Upper electrode and plasma processing device

A plasma and electrode technology, applied in the direction of plasma, circuit, discharge tube, etc., can solve the problems of poor thermal conductivity and difficult temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings;

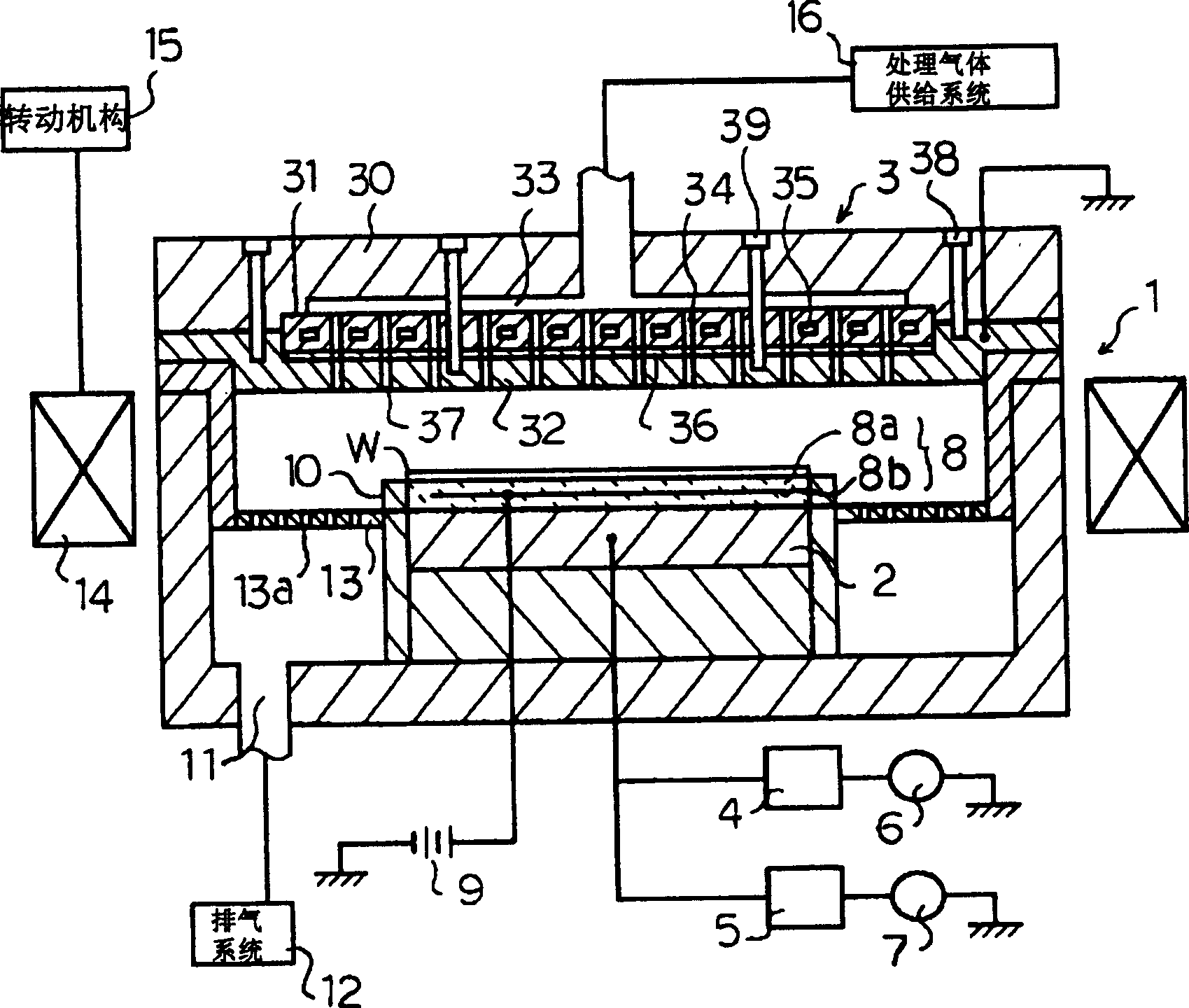

[0030] figure 1 A schematic configuration of an embodiment of the present invention applied to a plasma etching apparatus for etching a semiconductor wafer is schematically shown. In this figure, reference numeral 1 denotes a cylindrical vacuum chamber made of a material such as aluminum and having a hermetically sealed interior.

