Die changing method and device for stamping processing multiple die of sheet material

A stamping and multi-die technology is applied in the field of a die-changing method and a die-changing device for sheet-metal multi-die stamping, which can solve the problems of short service life, die-clamping error, and high cost, and achieve enhanced work stability and lower device costs. Cost and effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

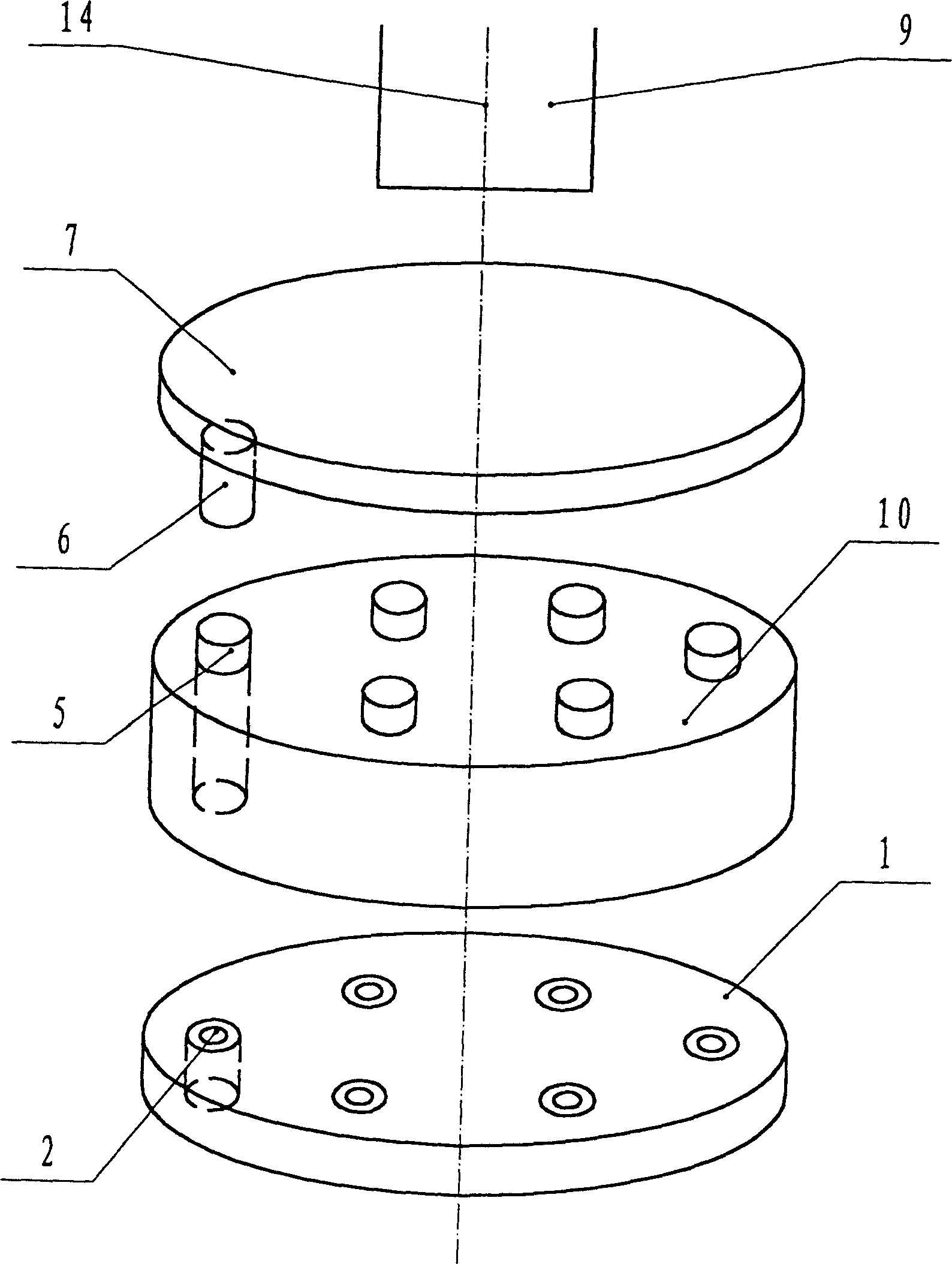

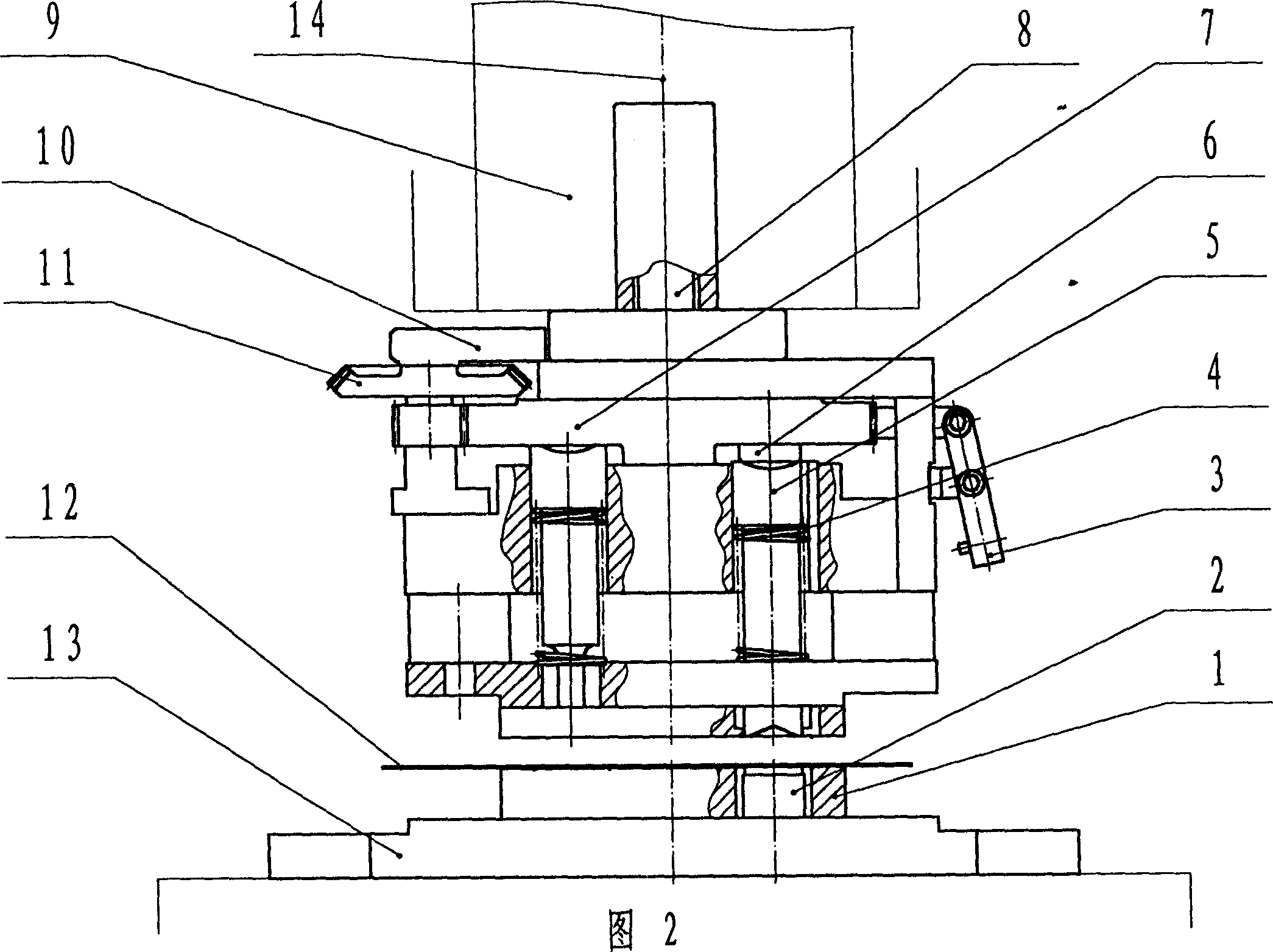

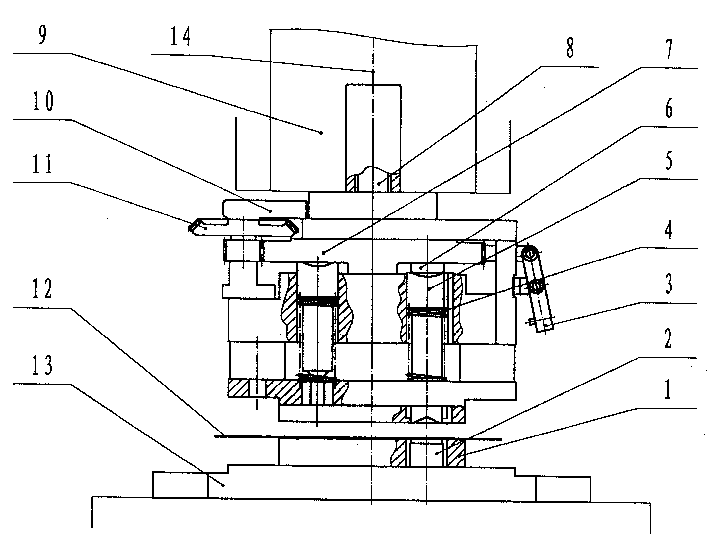

[0014] Specific embodiments of the present invention are described in further detail below in conjunction with accompanying drawing:

[0015] In the mold changing device for multi-die stamping of sheet metal shown in the figure, its lower mold frame 1 is fixed on the press frame 13 , and its upper mold frame 10 is fixed on the press hammer 9 . Taking the center line 14 of the hammer 9 of the press as the axis, the lower mold frame 1 is fixed with lower molds 2 of multiple pairs of molds arranged in the circumferential direction. On the upper die frame 10, the upper die 5 of the plurality of pairs of molds corresponding to each lower die 2 arrangement positions is installed, and each upper die 5 is supported by a stage clip 4, and can move vertically in the upper die frame 10. A rotary mold changer 7 is arranged above each upper mold 5 in the upper mold frame 10, and the rotary mold changer 7 is installed on the fixed shaft 8 overlapping with the center line 14 of the press ham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com