Surface antibiotic, wearable stainless steel products and its production method

A surface antibacterial, stainless steel technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of the antibacterial effect is not durable, the antibacterial has no practical significance, and the wear resistance is poor, and achieves durable wear resistance. , The production is simple and convenient, the effect of good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

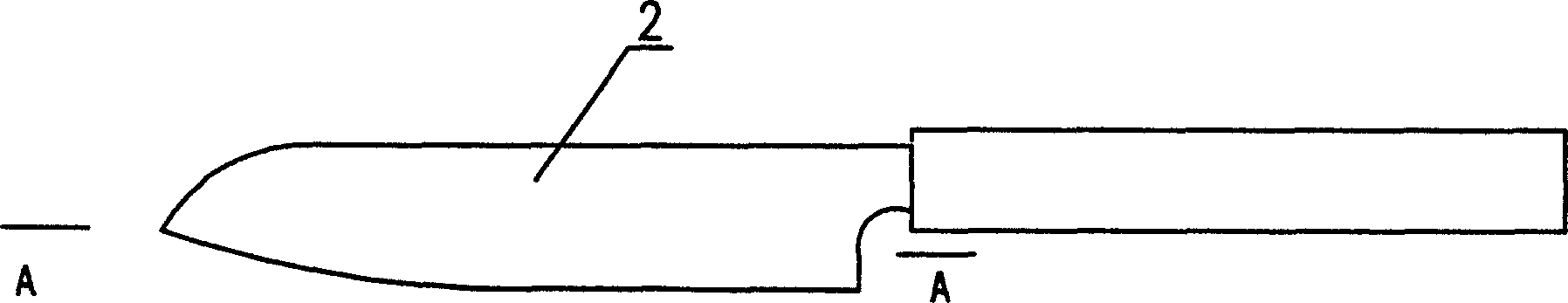

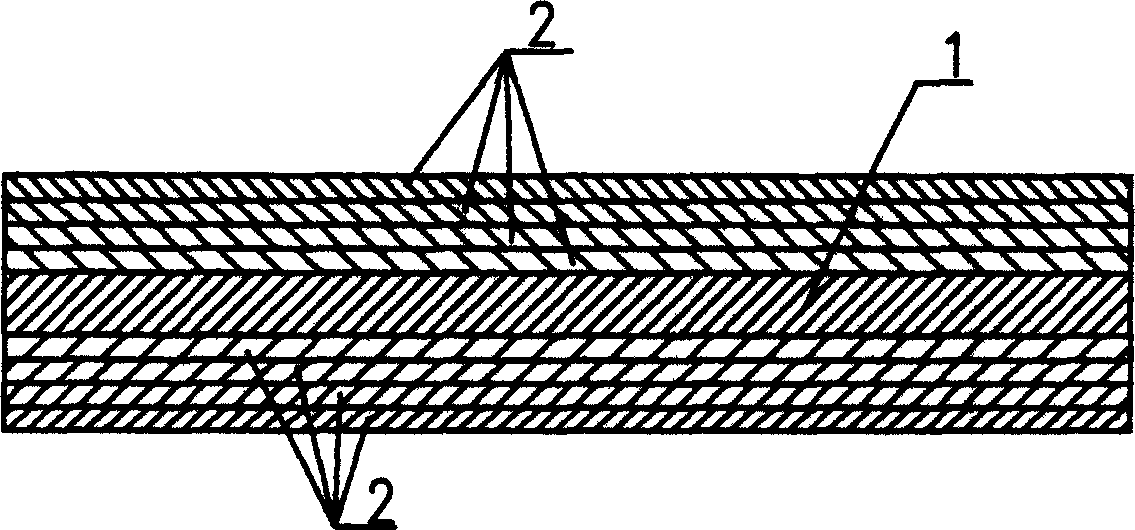

[0019] The structural schematic diagram of the surface antibacterial and wear-resistant stainless steel product of the present invention is as follows: figure 1 , 2 As shown, a stainless steel base material (1) and several TiAgN coating layers (2) are included, and the TiN and TiAgN coating layers (2) are plated on the outside of the stainless steel base material (1).

[0020] The above-mentioned several TiN and TiAgN coating layers (2) may be one layer or more than one layer. In this embodiment, the TiN and TiAgN coating layers (2) may be four layers.

[0021] The silver and titanium components contained in the above-mentioned TiN and TiAgN coating layers (2) change in steps, that is, the inner coating layer contains low silver content and high titanium content, and the outer coating layer contains high silver content and low titanium content.

[0022] The silver content of the innermost coating layer may be 0-0.3%, and the silver content of the outermost coating layer may ...

Embodiment 2

[0028] The structure of the surface antibacterial and wear-resistant stainless steel product of the present invention is the same as that of Example 1, except that the TiN and TiAgN coating layers (2) can be 5 layers. The silver content of the innermost coating layer may be 0.15%, and the silver content of the outermost coating layer may be 15%. The thickness of the innermost coating layer may be 0.05um, and the thickness of the outermost coating layer may be 5um.

[0029] The preparation method of the surface antibacterial and wear-resistant stainless steel product of the present invention adopts the magnetron sputtering method. Filling with nitrogen can generate TiAgN and TiN.

[0030] Due to the different sputtering yields of different elements, the sputtering threshold is higher for titanium and lower for silver. Therefore, multiple titanium palladiums are arranged in the sputtering furnace cavity to increase the sputtering yield of titanium. In addition, the sputtering...

Embodiment 3

[0033] The structure of the surface antibacterial and wear-resistant stainless steel product of the present invention is the same as that of Example 1, except that the TiN and TiAgN coating layers (2) can be 6 layers. The silver content of the innermost coating layer may be 0.3%, and the silver content of the outermost coating layer may be 30%. The thickness of the innermost coating layer may be 0.1um, and the thickness of the outermost coating layer may be 10um.

[0034] The preparation method of the surface antibacterial and wear-resistant stainless steel product of the present invention adopts the magnetron sputtering method. Filling the shield with nitrogen can generate TiAgN, TiN, AgN, and Ag.

[0035] In this embodiment, 6 pieces of metallic silver with different areas are mounted on 6 pieces of titanium targets, 6 pieces of titanium targets are placed in the sputtering furnace cavity, and 6 pieces of palladium material are sputtered respectively for the 6 coating layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap