Process for producing fermented alcoholic drink

A technology for fermenting alcohol and a manufacturing method, which can be applied to beer fermentation methods, beer brewing, malt preparation and other directions, and can solve problems such as poor filterability and reduced yield of extracts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

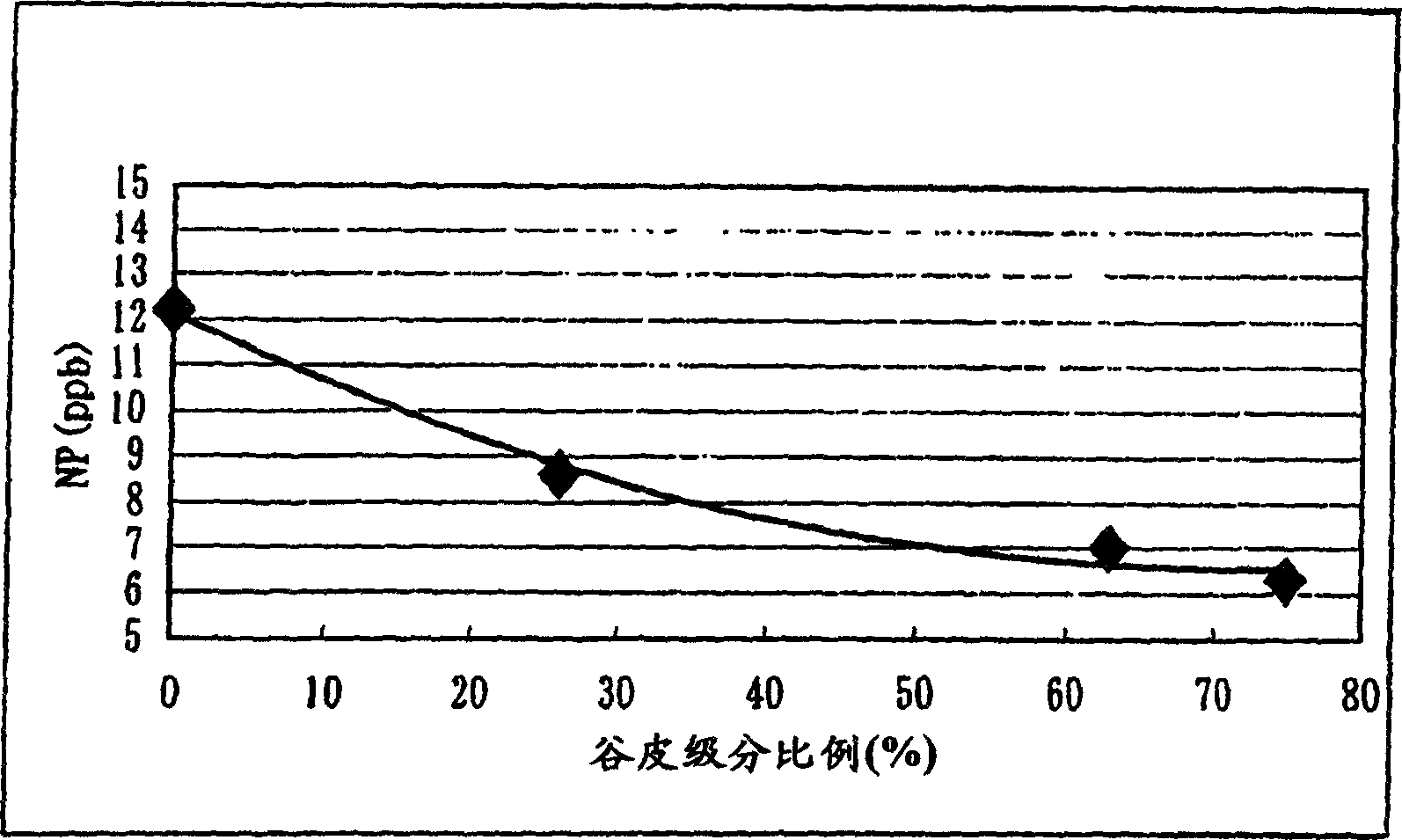

[0029] Example 1 Malt pulverization degree and extract content of feeding wort (filtered wort), NP (trans-2-nonenal potential)

[0030] [Measurement of NP]

[0031] 1 / 5 or 1 / 10 amount of wort was added to 0.2M acetate buffer (pH 4), sealed and boiled for 2 hours. After cooling to room temperature, according to the method of Verhagen et al. (J. Chromatgr., 393 (1987) 85-96), solid phase extraction of trans-2-nonenal was carried out with Sep-Pak C18 column with dansyl hydrazide. After derivatization, analysis was performed by HPLC using the column transfer method. Using HP 1100 manufactured by Hewlett Packard, with column 1 (for extraction) 100 × 4.6 mm, YMC-Pack, ODS-AM, flow rate 1.0 ml / min; column 2 (for separation) 250 × 4.6 mm, YMC-Pack , ODS-AM, flow rate 0.85ml / min for analysis, and the trans-2-nonenal measured in each wort unit is expressed in ppb, which is NP.

