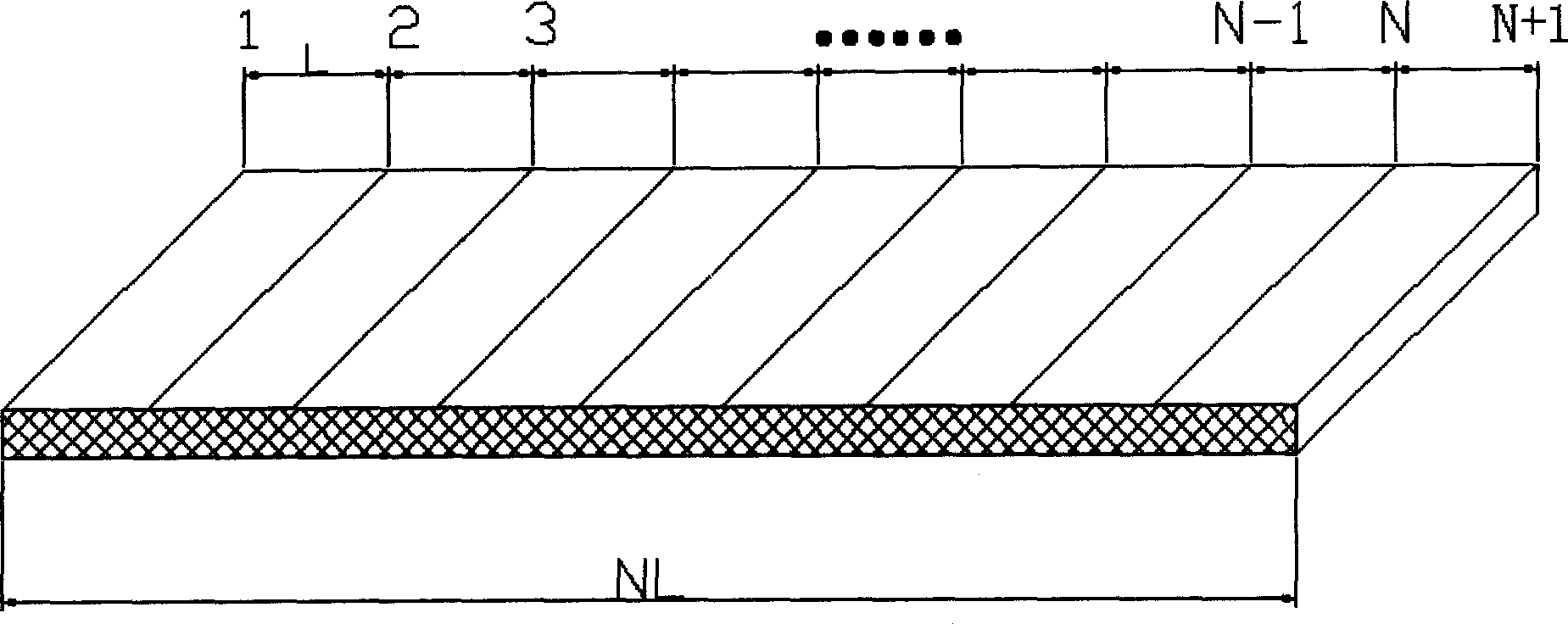

Method for measuring critical current homogenity of every portion for super conducting strip

A technology of superconducting strips and critical currents, which is applied in the direction of measuring devices, magnetic properties measurement, and material analysis through electromagnetic means, which can solve the problems of superconducting strip damage and long length of superconducting strips, and reduce equipment The effect of cost, small workload and high spatial precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

