Reversing ratchet wrench

A ratchet wrench and wrench handle technology, applied in the direction of wrenches, manufacturing tools, wrenches, etc., can solve the problems of affecting the efficiency of the clamping drive, inaccurate commutation, and reduced efficiency, so as to improve the clamping effect and stabilize the bonding relationship. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] About technology, means and effect thereof that the present invention adopts, preferred embodiment is cited hereby and is described in detail as follows in conjunction with accompanying drawing;

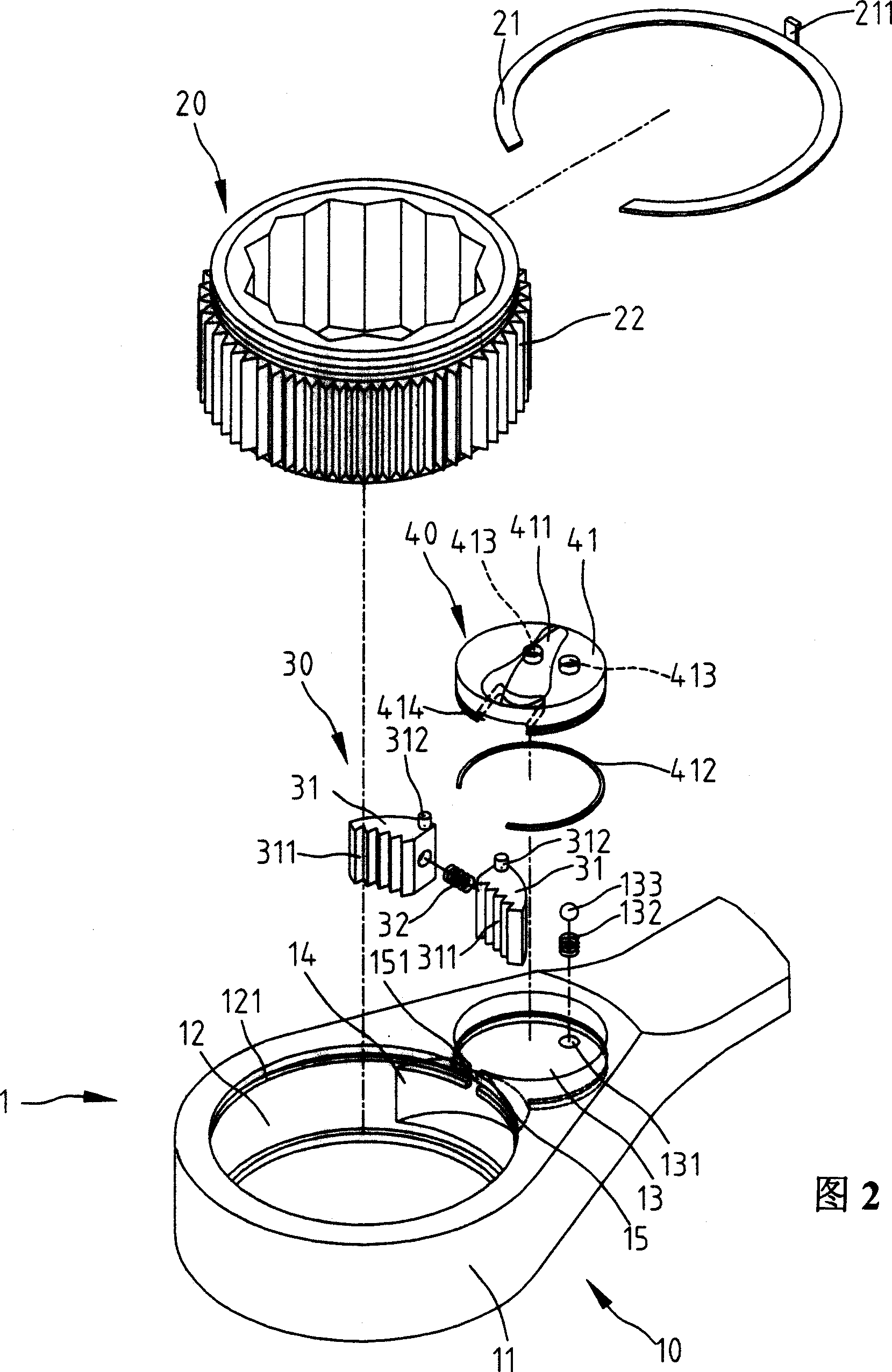

[0036] Please see first Figure 1 ~ Figure 4 Shown is the structure of an embodiment selected by the present invention, which is for illustration only, and the present invention is not limited by this structure.