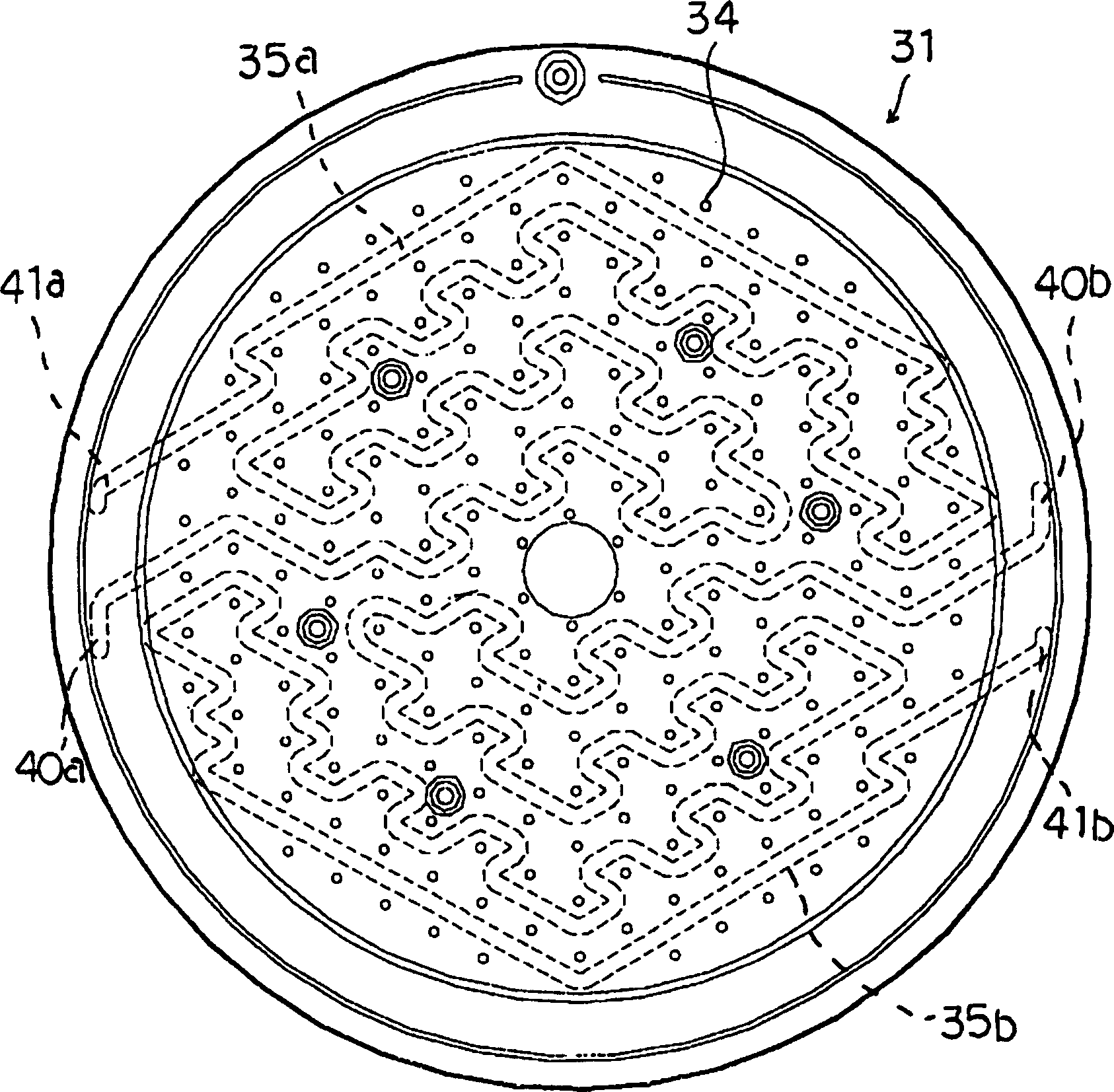

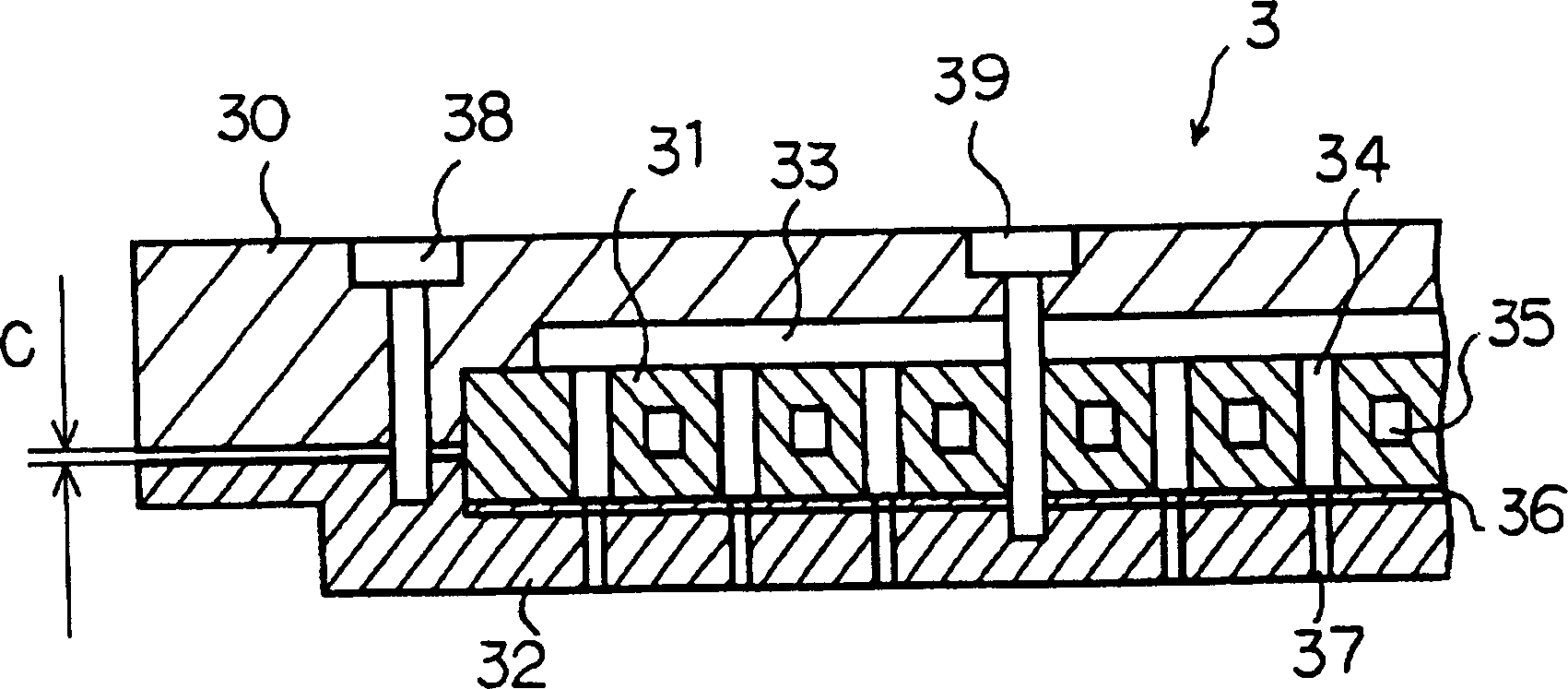

[0031] In this vacuum chamber 1, a stage 2 on which a semiconductor wafer W is placed is provided, and this stage 2 also serves as a lower electrode. In addition, on the top of the vacuum chamber 1, an upper electrode 3 constituting a shower head is provided. A pair of parallel plate electrodes is formed by the mounting table (lower electrode) 2 and the upper electrode 3 . The structure of the upper electrode 3 will be described in detail later.

[0032] Two high-frequency power sources 6, 7 are connected to the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com