Automatic detection separator for quartz crystal resonator

A quartz crystal and automatic detection technology, which is applied in sorting and other directions, can solve the problems of low detection accuracy, inconvenient maintenance, and high cost, and achieve the effects of high detection accuracy, easy maintenance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described through the embodiments below with reference to the accompanying drawings.

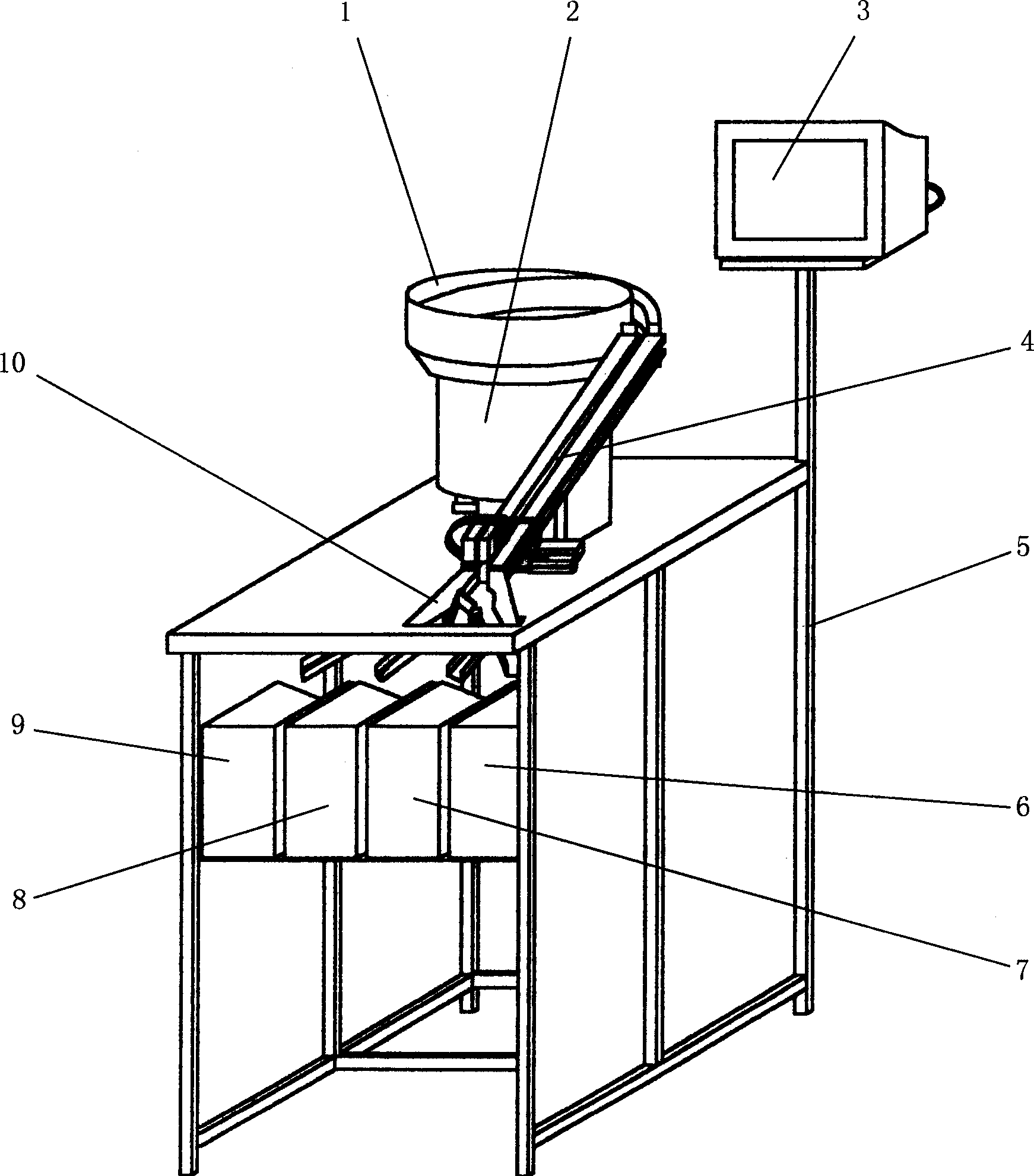

