Ultrasonic-actuator driving apparatus and ultrasonic-actuator driving method

A technology of a driving device and a driving method, which can be applied to the parts of piezoelectric devices or electrostrictive devices, piezoelectric effect/electrostrictive or magnetostrictive motors, device parts, etc., can solve the position stop accuracy Deterioration, deviation of moving state, high retention force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0031] [structure]

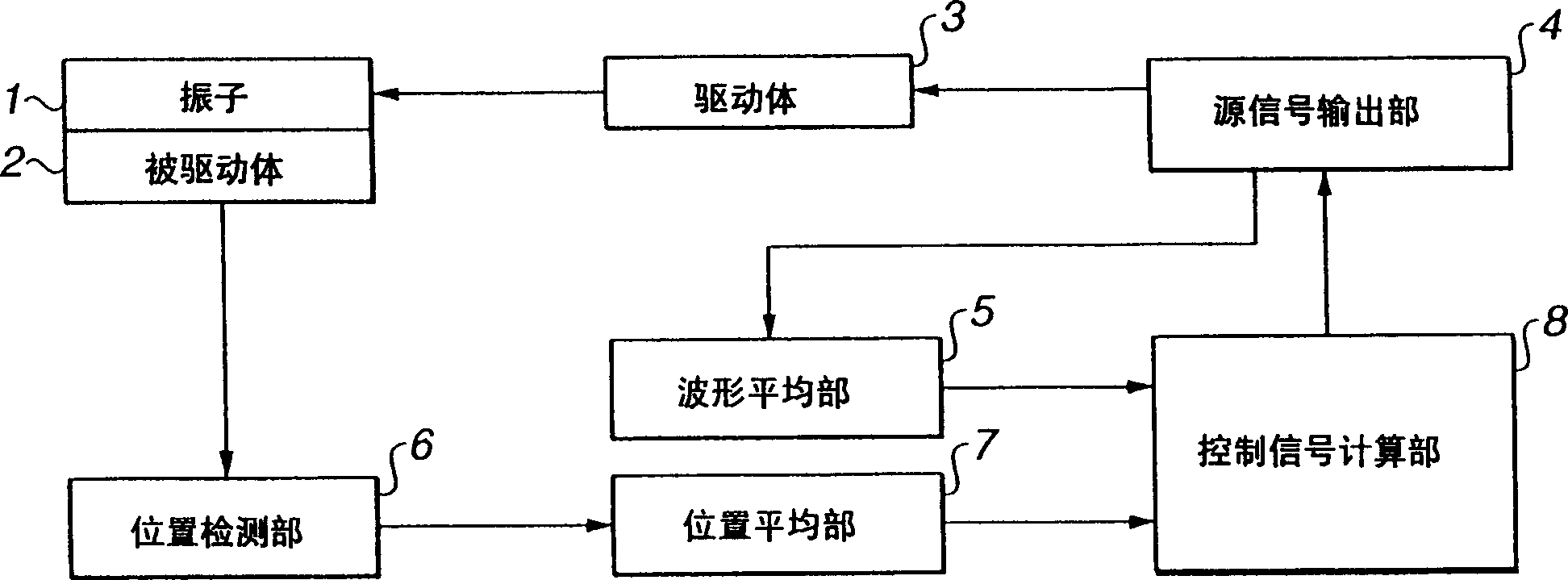

[0032] figure 1 Showing the first embodiment of the ultrasonic actuator driving device of the present invention, it is a block diagram showing the overall structure of the device.

[0033] Ultrasonic actuator driving device of the present invention such as figure 1 As shown, its structure includes: the vibrator 1 and the driven body 2 constituting the ultrasonic actuator, the driving part 3, the source signal output part 4, the waveform averaging part 5, the position detecting part 6, the position averaging part 7 and the control signal calculation part 8.

[0034] To further describe, an ultrasonic actuator is provided in which a driven body 2 in contact with a vibrator 1 is frictionally driven; and a drive unit 3 is electrically connected to the vibrator 1 of the ultrasonic actuator. The drive unit 3 applies a cyclic voltage to the vibrator 1 .