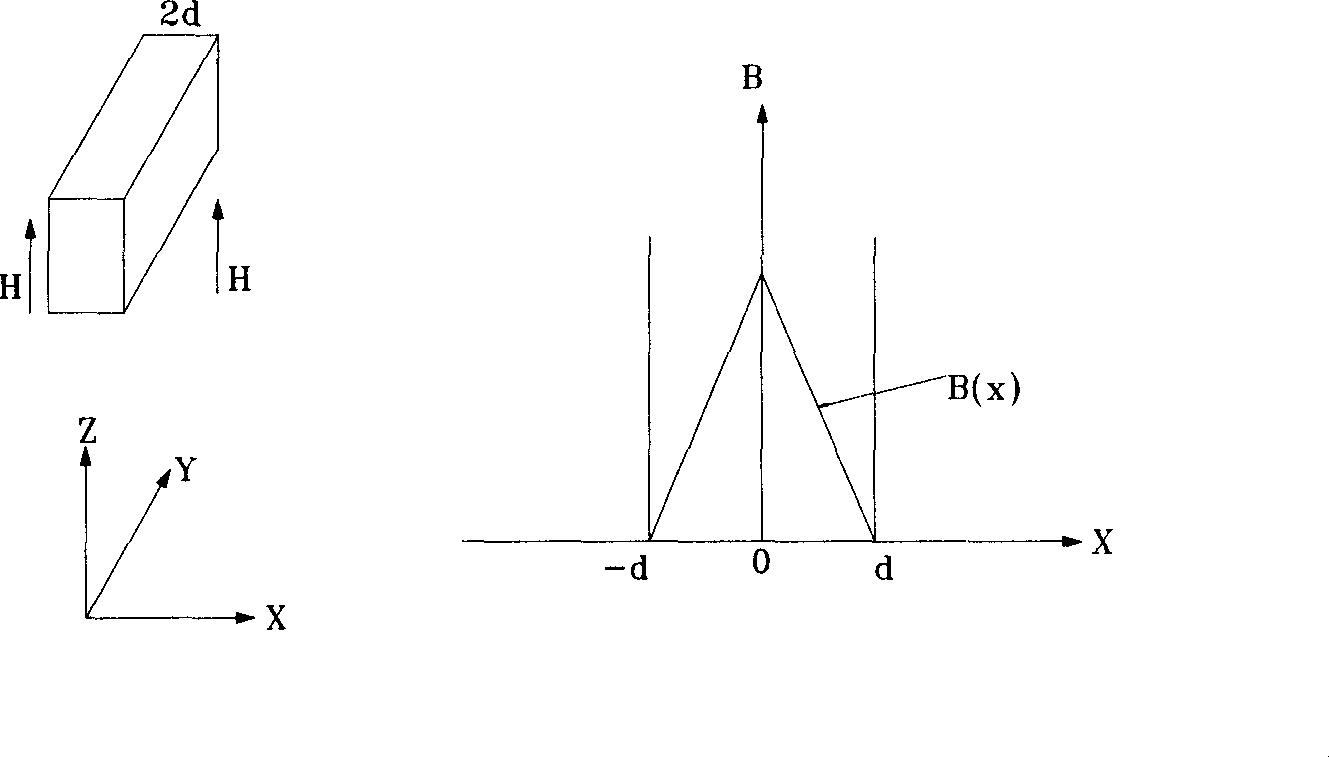

Method used

Image

Examples

Embodiment Construction

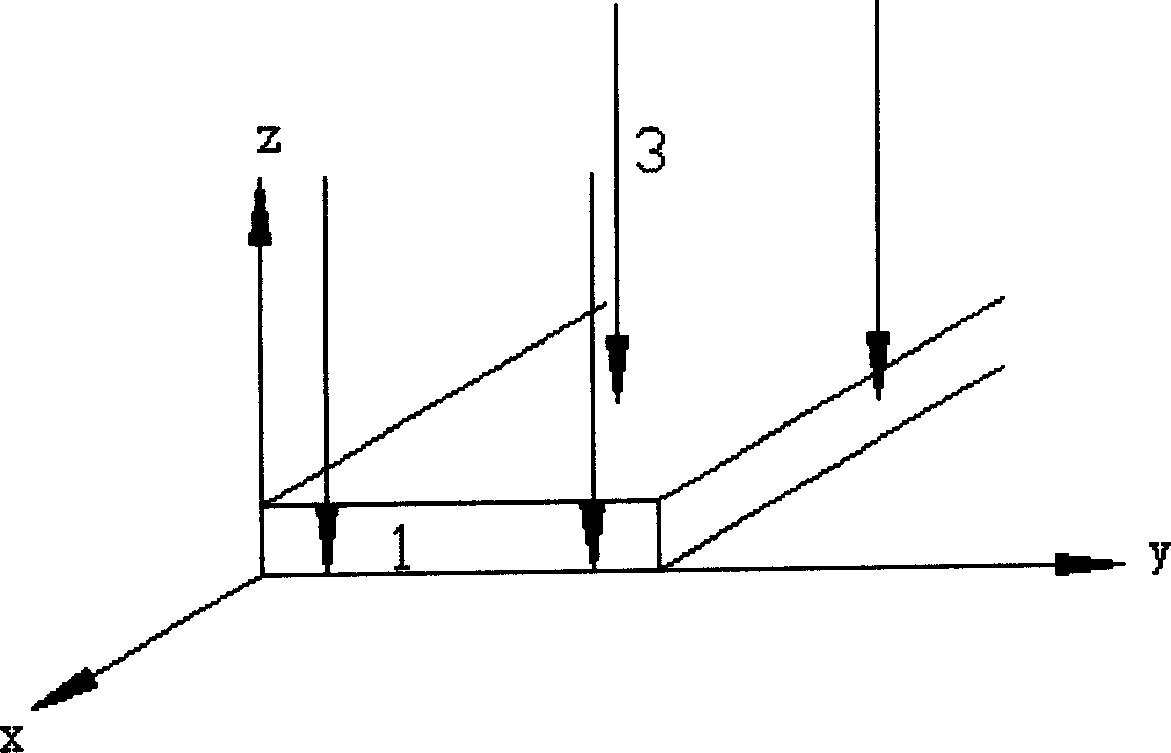

[0061] Figure 3a In order to apply an external magnetic field to the superconducting strip, the external magnetic field 3 is perpendicular to the superconducting strip 1, and it is required that the external magnetic field 3 is larger than the penetrating magnetic field of the superconducting strip and is a DC back field. The applied magnetic field 3 consists of Figure 4 The back field magnet 4 is produced, the back field magnet 4 is a pair of copper wire wound multi-layer solenoid coils, and the back field magnet 4 is connected with a direct current to generate a direct current magnetic field, and the magnitude of the external magnetic field 3 can be above 400Gs It meets the requirement of measuring the critical current uniformity of each part of the existing superconducting strip.

[0062] Figure 3b In order to measure the residual magnetism of the superconducting strip, the direction of the residual magnetic field of the superconducting strip is also perpendicular to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com