Driving device of full-automatic washing machine

A fully automatic washing machine and transmission technology, applied in the transmission and transmission fields of washing machines, can solve the problems of loss of power, complex structure of clutches and deceleration devices, low production efficiency, etc. deliver effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

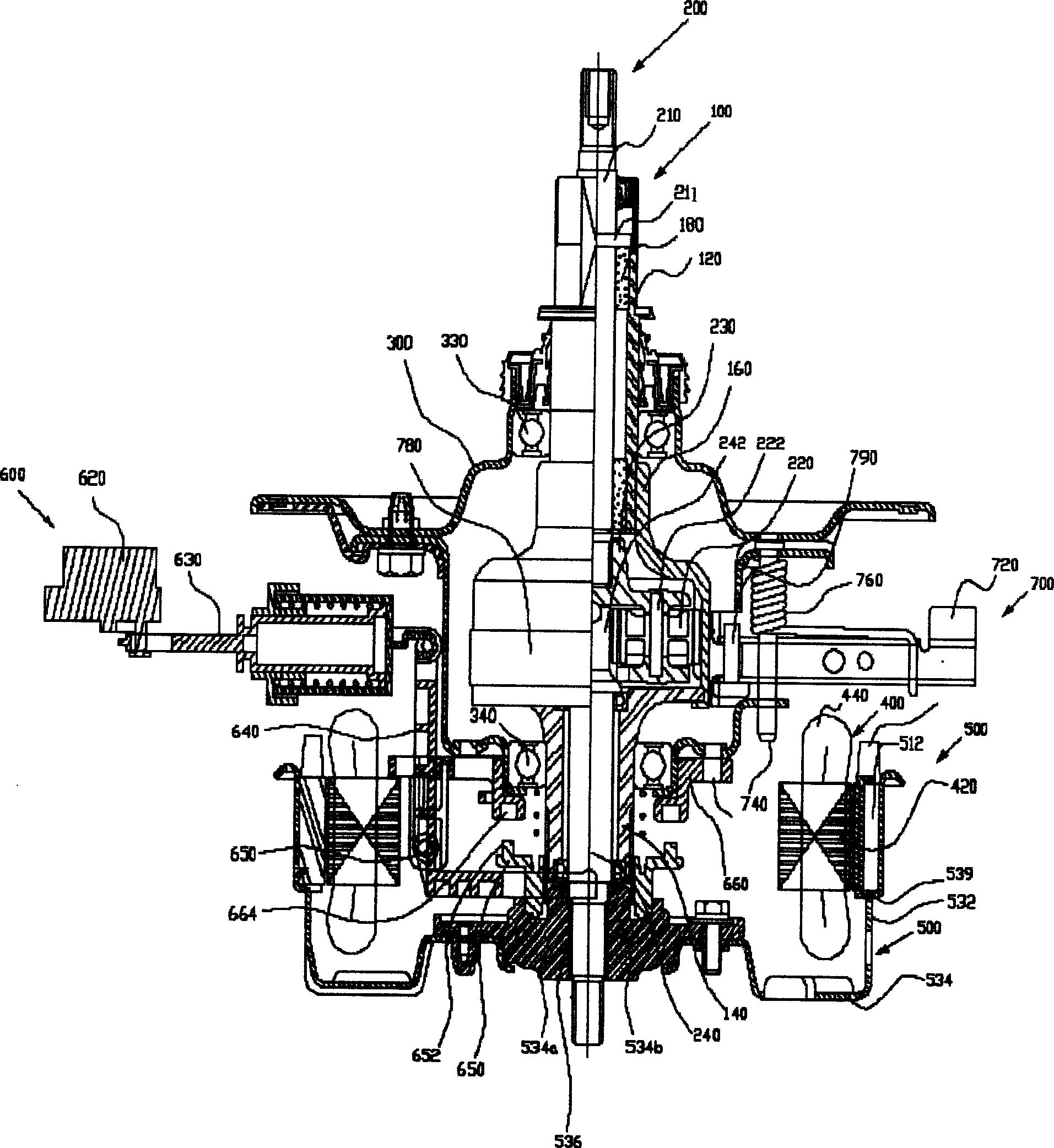

[0036] The transmission device of the fully automatic washing machine of the present invention will be further described in detail in connection with the accompanying drawings and specific embodiments:

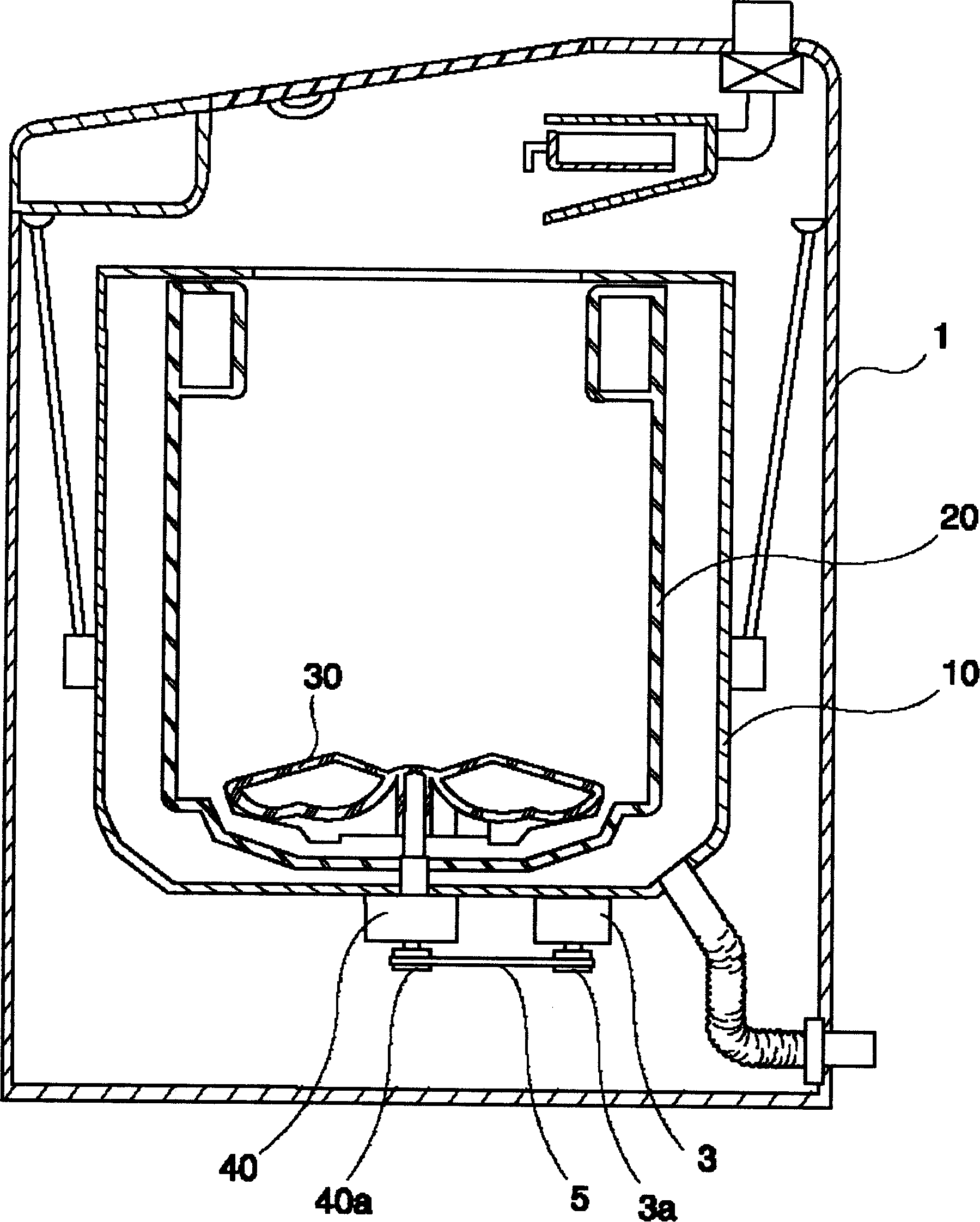

[0037] Such as image 3 As shown, the outer casing forms the shape of a washing machine, and there is an outer cylinder inside the outer casing for containing the washing water, and the outer cylinder holds the washing water. There is a laundry tub for both washing and dehydration inside the outer tub. Inside the washing tub, an upper washing shaft 210 is provided in a penetrating state, and an upper end of the upper washing shaft 210 has stirring blades for rotating the laundry in forward and reverse directions.