[0035] The active signal output unit 4 is electrically connected to the drive unit 3 . The source signal...

no. 2 example

[0050] [structure]

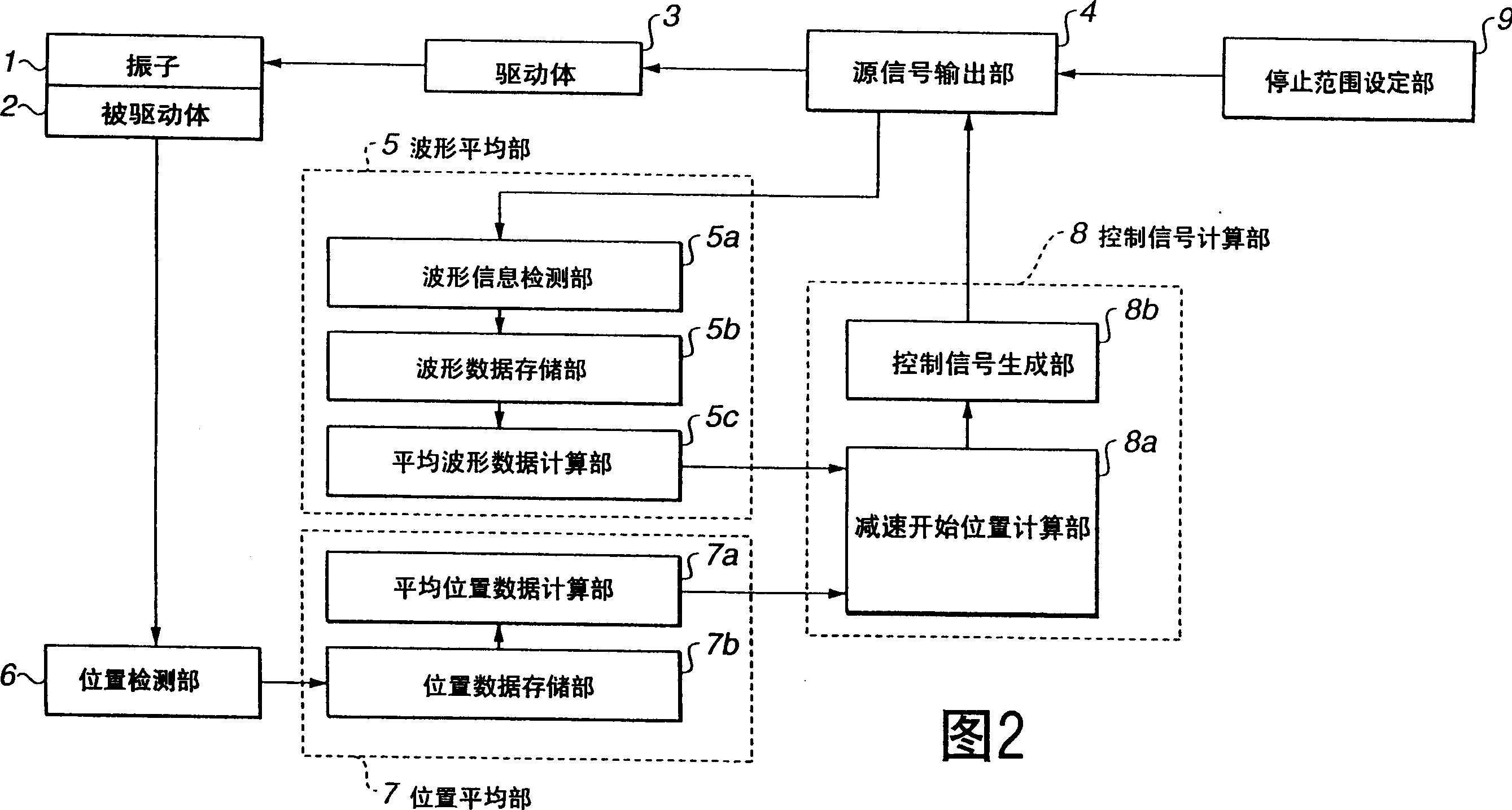

[0051] Fig. 2 shows a second embodiment of the ultrasonic actuator driving device of the present invention, and is a block diagram showing the overall structure of the device. In addition, in FIG. 2, the same symbols are attached to the same constituent elements as those of the apparatus of the first embodiment described above, and description thereof will be omitted, and only different parts will be described.

[0052] In the ultrasonic actuator driving device of this embodiment, the difference from the above-mentioned first embodiment is that, in order to realize driving control for higher precision and stable positioning, the waveform averaging unit 5 and the position averaging unit are configured in more detail. 7 and the control signal calculation part 8, and a stop range setting part is set.

