Injection stretch blow molding method of a cylindrical narrow mouth container and a container

An injection stretch blow molding, cylindrical technology, applied in the field of containers, can solve the problems of cracking, deepening, lack of strength against impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

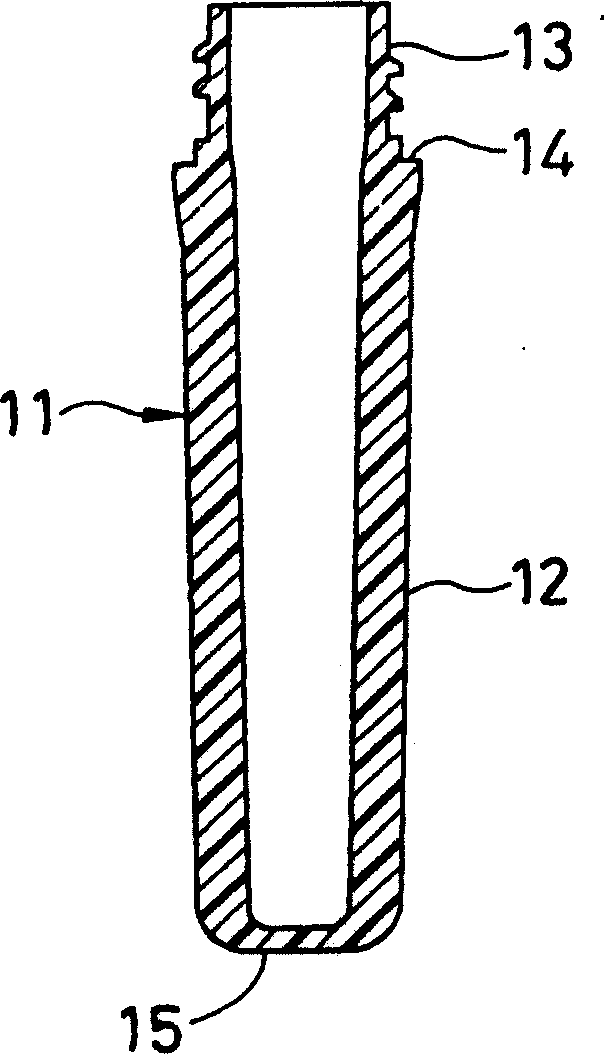

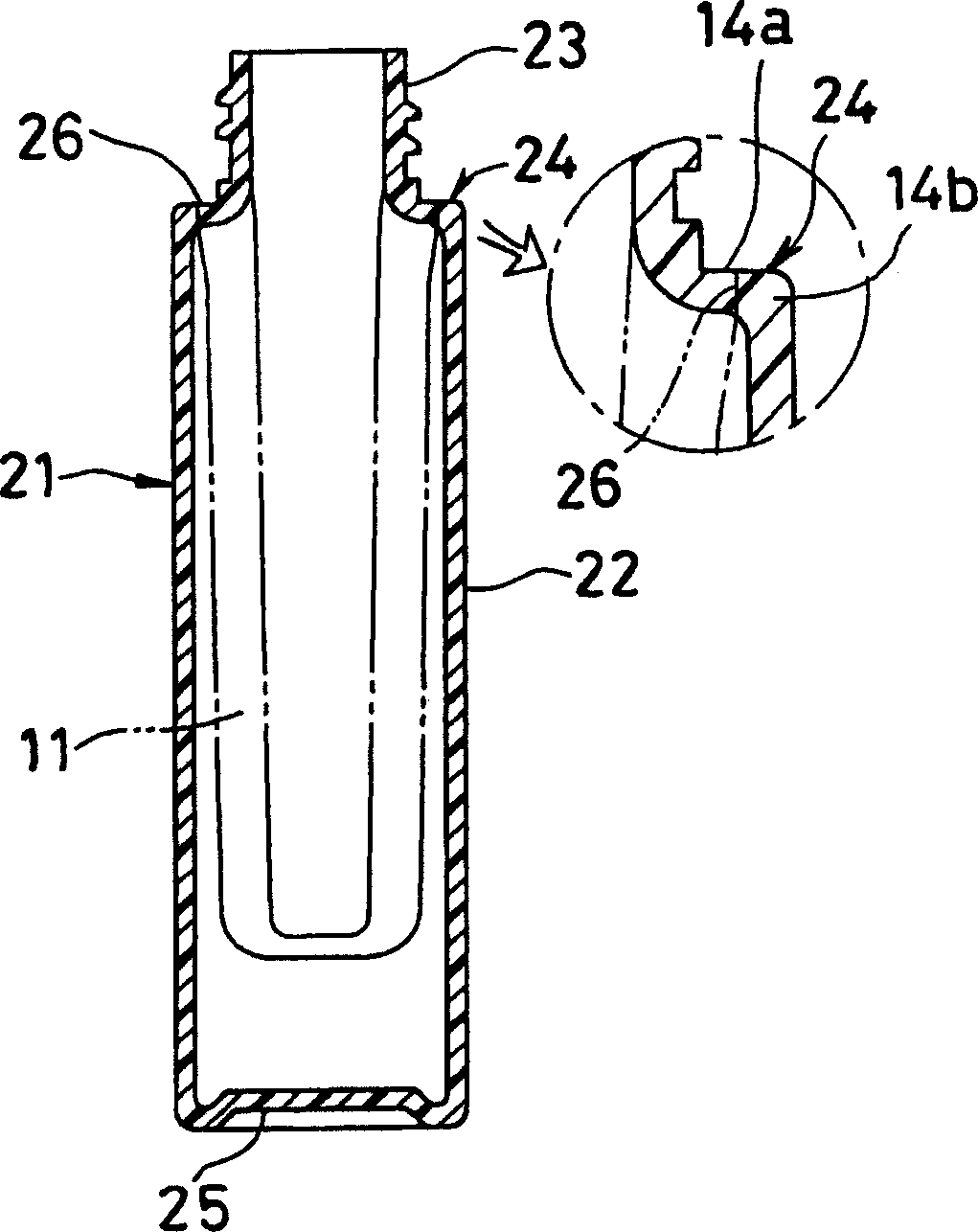

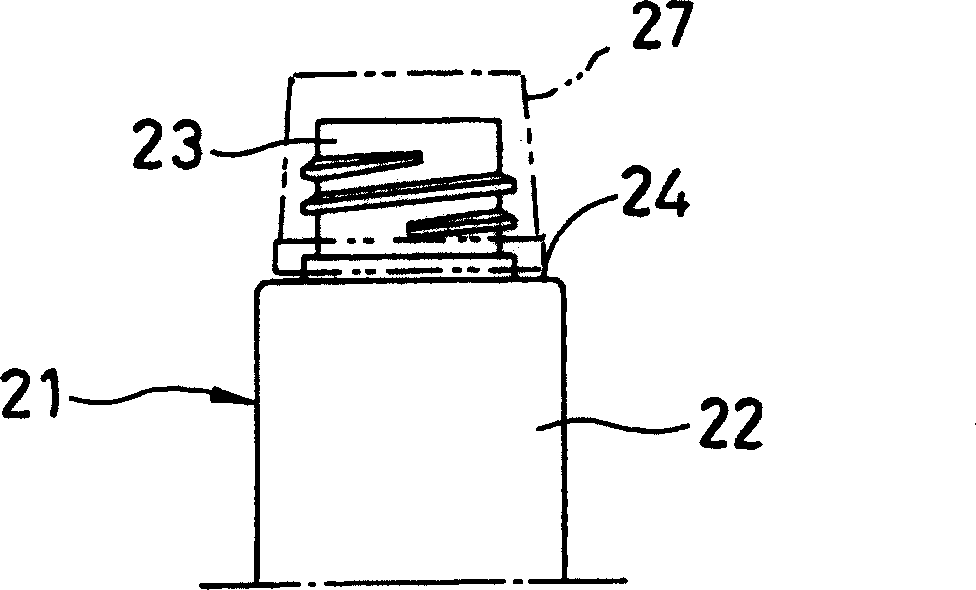

[0025] Figure 1 to Figure 4 An example of a stretch blow molding method according to the invention is shown.

[0026] According to the present invention, if image 3 As shown, the injection cavity mold 31 and the neck mold 33 are closed, an injection core 34 is inserted into the cavity 32 through the neck mold 33, and molten metal is injected into the cavity 32 from the nozzle 36 at the bottom of the cavity 32. Resin (such as PET) is filled with, and cavity 32 forms the cylindrical body part 12 of a preform 11 and the bottom 15, and neck mold 33 forms a neck 13 that has external thread, and from neck mold 33 and injection Starting from the closed face of the cavity mold 31 , the body part 12 has a larger outer diameter and thicker walls than the neck 13 .

[0027] The stepped portion 14 formed between the main body portion 12 and the neck portion 13 has an outer diameter slightly larger than the main body portion 12 of the preform and slightly smaller than the main body por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com