Reparation method for water channel and dockage channel of water power station

A repair method and technology of hydropower stations, which are applied in the fields of hydropower stations, infrastructure repair, hydropower generation, etc., and can solve problems such as endangering the safety of dams, affecting hydraulic structures such as flood discharge, sand discharge, power generation, and restoration quality cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

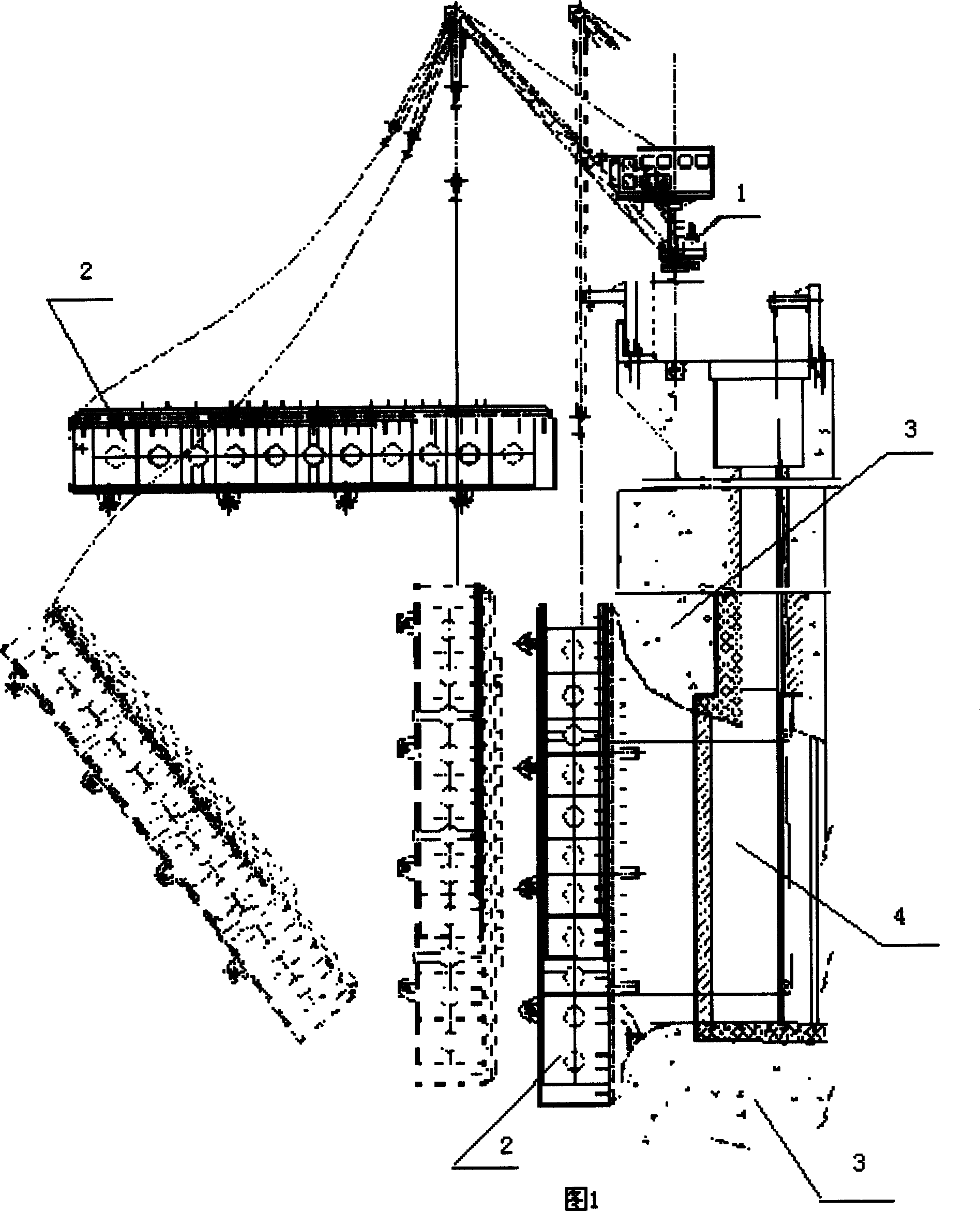

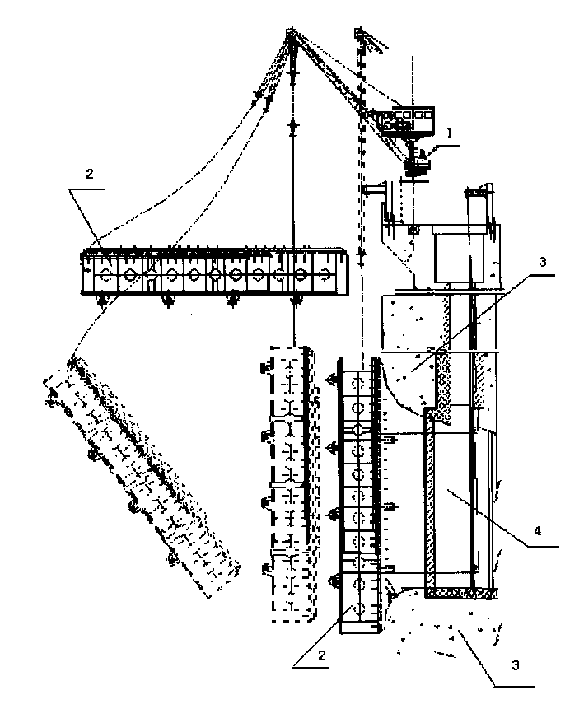

[0018] Embodiment as shown in Figure 1: Figure 1 is a schematic diagram of the motion state when the floating body gate 2 of the embodiment is installed to the opening 4 of the dam body 3 with a crane 1, the floating body gate 2 will be welded or bolted on the spot with the door leaf structure manufactured in sections It is connected into an integral sealed box structure, and the floating body gate structure is a sealed box structure, in which there are independent sealed cabins for adjusting balance, not connected to each other, filling, drainage and filling and exhaust pipelines, water injection cabins and empty cabins, The empty cabin is fixed on the upper part of the floating body gate, and the water injection cabin is fixed on the lower part of the floating body gate 2; the empty cabin makes the buoyancy of the floating body gate 2 in water greater than its own gravity; The % gate thickness is surfaced so that other accessories on the gate can be installed. There are 5 wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com