Measuring device for concrete shrinkage and stress

A measuring device, concrete technology, applied in the direction of material inspection products, etc., to achieve the effect of simple structure, small elastic deformation and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

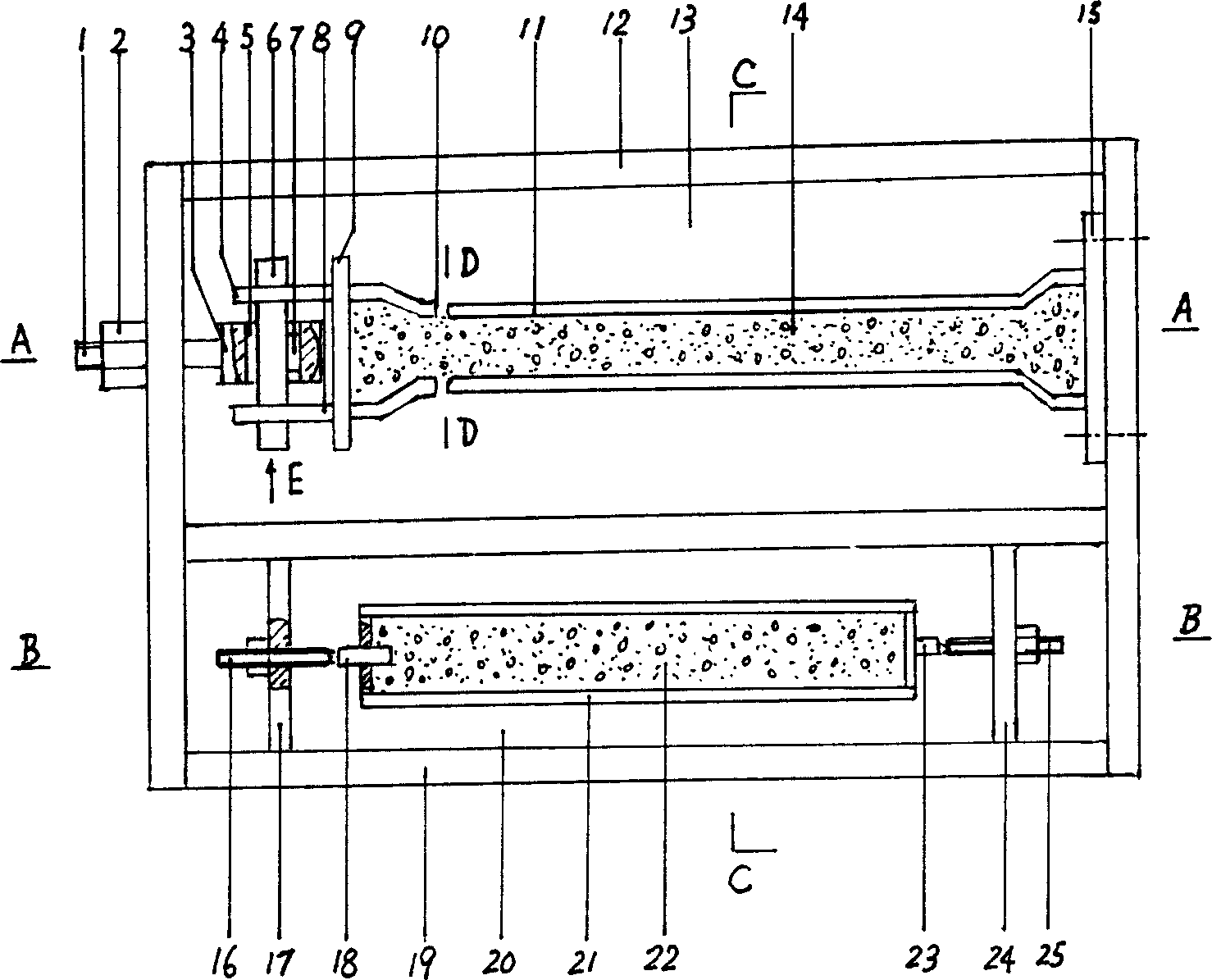

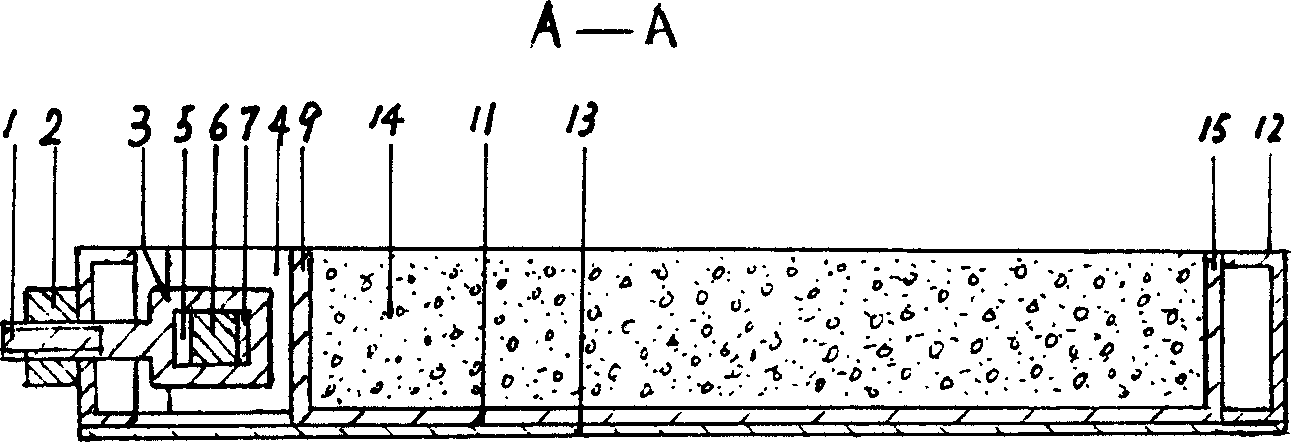

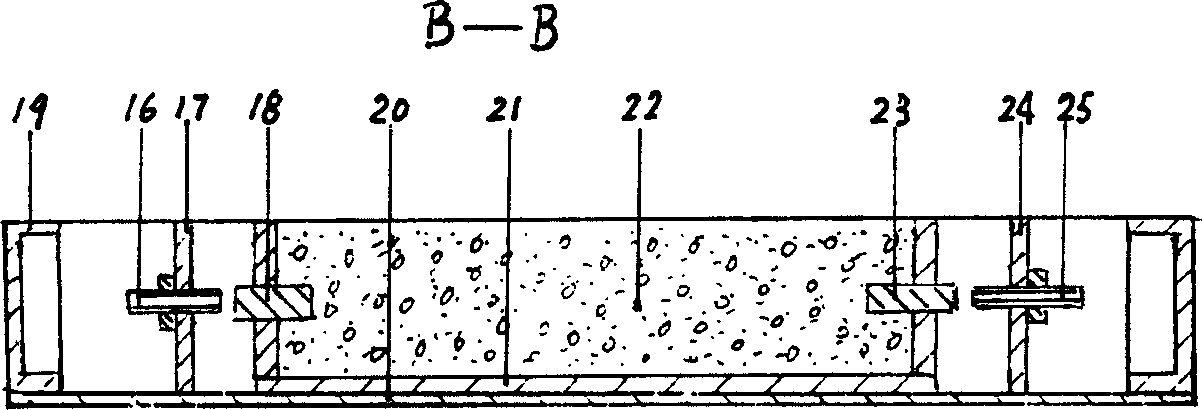

[0014] Such as figure 1 As shown, two rectangular frames (12) (19) are welded by channel steel, steel plates (13) (20) are welded under the frame, and the mold (11) and mold (11) for measuring the concrete stress are placed in the frame (12) It is a rectangular groove made of steel plate. The cross section at both ends is larger than the middle, and it is trapezoidal. There are open grooves (10) on both sides of one end of the mold. One end of the mold (11) is fastened to the frame (12) with screws. (11) The other end of the blocking plate (9) welded two steel plates (4) (8), the steel plate (4) (8) has a square hole, one end of the screw (1) is a rectangular steel block (3), ( 3) There is a rectangular hole (5) inside. The square steel column (6) penetrates the square hole of the steel plate (4) (8) and the rectangular hole (5) at one end of the screw (1). The quartz load cell (7) is installed Between the rectangular hole (5) and the square steel column (6). The screw (1) passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com