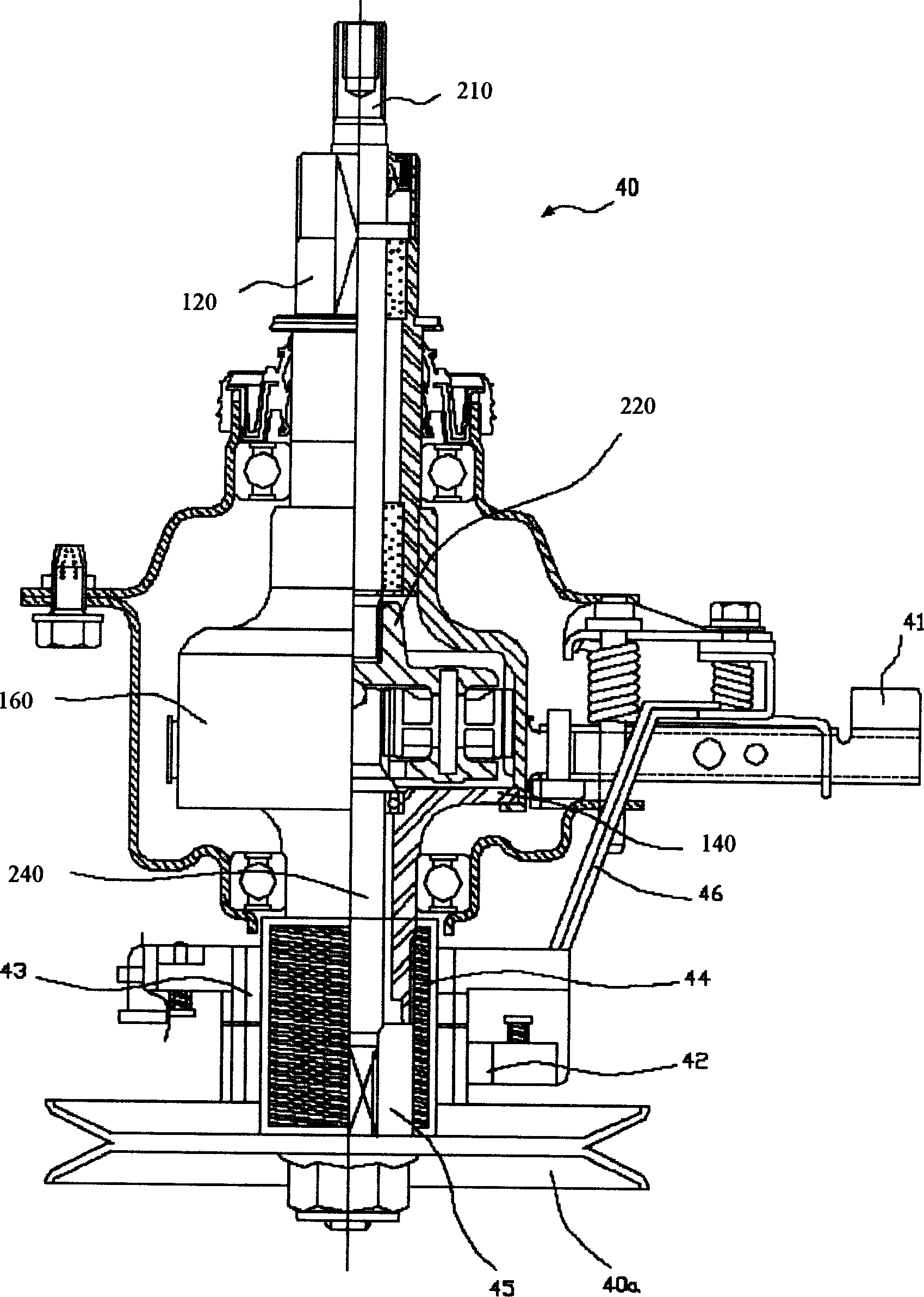

[0038] The dehydration shaft 100 for rotating the washing tub is directly connected to the washing tub. Moreover, the dehydration shaft 100 includes an upper dehydration shaft 120, a hub 160 and a lower dehydration shaft 140. The upper dehydration shaft 120 rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com