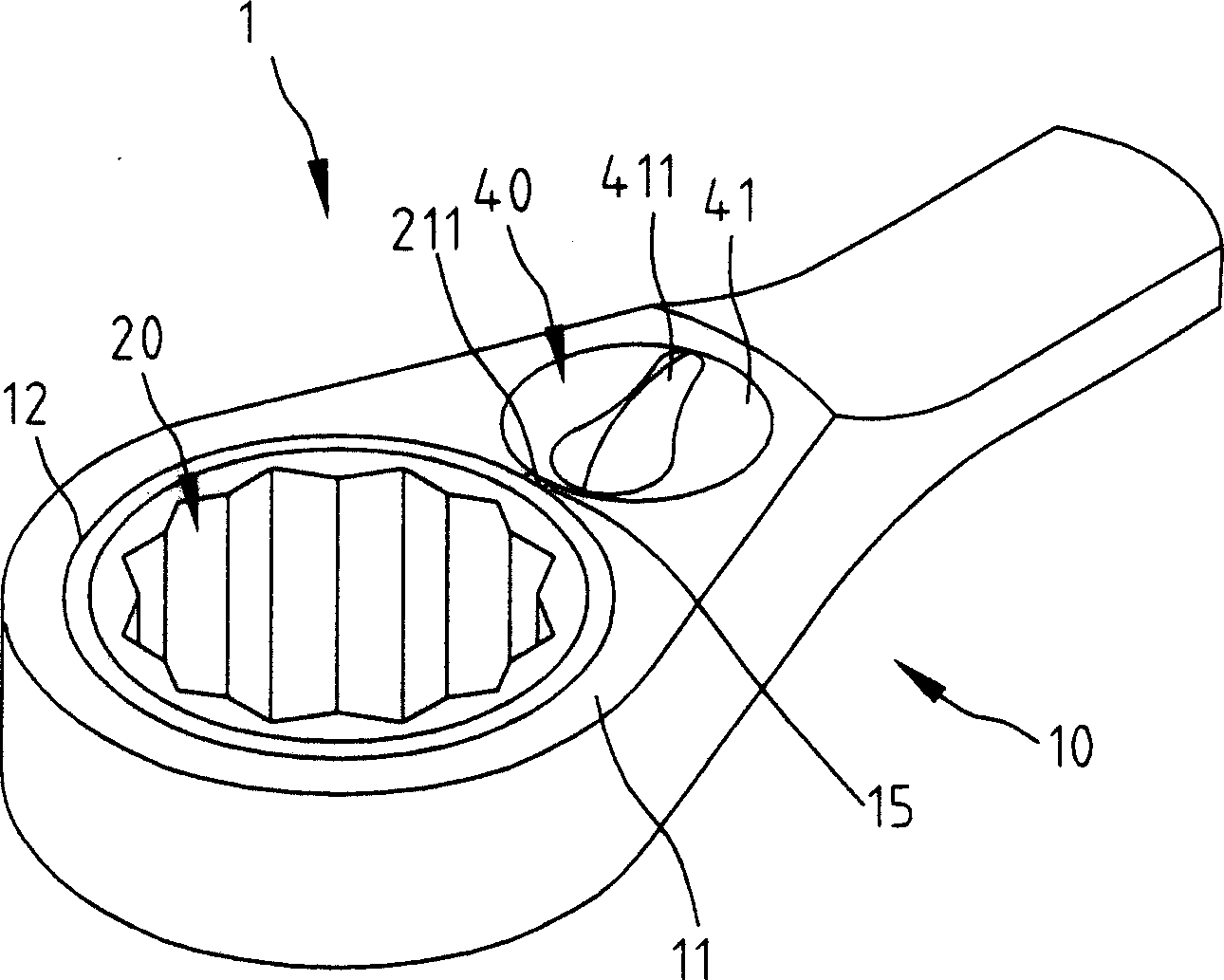

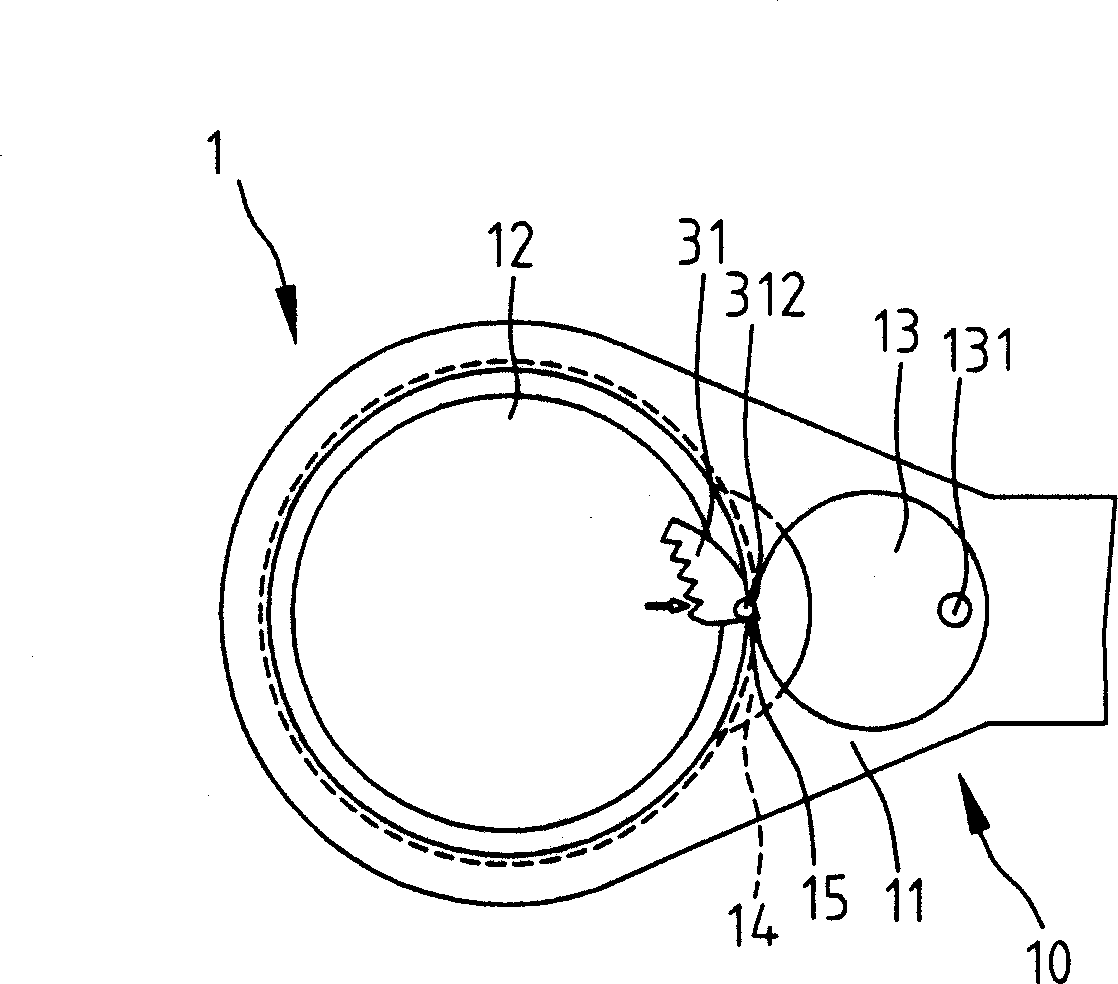

[0037] refer to figure 1 The ratchet wrench 1 of the present invention includes a wrench handle portion 10, and one end of the wrench handle portion 10 is provided with a driving portion 11, and the driving portion 11 passes through a coupling hole 12 for a driving device 20 to be fastened and combined. The driving part 11 is further provided with a direction control device 40 at a predetermined position adjacent to the coupling hole 12 . By adjusting the deflection of the direction control device 40 , the direction of rotation of the driving device 20 relative to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com