Technique for plugging high penetrative water-yielding stratum in oil well by using superfine cement

An oil well ultra-fine cement and high-permeability technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of difficult control of water shutoff effect, low construction success rate, poor water shutoff effect, etc. , to achieve the effect of short construction period, low construction cost and good plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

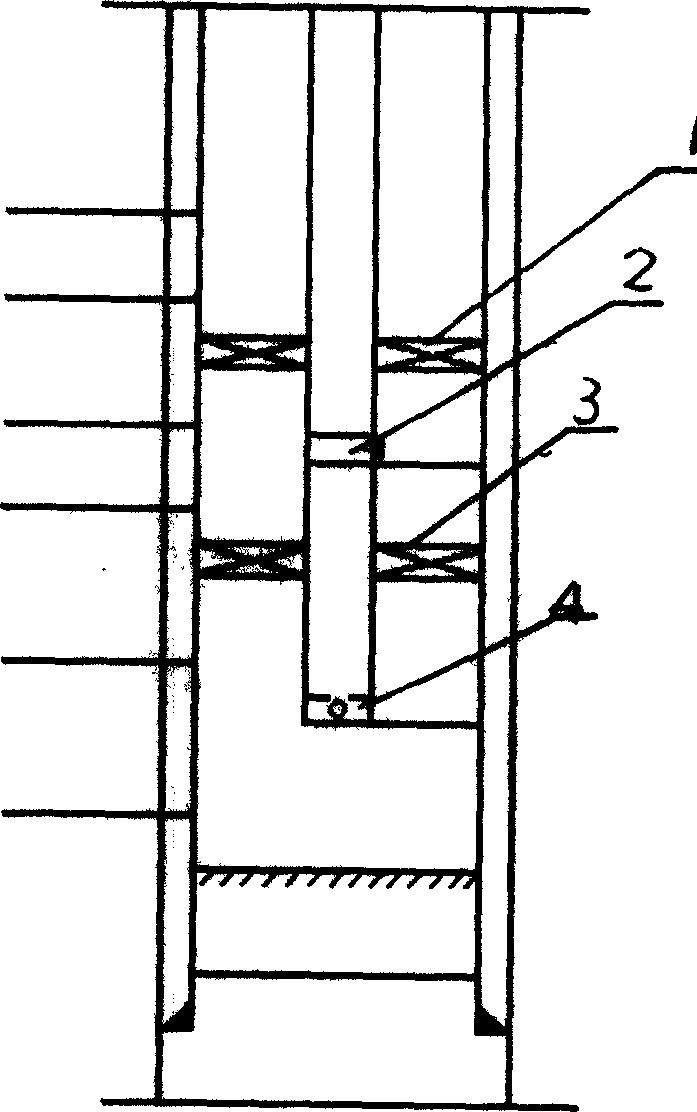

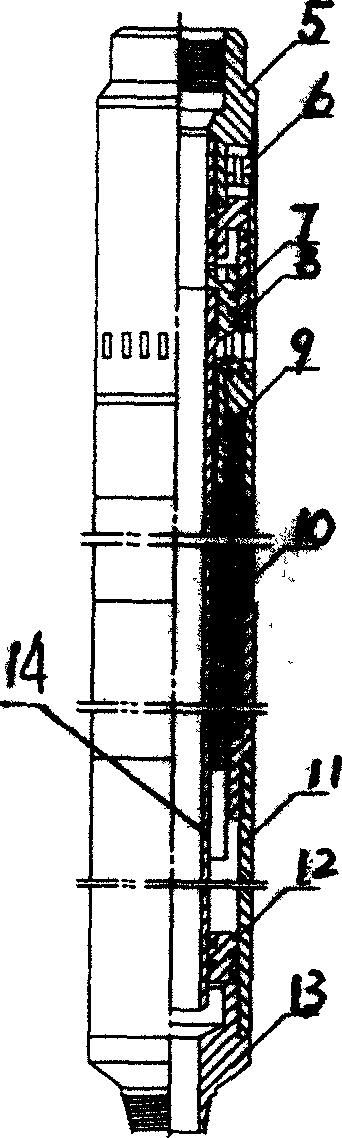

[0012] The utility model is provided by the following embodiments, which will be described below in conjunction with the accompanying drawings.

[0013] As shown in the figure, the pipe string of the water plugging construction process of the present invention is composed of upper and lower K341 hydraulic expansion packers 1, 3, a restrictor 2 arranged between them and a ball seat 4 at the lower end. Among them, K341 packers 1 and 3 (see figure 2 ) consists of an upper joint 5, an unblocking pin 6, a sealing rubber ring 7, a backwash check valve 8, a rubber cylinder gland 9, a rubber cylinder 10, a liquid cylinder 11, a piston 12, a lower joint 13 and a center pipe 14, and the center The upper and lower ends of the pipe 14 are respectively connected with the upper joint 5 and the lower joint 13 by threads; the outer middle part of the central pipe 14 is equipped with a rubber cartridge 10, and the upper and lower ends thereof are respectively provided with a rubber cartridge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com