Separately controlled printed circuit board

A technology for printed circuit boards and control circuits, which is applied in the directions of printed circuit components, structural connections of printed circuits, instruments, etc., and can solve problems such as large area and breakage of flexible circuit boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

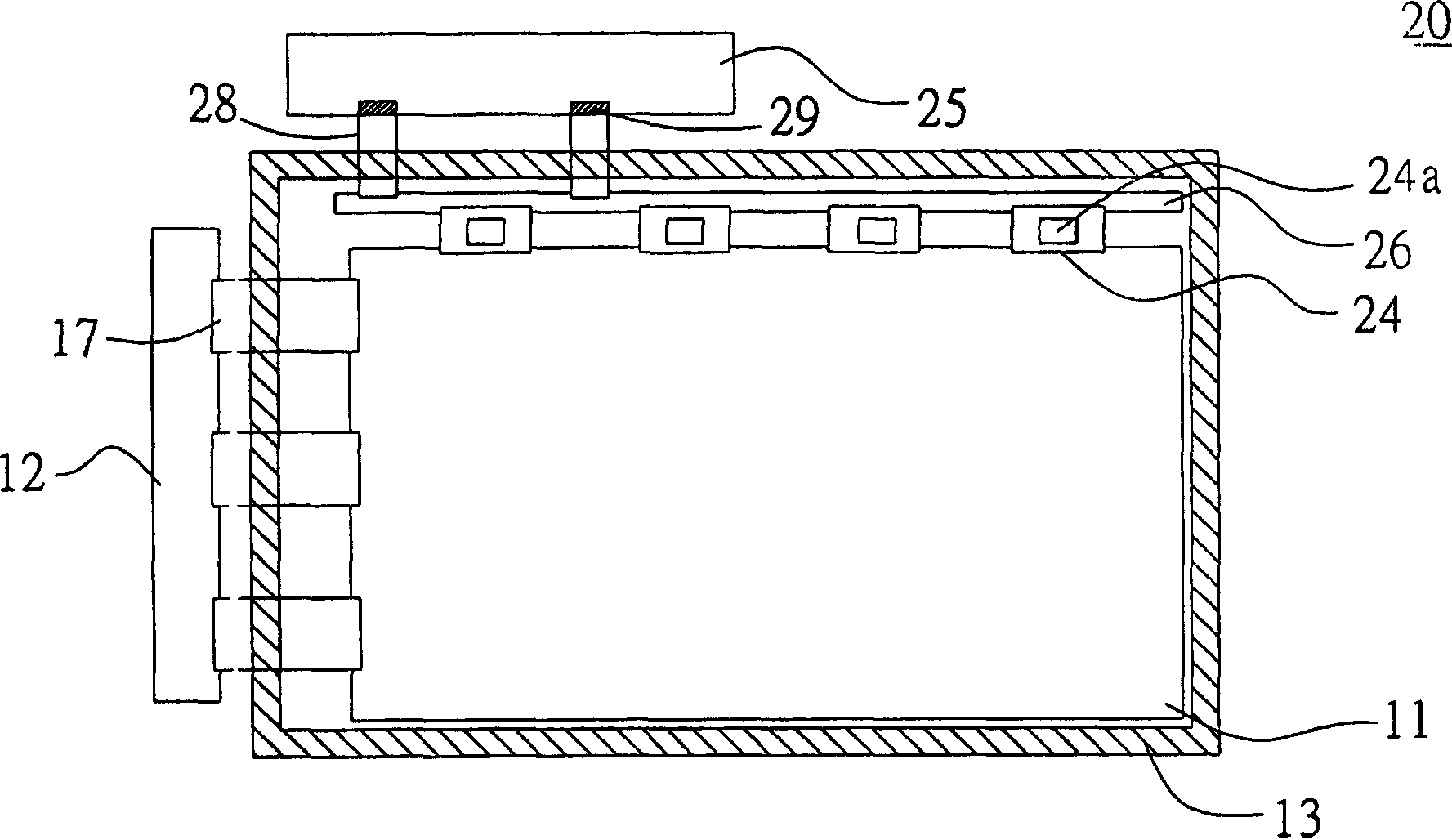

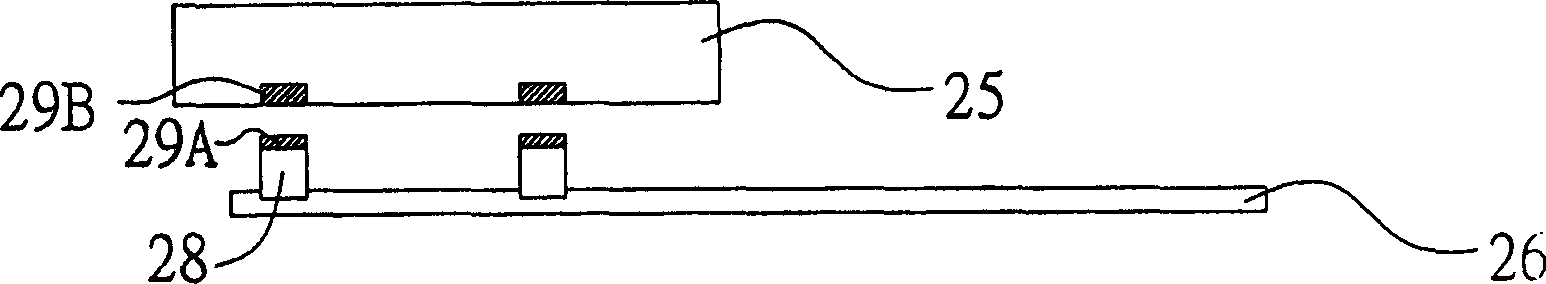

no. 1 example

[0035] Please refer to Figure 2A , which is a partial schematic view of the display according to the first embodiment of the present invention. The liquid crystal display 20 includes a separate control printed circuit board composed of a main source circuit board 25 and an auxiliary source circuit board 26, a gate control printed circuit board 12 and a plurality of flexible circuits connected thereto board (FPC) 17 , a display panel 11 and a frame 13 . A control circuit is configured on the main source circuit board 25 for outputting control signals. The auxiliary source circuit board 26 is electrically connected to the main source circuit board 25 via a plurality of flexible circuit boards 28 . The auxiliary source circuit board 26 is electrically connected to the display panel 11 by at least one TCP 24 , and the circuit on the auxiliary circuit board 26 can transmit or amplify the control signal of the main circuit board 25 to the display panel 11 . Each TCP 24 is configu...

no. 2 example

[0041] The separated control printed circuit board of the present invention can also be applied to the grid control printed circuit board. The grid control printed circuit board is separated into a main grid circuit board and an auxiliary grid circuit board. Please refer to FIG. 3A , which