Method of manufacturing semiconductor device and manufacturing apparatus of semiconductor device

A manufacturing method and technology of a manufacturing device, which are applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of dull blade, increased incidence of defective semiconductor components, and easy access to component areas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

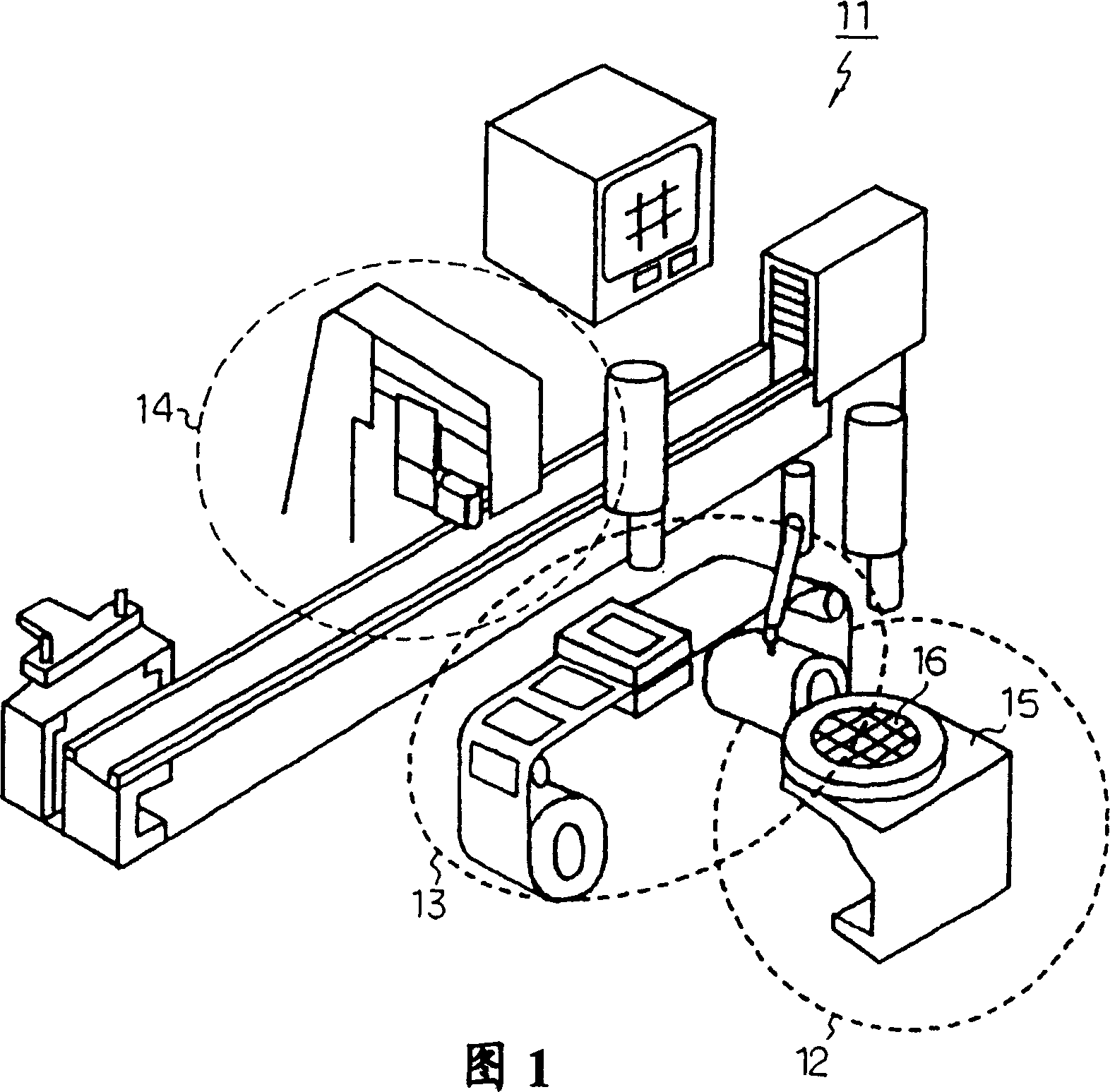

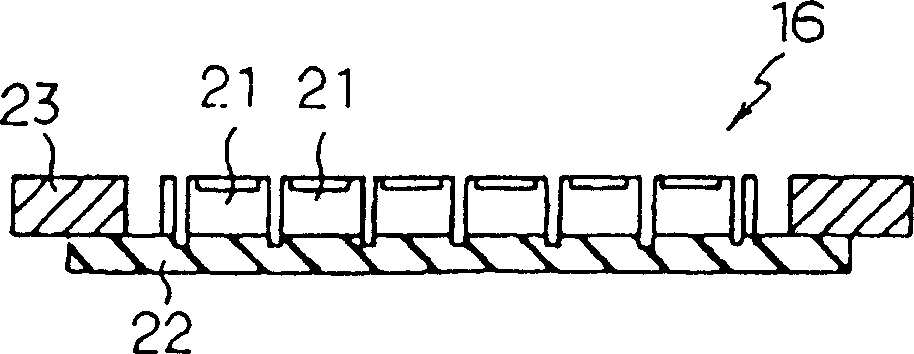

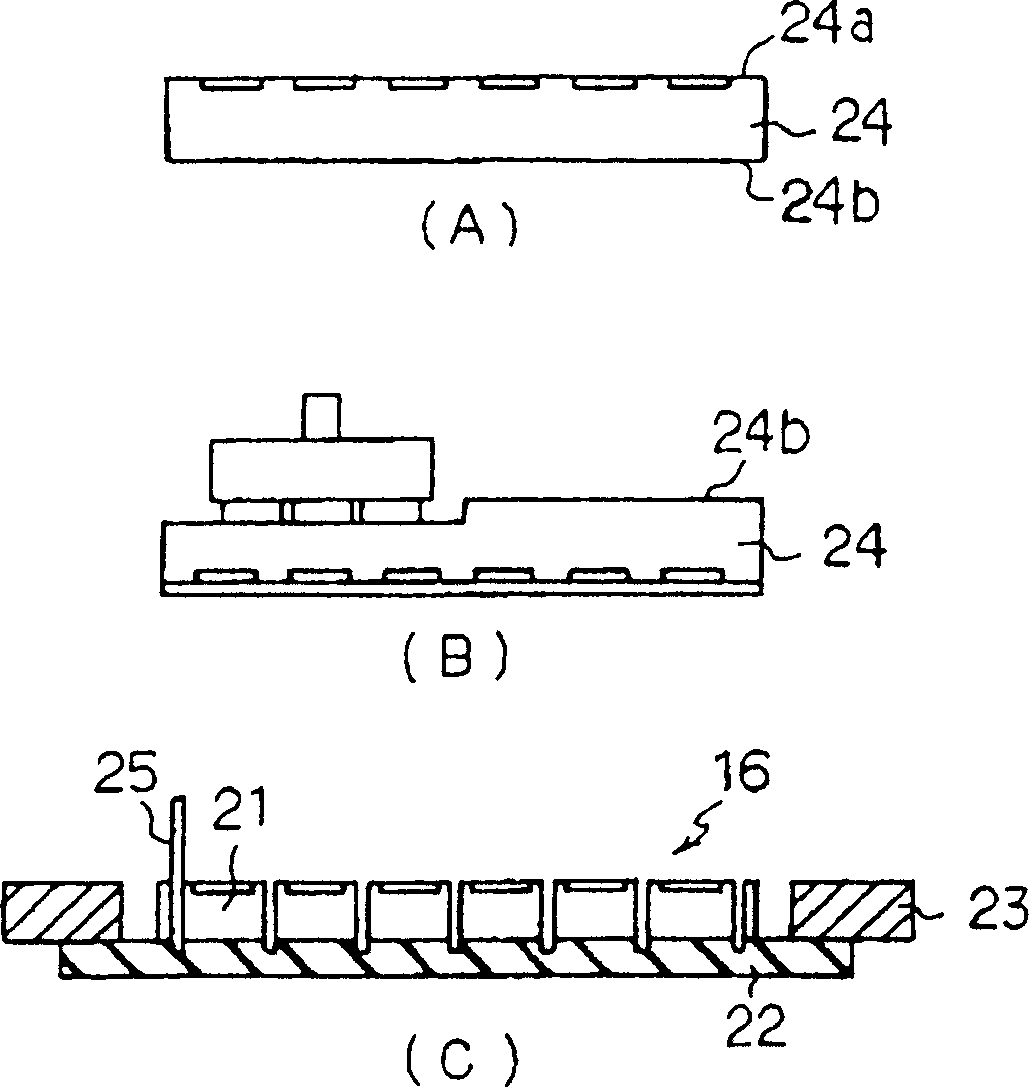

[0054] According to an embodiment of the manufacturing method of the semiconductor device and the semiconductor device of the present invention, first, the semiconductor wafer having the element region formed on the surface portion is cut and divided into individual small pieces of semiconductor elements. In this state, the semiconductor element is held by the holding member. Next, after the semiconductor element is picked up from the holding member for each element, the element bonding film which is separated into pieces according to the shape of the element is attached to the back surface of the semiconductor element. Thereafter, the semiconductor element is bonded to the base material for semiconductor device formation using the element bonding film attached to the back surface of the semiconductor element.

[0055] In one embodiment of the present invention, a holding tape such as an adhesive tape is used as the holding member. In addition, instead of the holding tape, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com