[0032] [Sugar content and NP of filtered wort when changing the degree of malt grinding]

[0033] As show...

Embodiment 2

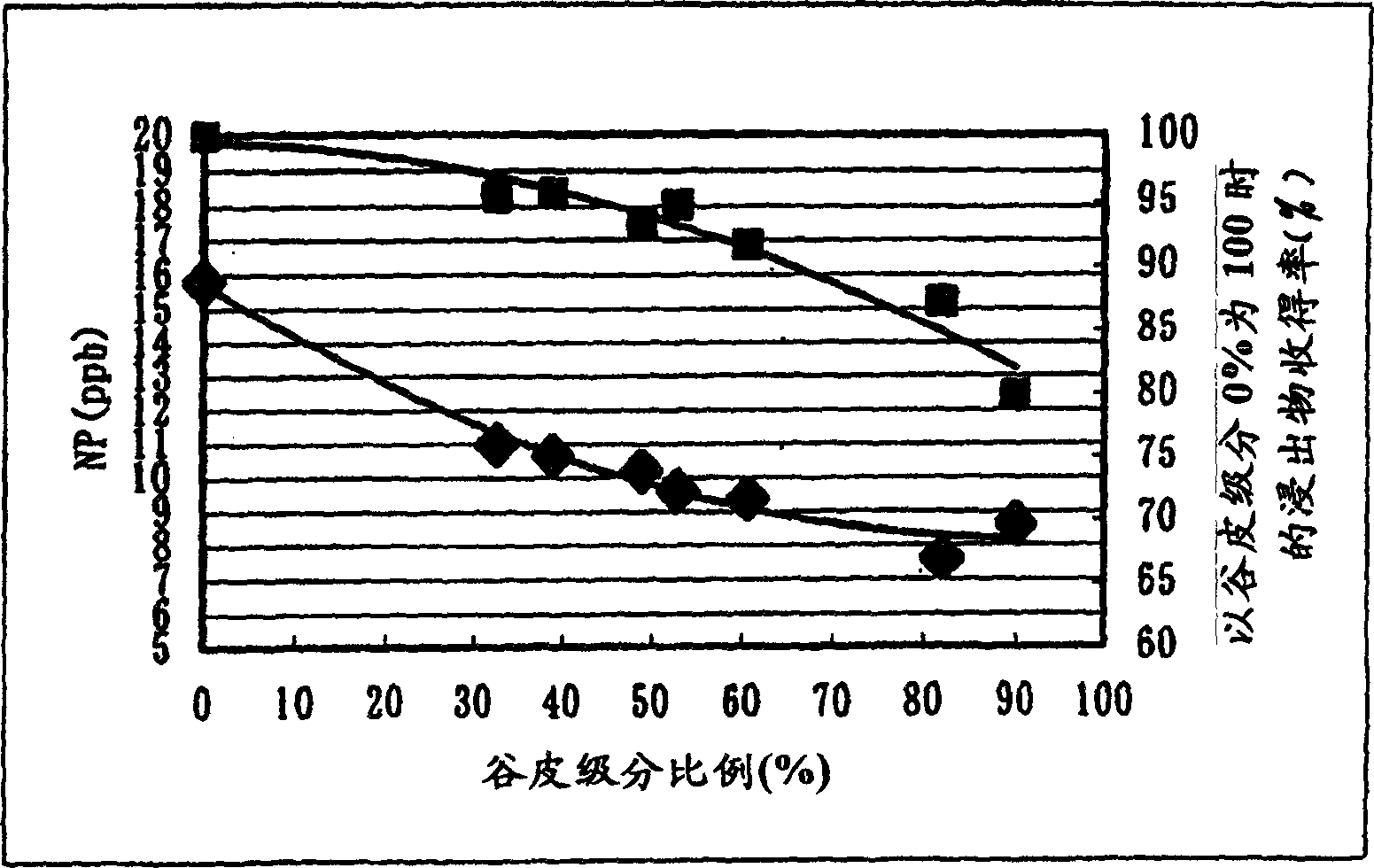

[0038] Example 2 The degree of grinding of barley and the extract content, NP of feeding wort (filtered wort)

Embodiment 3

[0047] Example 3 Production of fermented beverages from feed wort with varying degrees of malt pulverization

[0048] Saccharified mash is prepared from malt (more than 70%), auxiliary materials (rice, corn, starch) and hot water according to a conventional method, filtered to obtain filtered wort, hops are added to the filtered wort, boiled, and the coagulum is removed after boiling , cooled, adjusted the wort concentration to 11°P, then added yeast to ferment, and stored at 0°C after fermentation to obtain beer. As for the malt raw material, the malt with coarse grinding degree was compared with normal malt. The pulverization degree of malt is shown in Table 7, and the evaluation of fermented beer is shown in Table 8. In Table 8, the degree of the aged smell was classified into a scale of 0 (none) to 3 (very strong), and the evaluation was carried out by 5 professionals, and the average value was taken. The strength of the aged smell of the product in the storage test (sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com