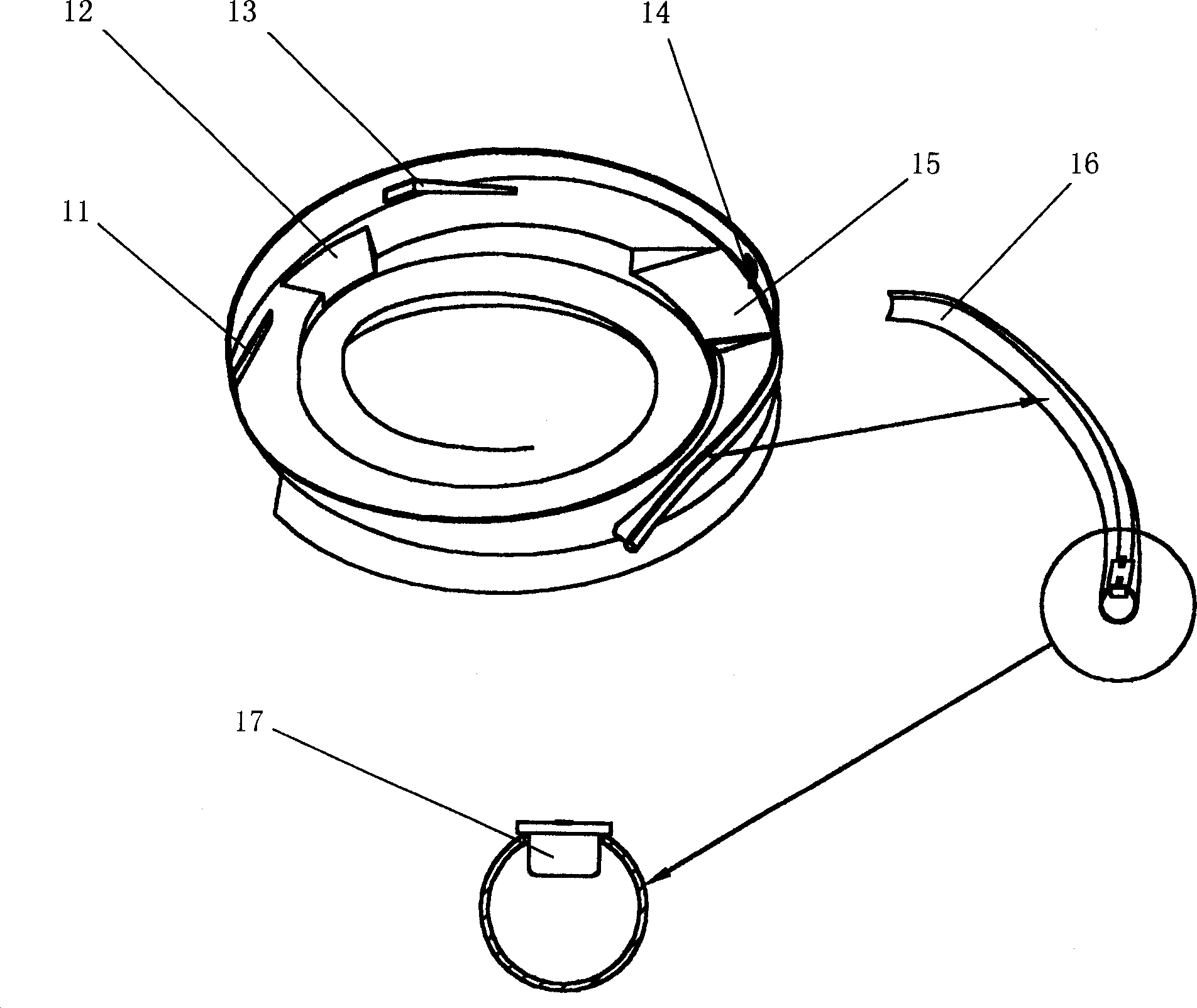

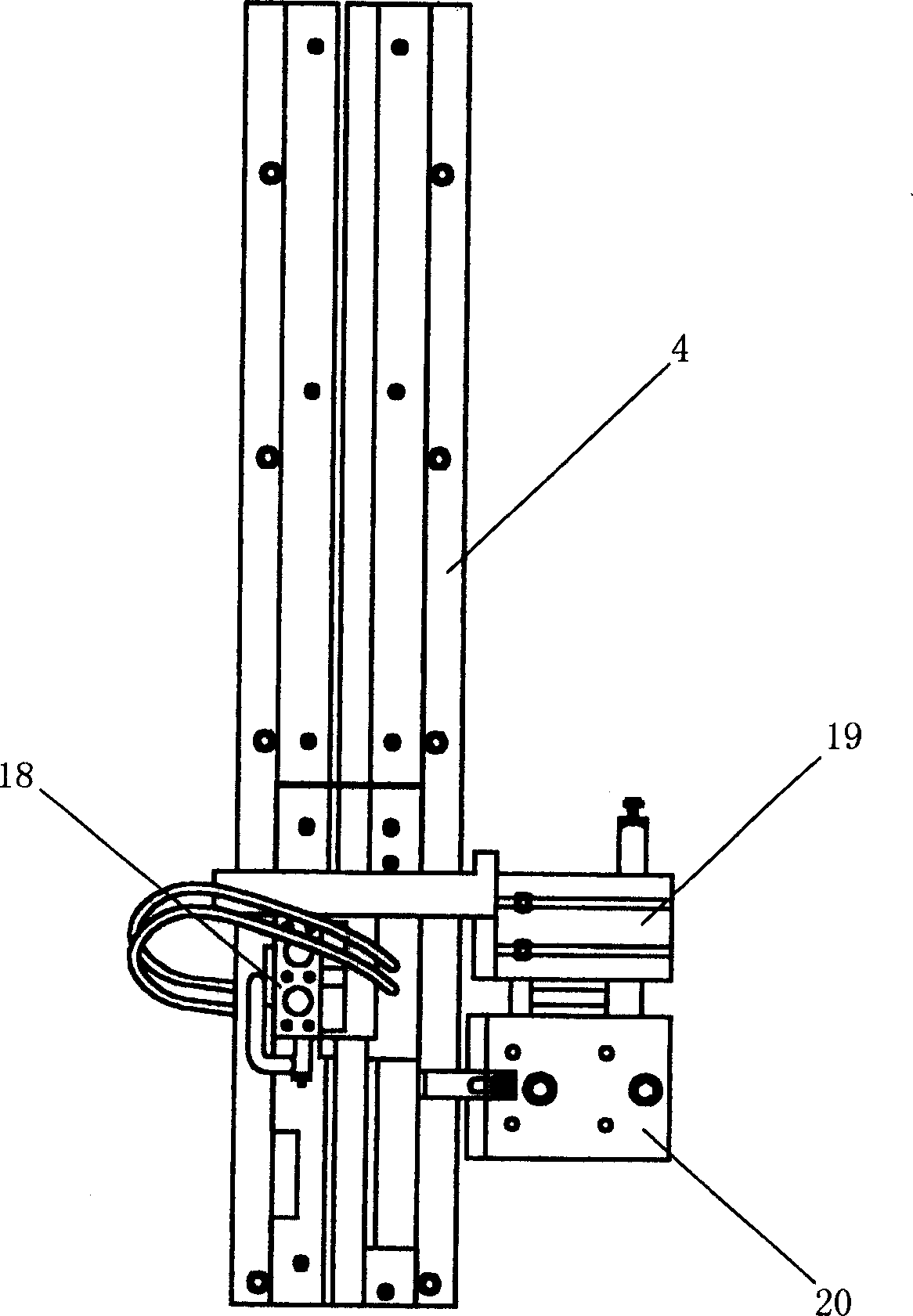

[0015] Refer to attached figure 1 to attach Figure 6 An automatic detection and sorting machine for quartz crystal resonators includes three parts: a test system, a drive control system and a sorting system. The test system includes a computer 3, a 250B network analyzer 23, and test software. Die conversion card, solenoid valve, test head cylinder 18, single-action discharging cylinder 19, material retaining cylinder 20, sorting system includes rack 5, automatic feeding vibrating plate 1, container 2, slideway 4, four-speed automatic material sorting Slideway 10 and four material storage boxes. Among them, the container 2 is fixed on the top of the frame 5, the automatic feeding vibrating plate 1 is arranged on the top of the container 2, and the inner side of the automatic feeding vibrating plate 1 is sequentially provided with a guide baffle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com