Warp knitting machine

A technology of warp knitting machine and traction parts, which is applied in the field of warp knitting machines, can solve the problems of damage to traction parts, confusion, etc., and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

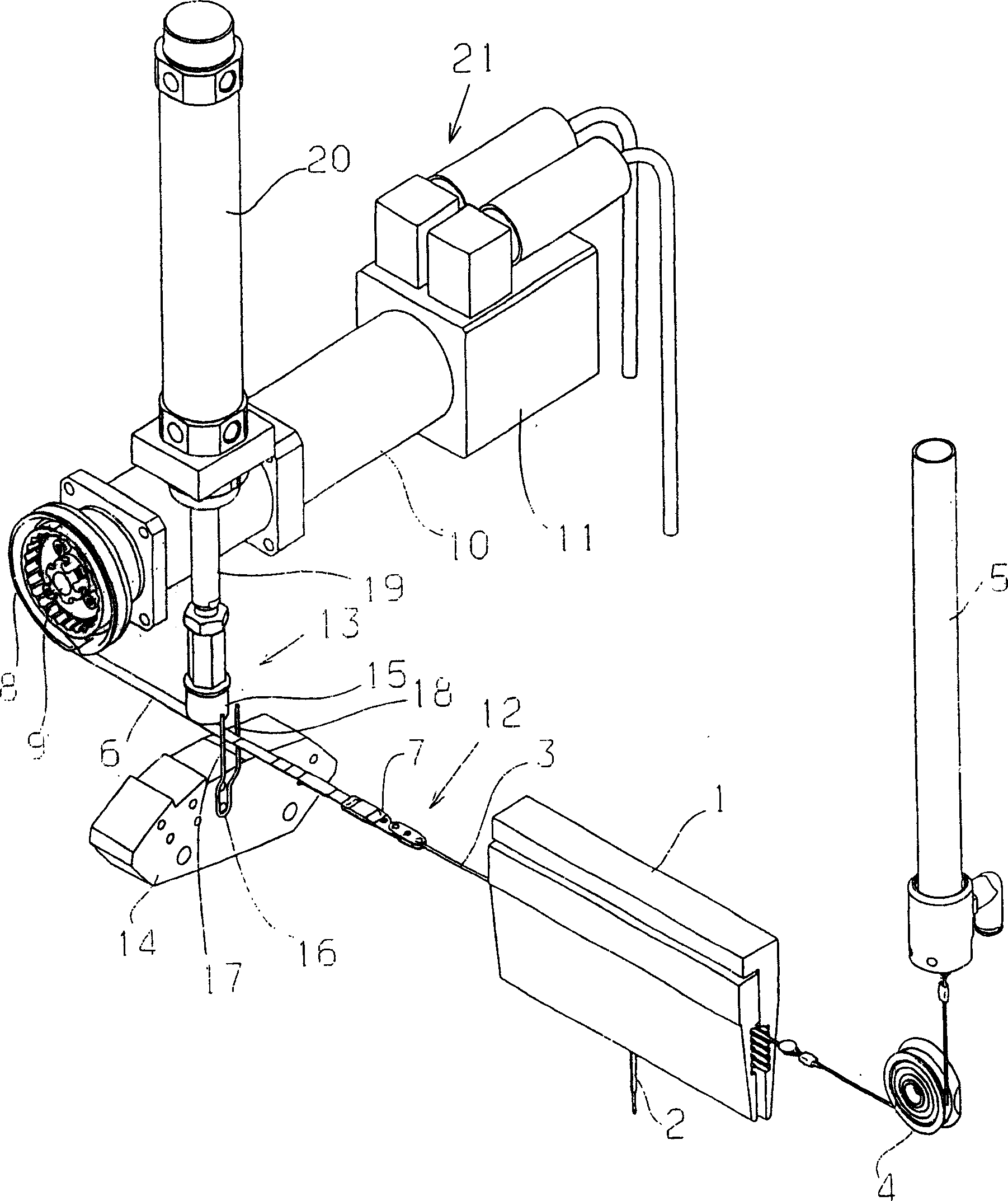

[0030] figure 1 A partial schematic view of a warp knitting machine with a drawing element 1 with a thread guide 2 is shown. There are generally a plurality of flower bars on a warp knitting machine. Each flower bar usually has more than one yarn guide 2 again. while in figure 1 The warp knitting machine partially shown in the center serves to simplify the description.

[0031] Yarn guide 2 is fixed on the wire rope 3. If the wire rope 3 moves back and forth, the yarn guide 2 also moves back and forth in the traversing direction. The traverse direction extends parallel to the longitudinal direction of the steel wire rope 3 .

[0032] at one end ( figure 1 On the right side), the wire rope 3 moves to the tensioning device 5 through a guide roller 4 . The tensioning device 5 produces a tensioning force on the wire rope 3 which is independent of the stroke length. For this purpose, the tensioning device 5 is, for example, a compressed air cylinder.

[0033] At the other ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap