Method for the manufacture of a piston

A manufacturing method, piston technology, applied in the direction of pistons, shock absorbers, transportation and packaging, etc., can solve the problems of small indentation, difficult adjustment of vibration damping force, etc., to reduce the indentation, diameter and/or thickness Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

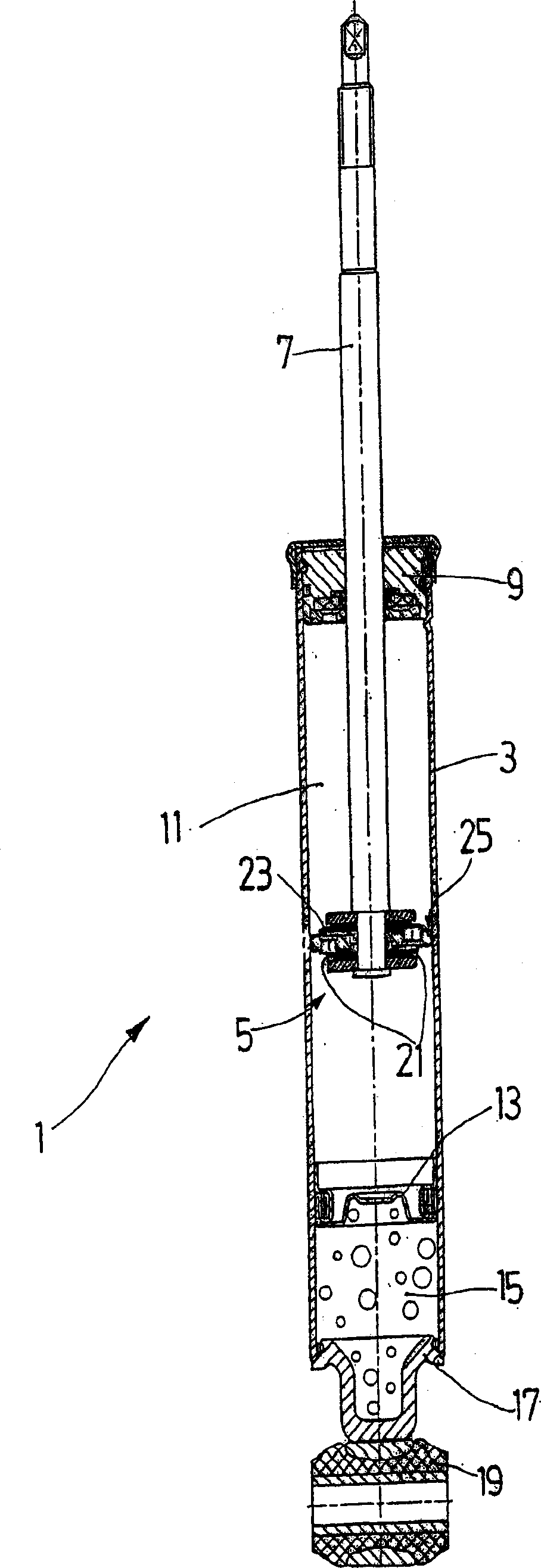

[0016] FIG. 1 shows an example of a piston-cylinder unit 1 in the form of a monotube shock absorber. In principle, the invention can also be used in other or piston-cylinder units.

[0017] A monotube shock absorber 1 essentially comprises a pressure tube 3 in which a piston 5 is mounted axially displaceable on a piston rod 7 . On the outlet side of the piston rod 7, a piston rod guide 9 closes a working chamber 11 filled with a damping medium, which is separated by a separating plug 13 from a gas chamber 15 which has a hole 19 at the end. Bottom plate 17.

[0018] When the piston rod is moved, damping medium flows through a damping valve 21 in the piston 5 , which is formed by a spool 23 . A piston ring 25 covering the outer circumference of the piston 5 prevents the flow of damping medium around the piston and takes over the task of guiding the piston in a friction-reduced manner.

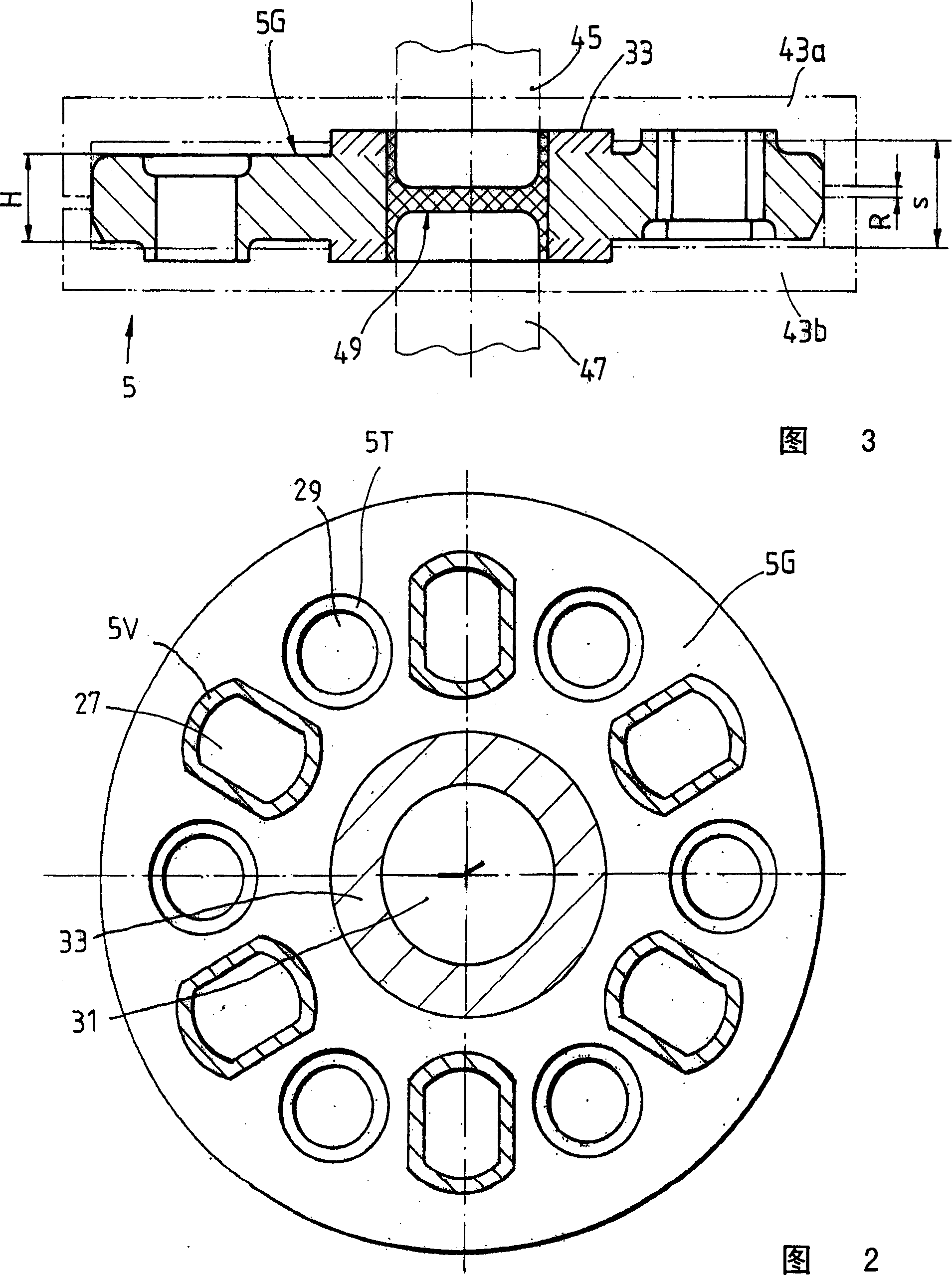

[0019] FIG. 2 shows a plan view of the piston 5 in the finished state. Projecting from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com