Tecnique for fabricating facing before pouring building facilities made from reinforced concrete

A technology of reinforced concrete and manufacturing technology, which is applied to the preparation of building components on site, construction, building construction, etc., and can solve problems such as complex construction process, water resistance on the surface, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

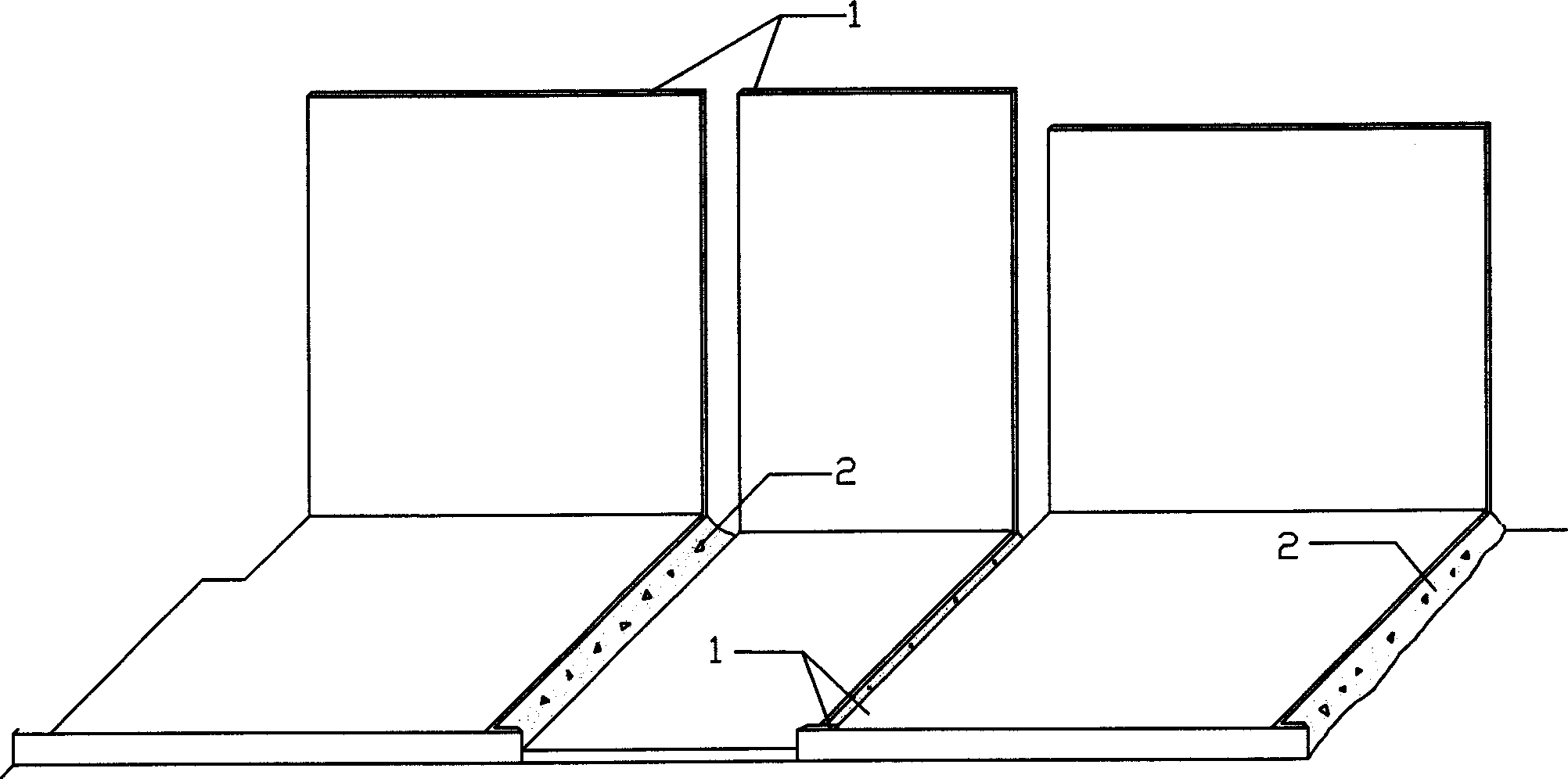

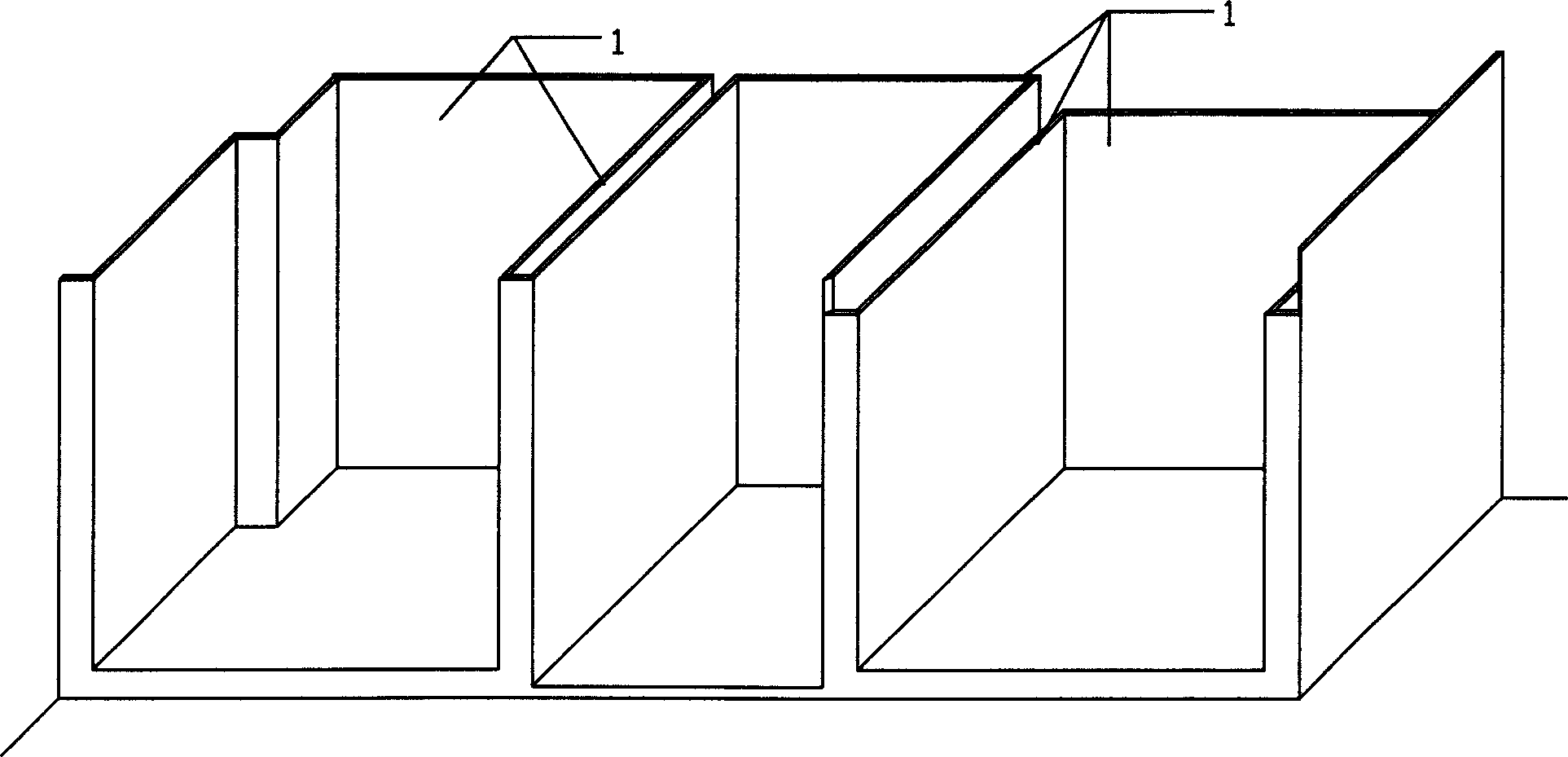

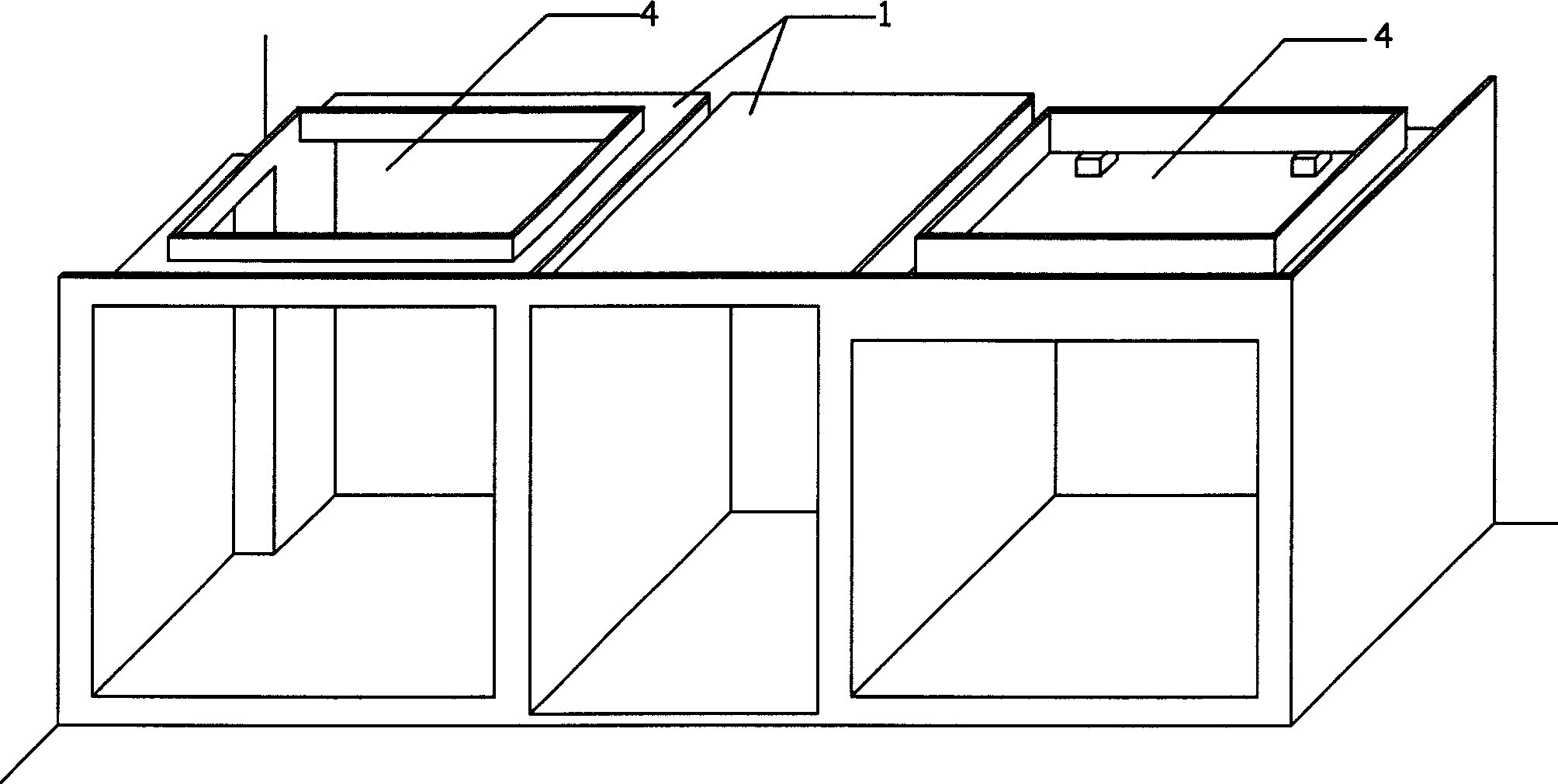

[0016] Hereinafter, the technical scheme of the present invention will be described in detail by taking the kitchen stove, chopping board, and sink as examples in conjunction with the drawings. The facing material 1 used in this embodiment is a stone plate or a glazed ceramic tile. First, the facing material 1 is firmly bonded to each other with a stone adhesive to construct the structural frame of the facility, and the adhesive used can be any one. A kind of adhesives for bonding stone and ceramic tiles, such as the Hercules brand marble glue produced by Shanghai Hercules Adhesive Co., Ltd. If you need a stronger bond, you can choose the Hercules brand AB glue produced by the company Of course, other adhesives can also be used, but it is better to bond the panels firmly.

[0017] First carry out the architectural design. You can design by yourself, or you can choose or refer to the building structure of the building standard atlas designed and drawn by the country and local, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com