Microbe method for preparing enamine and amine from valinemia

A technology of mycylamine and microorganisms, applied in the field of Stenotrophomonas maltophilia, can solve the problems of inapplicability of effective mycylamine and mass production of effective mycylamine, and weak decomposition ability of effective mycin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

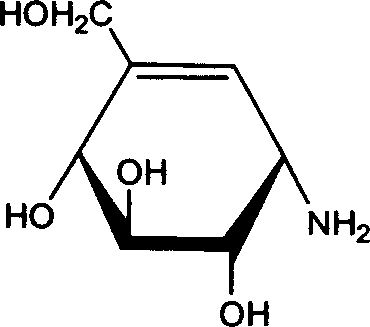

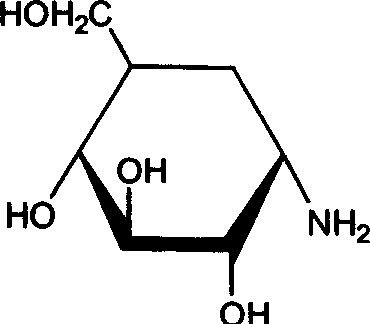

Image

Examples

Embodiment 1

[0055] Culture medium formula (weight / volume percentage, the same below): validamycin: 1.0%, (NH 4 ) 2 SO 4 : 1.0%, KCl: 0.5%, Na 2 HPO 4 12H 2 O: 1.0%, NaH 2 PO 4 2H 2 O: 0.1%, MgSO 4 : 0.01%, prepared with tap water, and adjusted the pH to 6.0 with HCl solution.

[0056] Take 100mL of the above-mentioned culture medium, divide it equally into two 250mL Erlenmeyer flasks, and sterilize. Inoculate the slant strain CCTCC No.M 204024, cultivate the bacteria, shake the table at a speed of 150r / min, and cultivate it at 28°C for 72 hours as a seed solution for later use.

[0057] Take 2L of the above culture medium, divide it into 20 500mL shake flasks, and sterilize. The seed liquid was inserted, the inoculum amount was 2% (v / v), and culture was carried out, the culture temperature was 20° C., the culture time was 160 h, and the shaker speed was 200 r / min.

[0058] Collect 1.8L of the above-mentioned fermentation broth, centrifuge to remove the bacteria, and the superna...

Embodiment 2

[0060] Medium formula Effectivemycin: 17.0%, (NH 4 ) 2 SO 4 : 8.0%, KCl: 0.5%, Na 2 HPO 4 12H 2 O: 1.0%, NaH 2 PO 4 2H 2 O: 0.1%, MgSO 4 : 0.01%, prepared with tap water, and adjusted the pH to 7.0 with NaOH solution.

[0061] Take 500mL of culture medium, evenly distribute it in five 500mL Erlenmeyer flasks, and sterilize. The slant strain CCTCC No.M 204024 was inserted and cultured at 28°C for 150 hours. The reaction was carried out under the conditions of stirring, ventilation and shaking, and the speed of the shaker was 200r / min.

[0062] 400 mL of the above-mentioned fermentation broth was collected, separated and purified, and the steps were the same as in Example 1 to obtain 0.56 g of available mycylamine and 0.85 g of available mycylamine.

Embodiment 3

[0064] Fermentation medium formula validamycin: 8.0%, (NH 4 ) 2 SO 4 : 6%, KCl: 0.1%, Na 2 HPO 4 12H 2 O: 1.0%, NaH 2 PO 4 2H 2 O: 0.16%, MgSO 4 : 0.02%, prepared with tap water, and adjusted the pH to 7.5 with NaOH solution.

[0065] Seed medium formula effectivemycin: 1.0%, (NH 4 ) 2 SO 4 : 1%, KCl: 0.5%, Na 2 HPO 4 12H 2 O: 1.0%, NaH 2 PO 4 2H 2 O: 0.1%, MgSO 4 : 0.5%, prepared with tap water, and adjusted the pH to 7.5 with NaOH solution.

[0066] Take 500mL seed culture medium, divide it into five 500mL Erlenmeyer flasks, and sterilize. Insert the slant strain CCTCC No.M 204024, cultivate the bacteria, shake the rotating speed of 200r / min, and cultivate in the shaking table at 30°C for 72 hours as the seed liquid, and set aside.

[0067] Take 8L of fermentation medium, divide it into 80 shake flasks of 500mL, and sterilize. Insert the seed solution, the inoculation amount is 5% (v / v), and cultivate, the cultivation temperature is 30°C, the cultivation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com