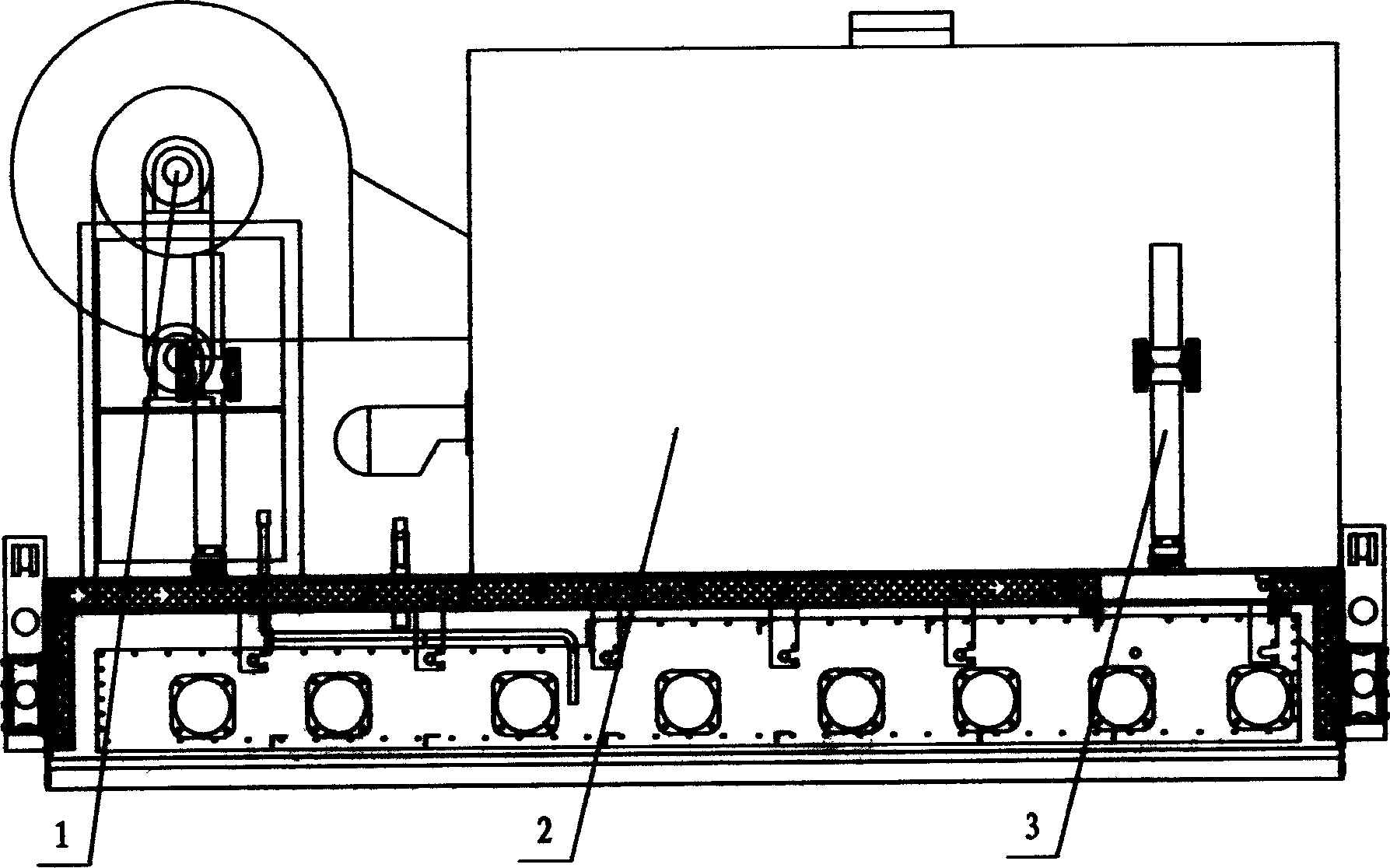

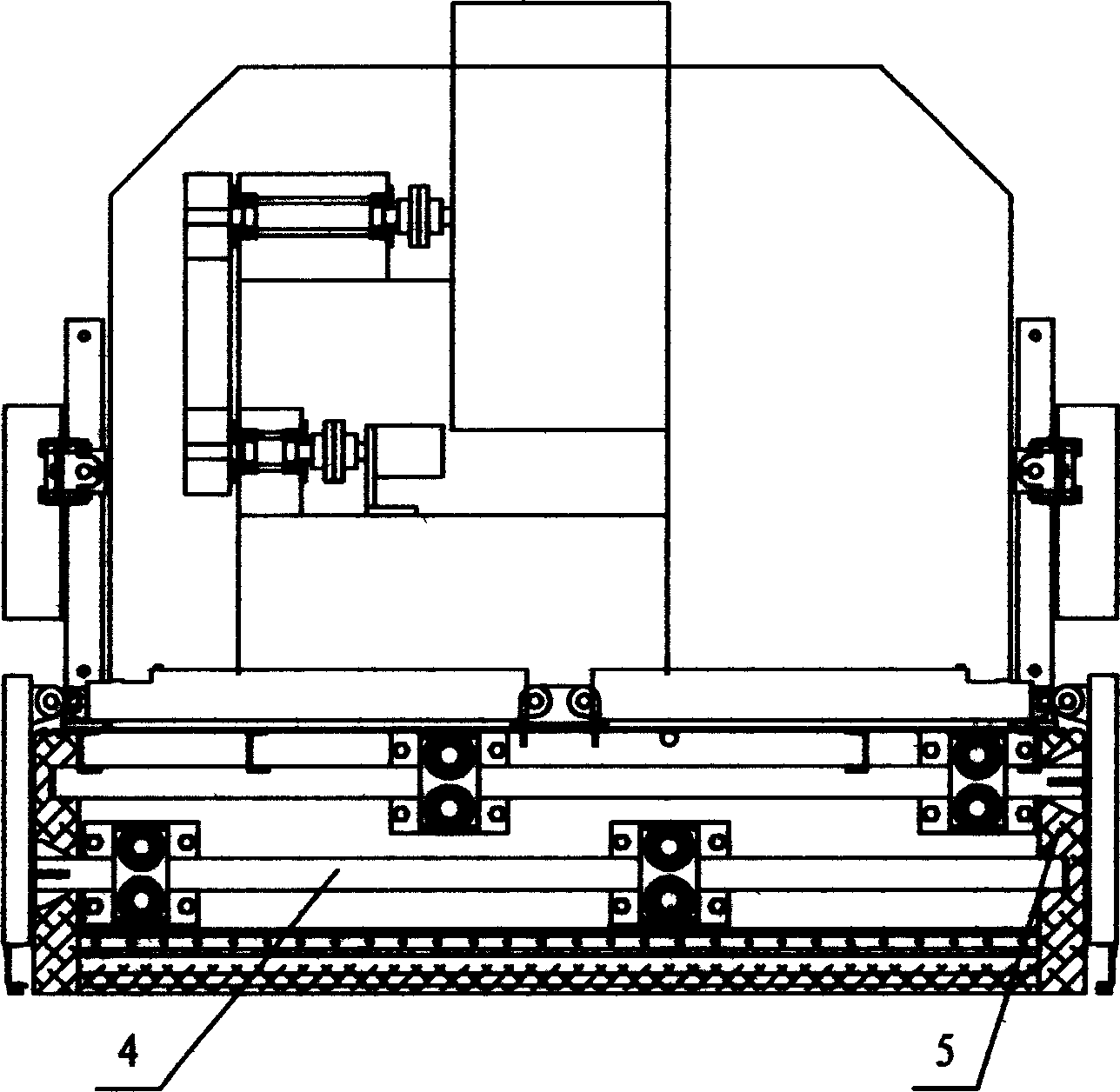

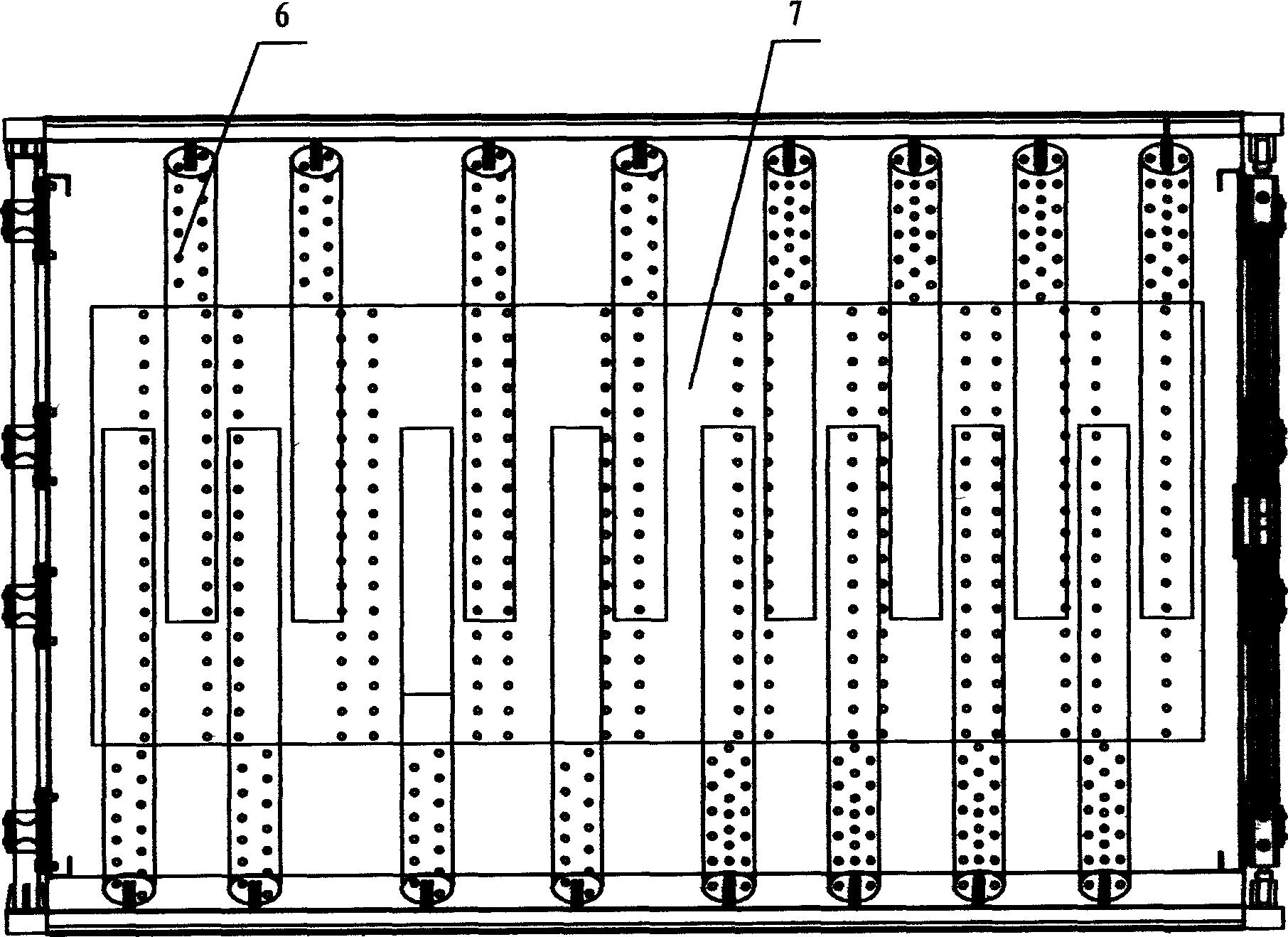

[0016] Such as figure 1 , 2 , 3, the asphalt pavement thermal regeneration heater is characterized in that: the circulating fan 1 is located next to the hot blast boiler 2, the heating box 7 hangs under the hot blast boiler 2, the lifting mechanism 3 is placed in front of the hot blast boiler 2, and the box cover 5 covers Outside the heating box 7, one end of the telescopic heating tube 6 is connected with the heating box 7, and the other end is connected with the telescopic mechanism 4. The heating box 7 is composed of several rows of injection holes distributed according to the law of asphalt concrete heat conduction, which can realize the heating function of the asphalt concrete road surface. Telescopic heating pipe 6 Each heating pipe has several rows of injection holes distributed according to the heat conduction law of asphalt concrete according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com