Composite life-saving float and its producing method

A manufacturing method and floating core technology, which are used in ship construction, ships, foldable/inflatable hulls, etc., can solve the problems of unstable quality, low strength, easy corrosion, etc., and achieve reliable performance, improved performance, and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

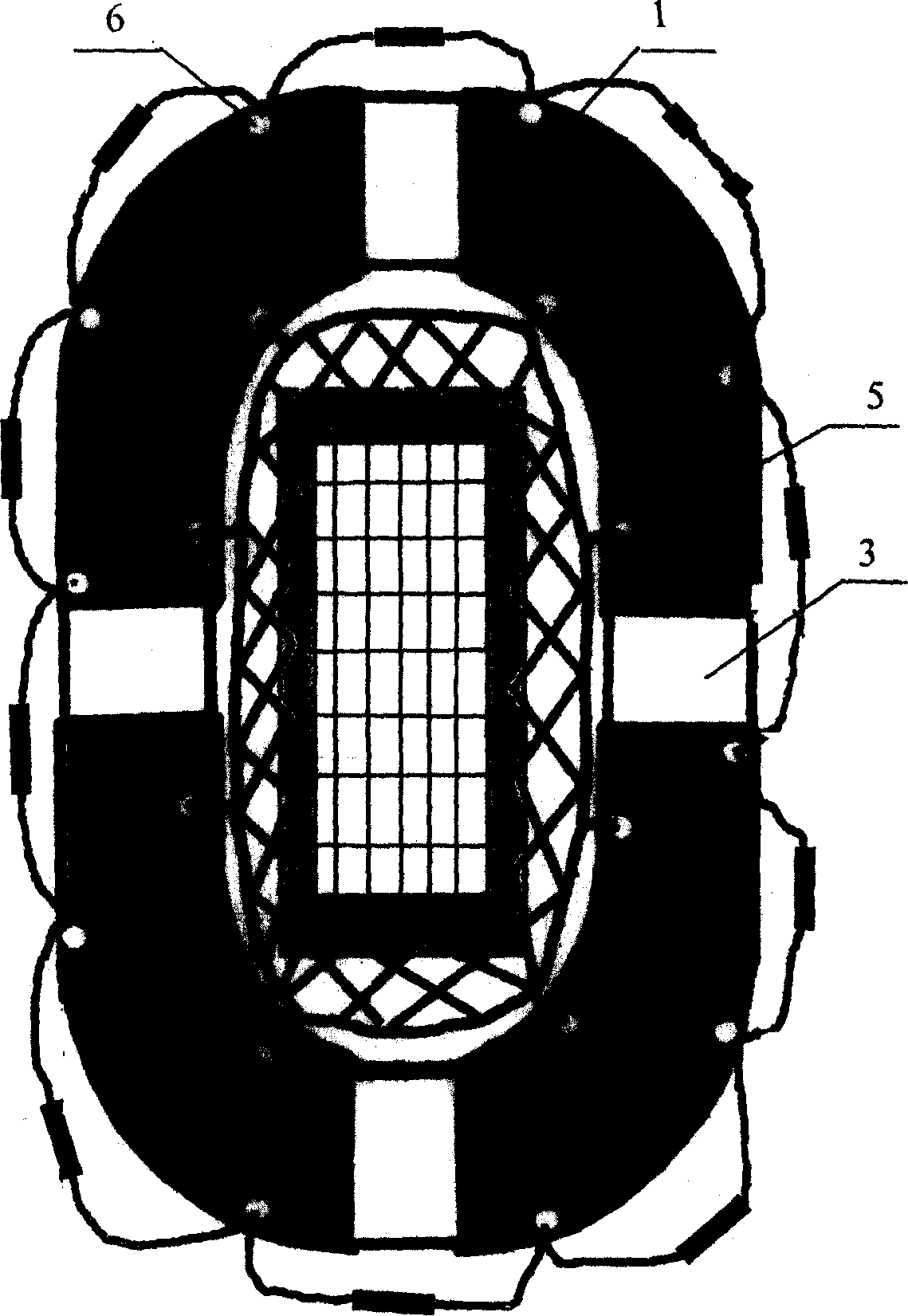

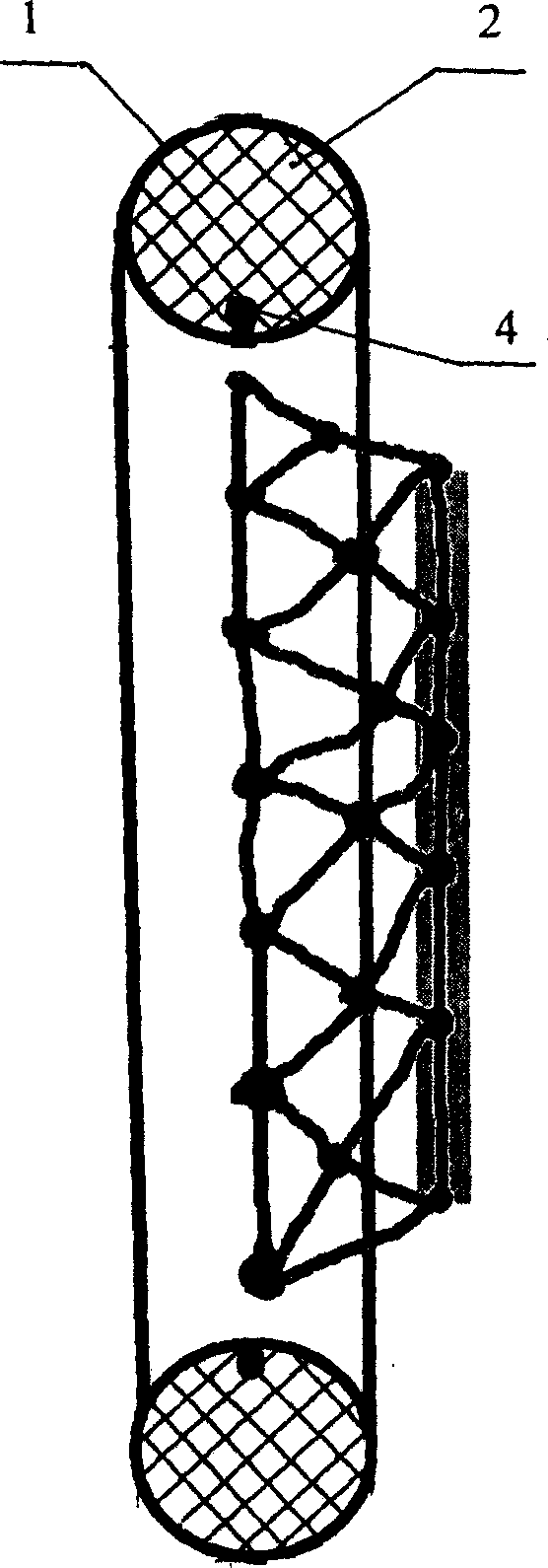

[0020] The composite lifesaving buoy designed by the present invention includes a shell 1 and a floating core 2. The shell 1 is extruded from high-density polyethylene through a plastic extruder. The shell is composed of four sections (or two sections), and the two ends of each section It is designed so that the diameter of one end is larger than that of the other end and can form a tight fit with each other. The four sections of shells are fitted together to form a complete lifesaving buoy. Rivets are used to fix (or glued) the joints between two adjacent sections, and four evenly distributed grooves 3 for mounting reflective materials (the grooves can be six or eight) are arranged on the housing. The shell is provided with reinforcing ribs 4 bundled with metal ropes. The rigid polyurethane foam is injected into the shell and foamed on site to form the buoyant core 2 .

[0021] When manufacturing the housing with an extruder and a mould, the inboard of the housing is prefabr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com