Two constant singlechambered balanced container

A technology for balancing containers and heating components, which is applied in the direction of displaying liquid level indicators through pressure measurement, components of steam boilers, steam boiler accessories, etc., which can solve the problem of large correction errors of the average temperature of the reference water column, unstable measurement, and unfavorable safety Stable operation and other problems, to achieve the effect of small measurement error, simplified setting and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

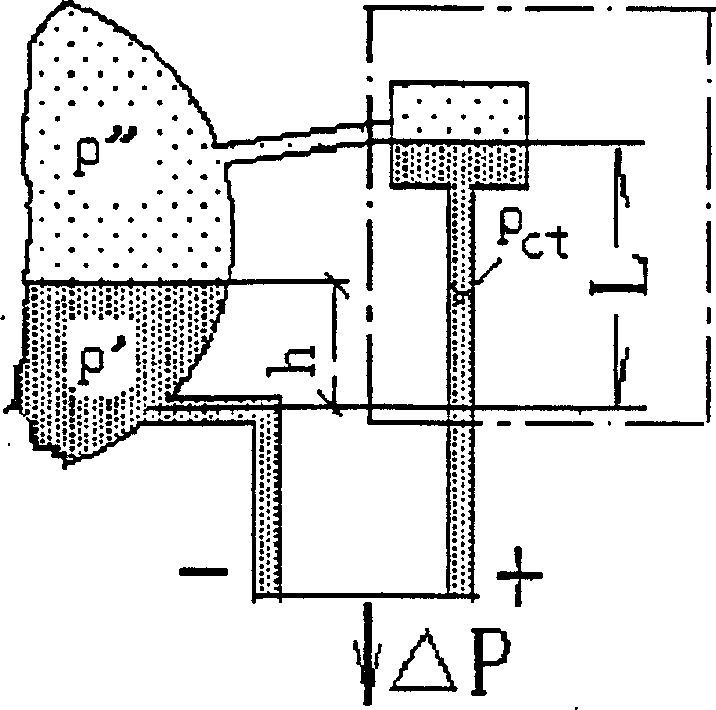

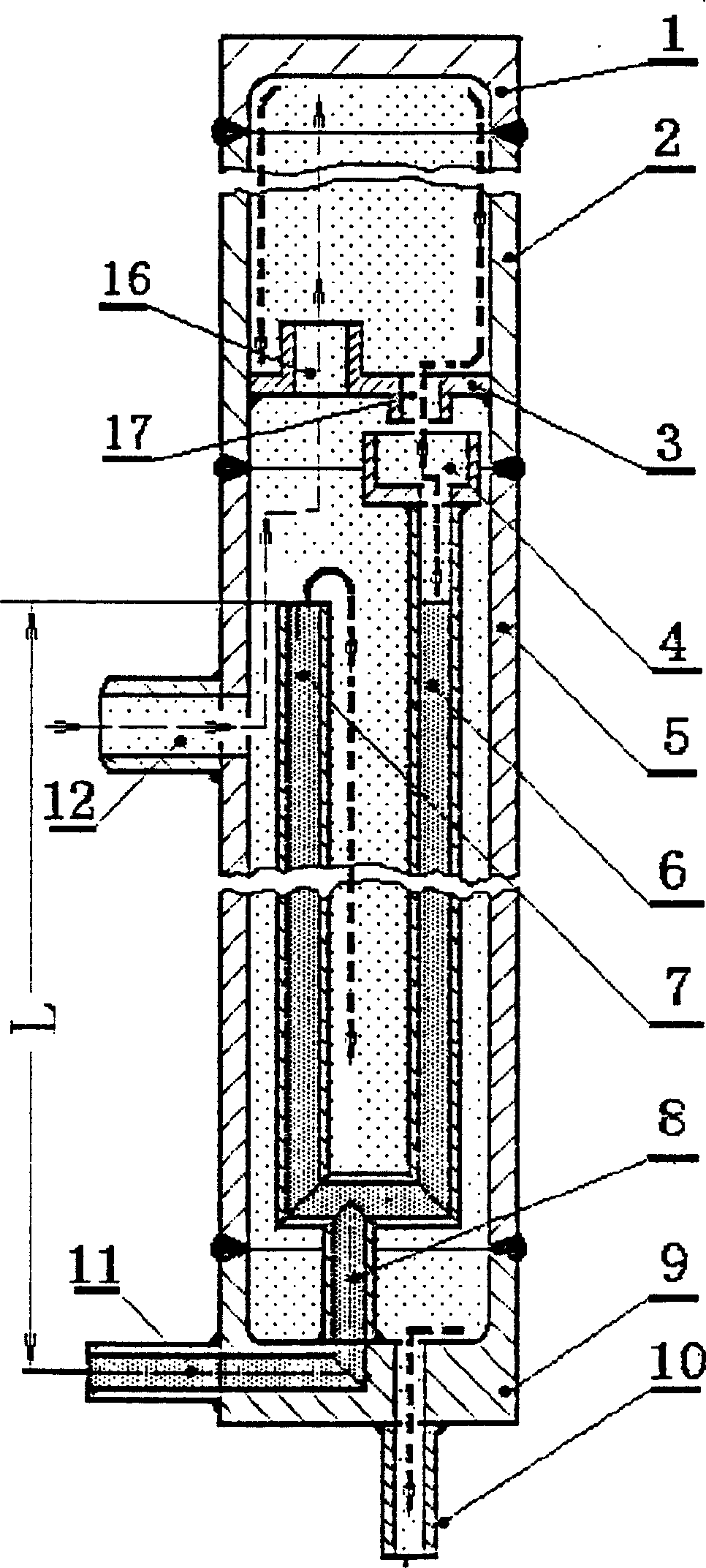

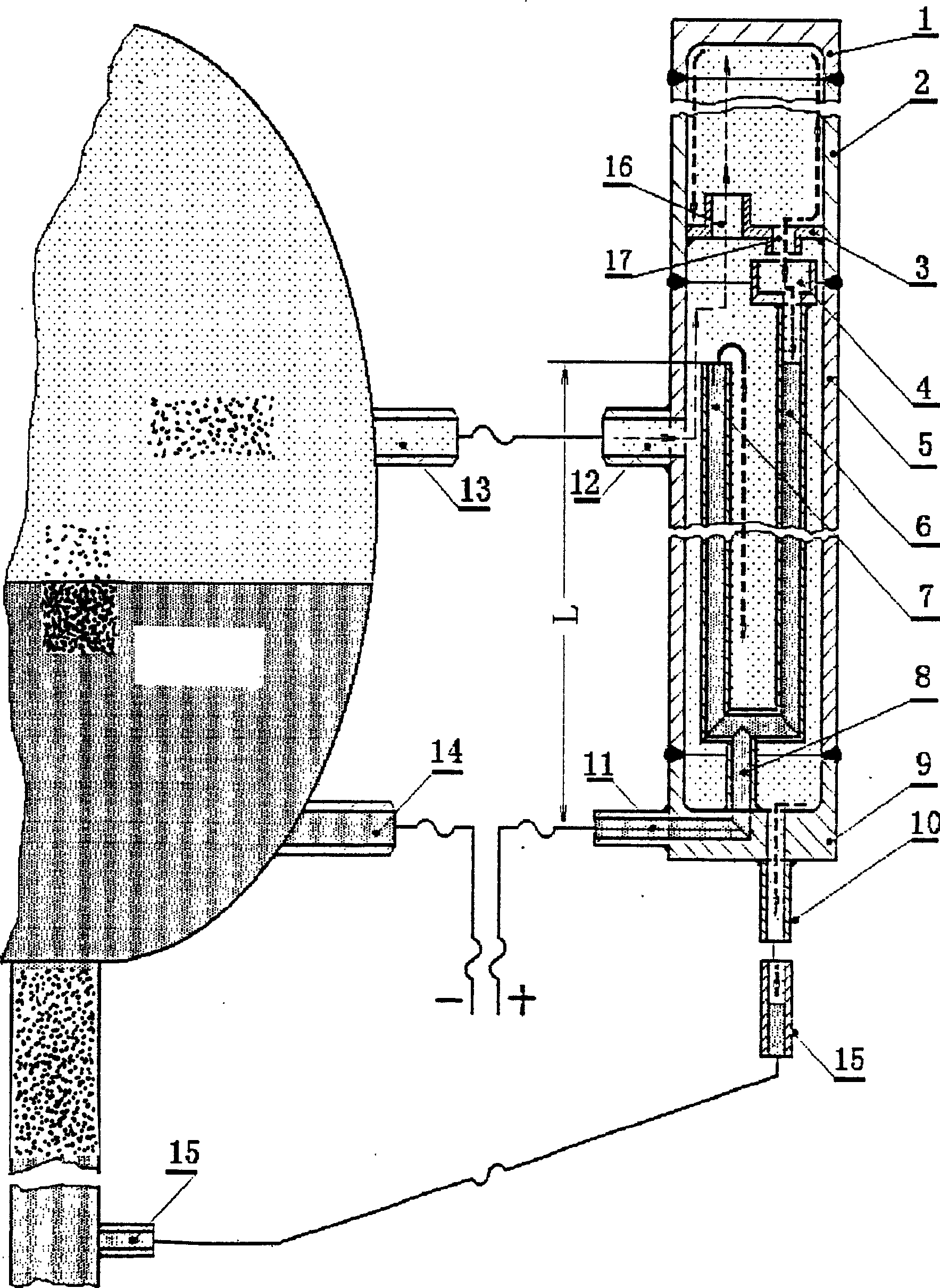

[0016] Now in conjunction with accompanying drawing for further description:

[0017] The balance container of the present invention is mainly composed of a tuning fork tubular assembly, a heating assembly, and an extension condensing assembly. The tuning fork tubular assembly is located in the heating assembly, and the extension condensing assembly is connected to the upper position of the heating assembly; Water injection pipe 6, water cup 4, reference pipe 7, fork handle pipe 8 are formed. The reference pipe is shorter than the water injection pipe, and the reference pipe is connected with the water injection pipe to form a U-shaped pipe of unequal height. The bottom hole of the U-shaped pipe is connected with the fork handle pipe, and the reference pipe and the fork handle pipe form a reference water column pipe. 4 links to each other with water injection pipe 6. (2) The heating assembly is mainly composed of the lower cylinder 5 and the lower plug 9. The steam inlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com