is a partial schematic diagram of a display according to a second embodiment of the present invention. The liquid crystal display 30 includes a separate grid control printed circuit board and a source control printed circuit board composed of a main grid circuit board (Main Gate PCB) 32 and an auxiliary grid circuit board (Auxiliary Gate PCB) 33 (Source PCB) 15 and the TCP 14 connected thereto, a display panel 11 and an outer frame 13 .

[0042] The auxiliary grid circuit board 33 is electrically connected to the main grid circuit board 32 through a plurality of flexible circuit boards 38 , and the auxiliary grid circuit board 33 is also electrically connected to the display panel 11 throug...

no. 3 example

[0046] According to the third embodiment of the present invention, the separate control printed circuit board can also be applied to the source control printed circuit board and the gate control printed circuit board at the same time. Please refer to FIG. 4 , which is a partial schematic diagram of a display according to a third embodiment of the present invention. The liquid crystal display device 40 of the third embodiment of the present invention includes a separate source control printed circuit board composed of a main source circuit board 45 and an auxiliary source circuit board 46, and a main gate circuit board 42 and an auxiliary source circuit board 46. A separate grid control printed circuit board composed of an auxiliary grid circuit board 43, a flexible circuit board (FPC) 47 connected to the auxiliary grid circuit board 43, a TCP44 connected to the auxiliary source circuit board 46, a The display panel 11 and an outer frame 13 .

[0047] The main source circuit b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com