Coin finished product and semifinished product arrangement and inversion machine

A technology of semi-finished products and flipping machines, which is applied in the direction of coin inspection, handling coins or valuable banknotes, automatic packaging control, etc. and turn over, put an end to overlapping coins, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

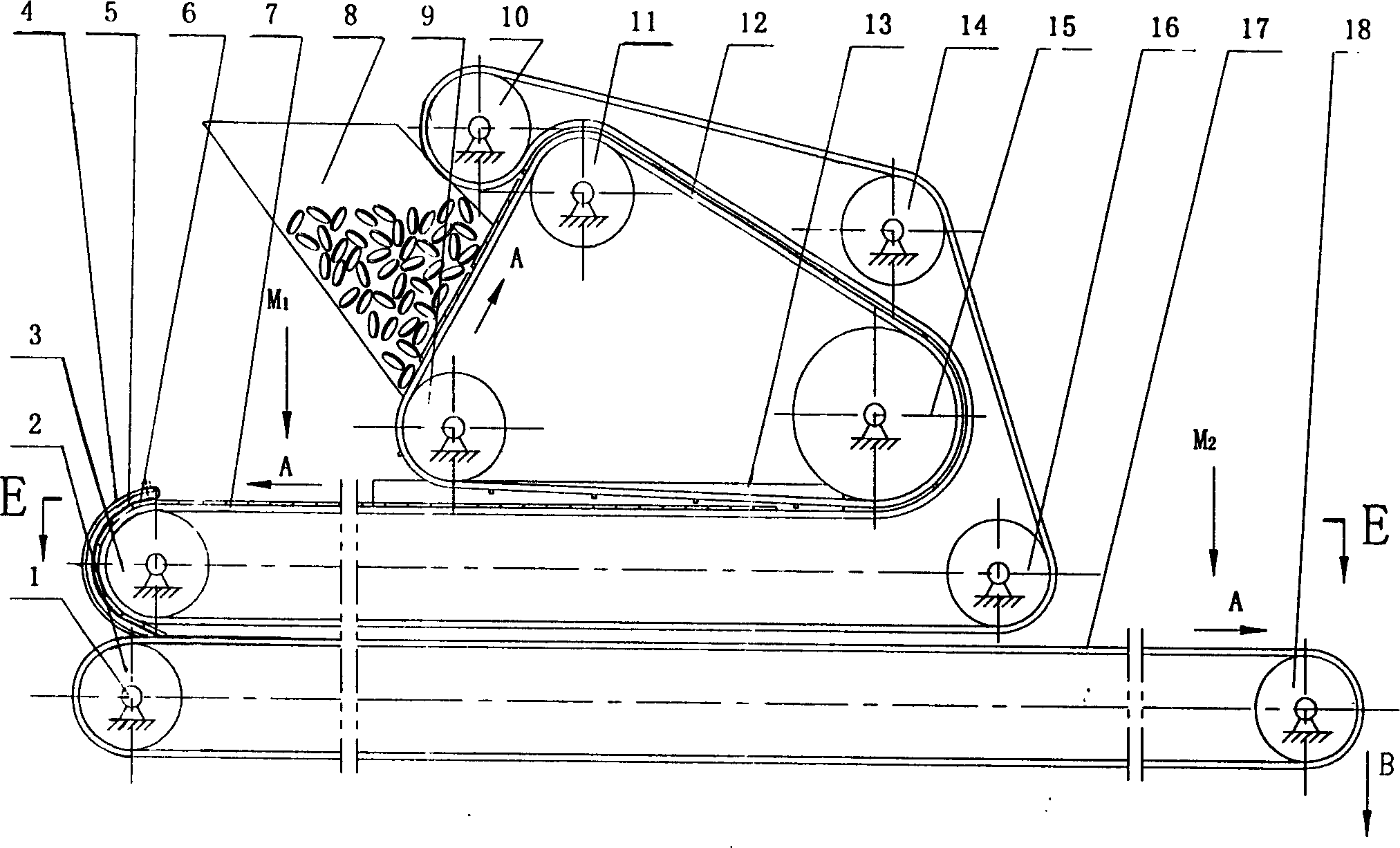

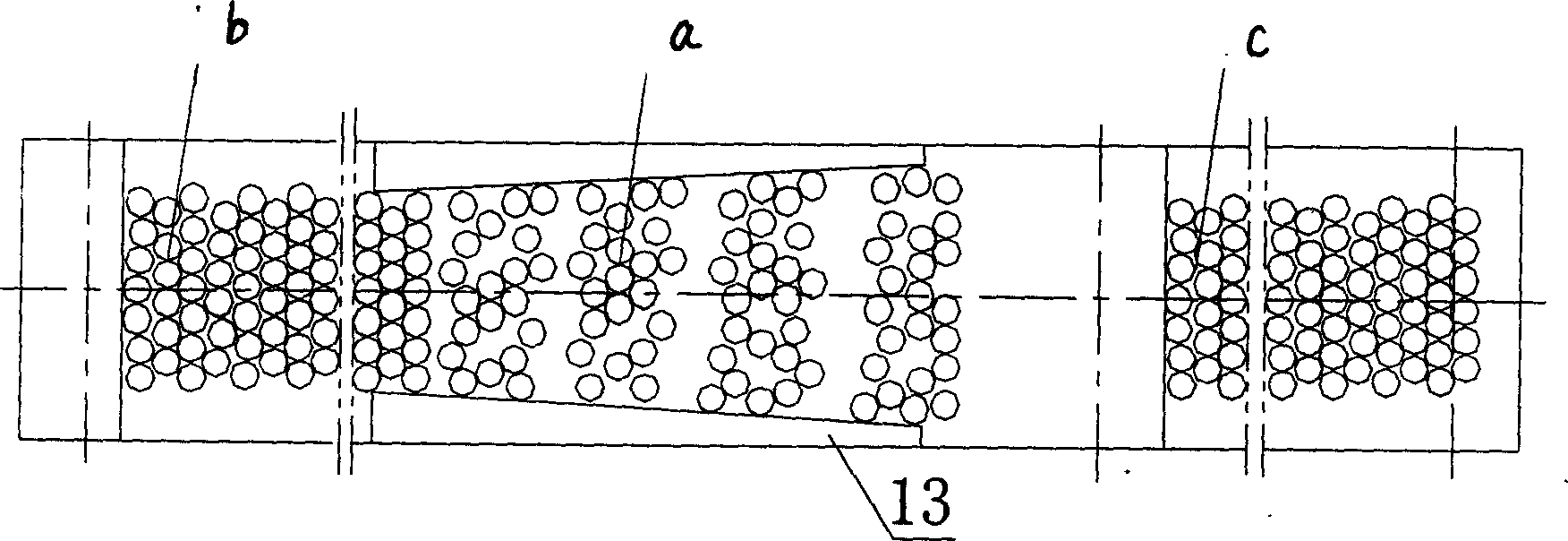

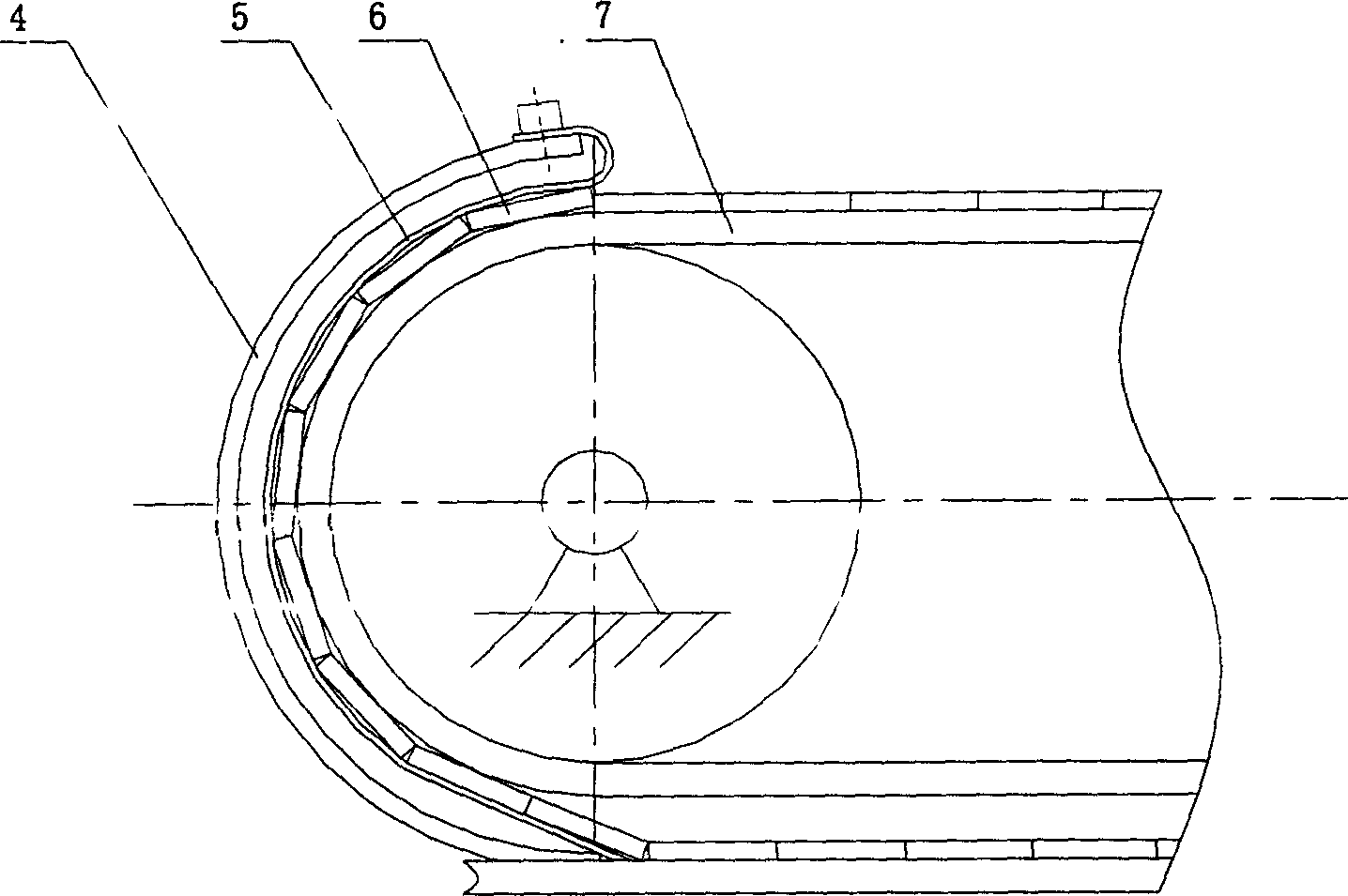

[0014] The coin finished product of the present embodiment and semi-finished product are arranged and turned over machine such as figure 1 , 2 , 3, the main components are driving rollers (electric rollers) 3, 11, 18, driven rollers 2, 9, 10, 14, 15, 16 and semicircular pressure plates 4, thin metal sheets (0.3 mm thick elastic copper skin) 5, cargo bucket 8, inclined block 13, frame 1, first conveyor belt 12, second conveyor belt 7, third conveyor belt 17. Wherein, the driving roller 18, the driven roller 2 and the conveyor belt 17 form a translation conveyor belt surrounding the two rollers; the driving roller 11, the driven rollers 9, 15 and the conveyor belt 12 form a triangle-shaped circular conveyor belt, And the conveyor belt 12 is shaped on the transverse ribs distributed at intervals; the driving roller 3, the driven rollers 10, 14, 16 and the conveyor belt 7 form a C-shaped circular conveyor belt. One side of the triangle surrounding the conveyor belt 12 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com