[0053] As shown in FIG. 2 , the waveform average unit 5 includes a waveform information detection unit 5 a, a waveform data storage unit 5 b, and an average w...

no. 3 example

[0082] [structure]

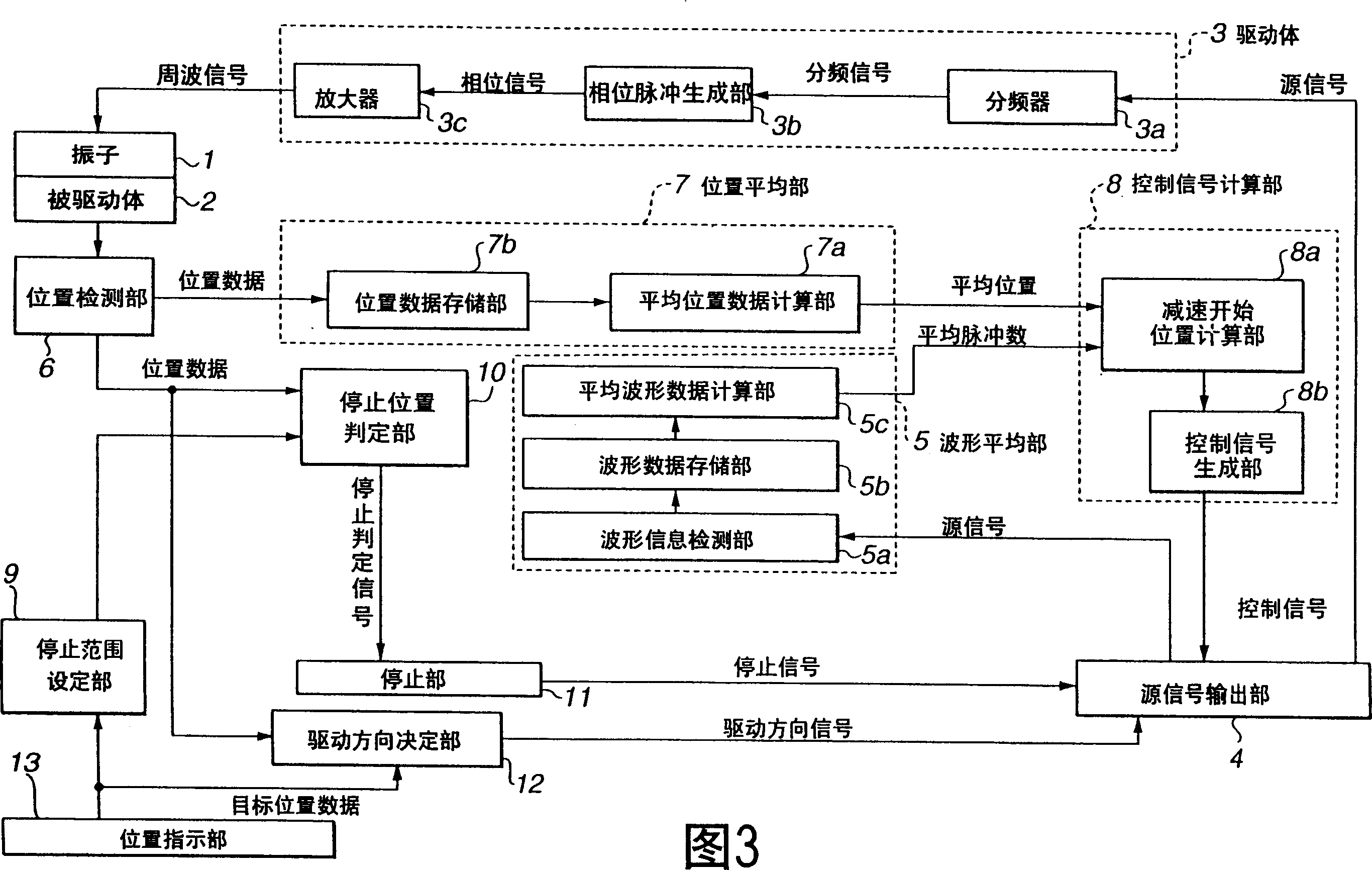

[0083] Figure 3 and Figure 4A to Figure 4C A third embodiment of the ultrasonic actuator driving device of the present invention is shown. Fig. 3 is a block diagram showing the overall structure of the device, Figure 4A to Figure 4C is a flow chart for explaining the ultrasonic actuator driving method of the present invention applied to the device, Figure 4A is the main initial setting processing routine, and Fig. 4B is the control process processing routine, Figure 4C Yes indicates that the process processing routine is stopped. Furthermore, in FIG. 3 , the same structures as those of the apparatuses of the first and second embodiments above are denoted by the same symbols, their descriptions are omitted, and only the different parts are described.

[0084] The ultrasonic actuator driving device of this embodiment is characterized in that, in order to realize drive control for high-precision and stable positioning, on the basis of the components o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com